elmoleaf

Members-

Posts

77 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by elmoleaf

-

I found this hammer head with a metal detector many years ago at homesite that’d burned in the 19th century. Seems to be cast and has lots of corrosion pits, included big one on the main face. Sides are chamfered, and the smaller face is not parallel to the bigger one. Not sure it’s mounted right side up or not on this handle. Is there a name for this hammer type? Would it have any use with a dished face? Thank you

-

Finished my Pelgrom tongs. Second pair of tongs ever made. Confident enough this time to punch the rivet holes instead of drilling...worked pretty well, but need to make longer punch for working safely. And didn’t use cut off bolt this time...properly peened over the ends of some small diameter rod for the rivet. Isn’t great where jaws join bosses...small crack etc..but learned enough to do better next time. Would probably leave things more round instead of squaring up the sections. These started out as a piece of #5 rebar. Drawing out the reins wasn’t fun...was using anvil edge with round head hammer.,.. had lots of dents...probably need to work the steel a lot hotter. I did try to work a lot quicker this time, since the first stage of these took forever. The most important thing is I now have tongs that can safely hold the type of stock needed for making hardie tools. And I learned a bit more about drawing out, making holes, making bosses, fire management with charcoal, using the anvil, etc.

-

Justin’s Smithing progression. [PIC heavy]

elmoleaf replied to Justin Topp's topic in Member Projects

Nice job. -

Nice. I like the simplicity and flow of the lines.

-

Started on my second pair of tongs ever...making Pelgrom style to hold larger stock...will have ends curved to allow them to curve around rr spike heads etc. Learned a lot and will need to learn more. Forming the bosses or drawing out looks easy when you watch video an experienced smith at work! Not so easy when you try it. I found having paper sketch of the design and process notes pinned next to my anvil was useful.

-

Old topic...but here is a picture of a clinker I fished out today from charcoal fire. The charcoal was scrounged from scrap burned in a fire pit. The wood only had a few staples and occasional broken off nail. Nonetheless between those and the ash & scale, the wood charcoal still formed a big donut clinker after about 3-4 hours of burn time.

-

5 gal bucket retort for making charcoal

elmoleaf replied to elmoleaf's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Here is a link to very short video of the retort in action. -

In addition to the new forge fire poker I posted elsewhere, did some experimenting with some stainless utensils, with thought to assembling into candle holder or something. They lose heat incredibly fast... have to bend and shape super quick. Thinking of rivets or more likely copper wire wrap to build up these type of components into a single piece.

-

5 gal bucket retort for making charcoal

elmoleaf replied to elmoleaf's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Yes Frosty all of the above noted. It is only using about 2 five gal buckets of wood limb/junk wood to fire for 3 hours max. If I do other things outside while tending, it’s not unreasonable effort vs return for my situation. For decent volume of charcoal to time/effort, a 55 gallon drum is certainly the way to go. I will upscale to new retort if I continue with charcoal. -

What did you do in the shop today?

elmoleaf replied to Mark Ling's topic in Blacksmithing, General Discussion

New fire rake/poker for my forge. Made from some gnarly rusty rebar. Am enjoying the new anvil. Tried also making hardie hot cut...but ended up quitting on that...too dangerous without correct tongs and fire management issues I need to figure out. -

My brother gave me a big steel angle...1/4 to maybe 3/8” thick with 4 holes one side...and some old mower blades.

-

This is the 1913 80 lb Fisher I got last month...it too seems to have original paint. Only signs of use are some small far side chips and a minor horn ding or two . So far weather etc has conspired against me for chance to use it, though I have now got it cleaned up and stump mounted.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

5 gal bucket retort for making charcoal

elmoleaf replied to elmoleaf's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

The pipe diameter on mine is a bit small....was a tradeoff between reduced flue functionality and maximizing volume inside of can for charcoal....and it was only pipe I had available. The fire below the can also exhausts a bit thru the sides of the loose brick stack holding up the can. Furnace cement is also cheap temp seal for the pipe penetration and is easy to break apart when done cooking. -

It didn’t follow me home...was walking by Northern Ave bridge in Boston and spotted what look like enormous leaf springs and some plates. You folks got me in habit of looking for cast-off steel everywhere! Amazing amounts of rivets etc in this bridge...all destined for the scrap heap when it gets demolished in a few years.

-

Blacksmithing gems and pearls

elmoleaf replied to Glenn's topic in Blacksmithing, General Discussion

Common purpose is the missing rivet of this relationship. Until we realize this, and join again respectfully in good-will to labor together, our country will remain as dysfunctional as one-handled tongs. -

Show me your anvil stands

elmoleaf replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Got my 80 lb Fisher mounted. My aim was to have the anvil functional quickly, rather than making a big long project out of the log. This is a heavy oak log I’d been saving...was painted with some extra latex paint originally to seal end grain and keep out the moisture /bugs ( last summer I’d had to eradicate some carpenter ants that’d started in on a soft area on one end). I have to move this outside to the lawn whenever I use the forge, so sealing bottom will help keep out water etc. Last week I cut down log end to level it off and got sides trimmed/tapered down to allow close access to the anvil. Top needed some chiseling to fine tune for anvil footprint. Dumped some BLO on fresh cuts to seal, since didnt want to wait for paint to dry and it’ll all get dirty and dinged up soon enough. While it would’ve looked good to strip all the wood down and smooth it out etc, I’d rather spend my time on other stuff. Hold down is a length of spare chain with 4 lag bolts sunk in at a slight angle. Again, nice forged hold downs would look cool, but I really would rather use my time to make some new tongs, as well a proper punch and hot cut. There is also some silicone under the anvil. -

Another source of magnets is old computer hard drives (need to destroy the drive...and it needs to be one of the old spinning platter types). While not big, the magnets are pretty strong and might be used in combination with some metal to dampen the ring?

-

5 gal bucket retort for making charcoal

elmoleaf replied to elmoleaf's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Yes...was trying also for simple design with materials on hand. Definitely wanted design that’d burn the off-gassing to avoid smoking out the neighbors. I have some leftover wood stove gasket that I’ll add to the lid...hopefully by burning more of that smoke, it’ll give more heat towards cooking the wood and reduce need for external fuel...which has been about two five gal buckets of sticks and bigger chunks of dry blown down limbs from the woods. Wood being cooked is old pine 3/4 boards, split and broken down to 2-3” chunks via hatchet. -

This is small wood charcoal retort made from a metal stain bucket and a piece of tube from a swingset. I dont have a welder, so this is super simple. No big hole drill either ( hole in lid and bottom of bucket made by drilling bunch of small holes and chiseling thru to connect the dots.) The tube came with that change in diameter. So once tube put thru bottom of bucket, a simple cross rod on bottom outside holds it snug to bucket bottom. At the bottom portion of tube inside the bucket, i drilled a bunch of holes to let wood gas out of the bucket and into the tube to burn off. The lid simply drops down on top and gets covered with dirt for insulation and to help seal around the pipe. I also drizzle some sand around pipe inside the bucket to also seal that joint. The lid doesnt have a gasket so is somewhat leaky, but top of pipe still roars like a rocket after about 30 minutes, and is generally done after about 2.5 hours. I have this set up on a small semi circle of bricks to make a small burn chamber under the bucket.

-

The new price standard for anvils

elmoleaf replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

This is mine cleaned (wire wheel and boiled linseed oil.) I felt the Fisher brand and condition warranted a strong offer, along with it being right for my needs. Was 86 mile round trip drive to get it. Like many, was discouraged by high prices, but was ready to jump when opportunity arose. -

The new price standard for anvils

elmoleaf replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

I just paid $3.75 /lb for a barely used 80lb Fisher. It was originally listed for $900, and dropped in price and sitting at $500 for a week. I made an offer of $300 that was accepted. All those moon money listings for junk (Instead of prices actually realized) seem to skew other sellers sense of value when they decide on listing prices. -

After about 7 years of dabbling with blacksmithing on a small soft piece of steel, I bought a traditional anvil. I had progressed a bit in the things I’ve been making enough to realize having both a horn and option to use hardy tools would be worthwhile investment in making some tasks easier with probably better results. It took a while to get to this point, in both hammering away and debating if a part time hobby was worth the spend. For at least a year I’d been scanning ads, asking people about anvils etc. Saw the same abused overpriced junk everyone here has mentioned. Looked at new, but couldn’t bring myself to spend that much more on a part time hobby. Anyway, decided to scroll a bit deeper on Facebook marketplace, and found a barely used looking Fisher 80lb made in 1913 that had originally been listed for something like $900, then dropped to $500 and listed for over a week. A Fisher would be quiet for my suburban location here in Massachusetts and the size a big improvement on my current setup but still easily moved to my forging spot outdoors from the storage shed. I considered the brand and excellent condition and decided to offer what I felt would be fair price for me and for the seller, who judging by original list price was unsure about value. So I offered $3.75 lb ($300) and the seller accepted. The seller said the anvil came with the property when they bought their home. I asked if they happened to also have any related tools for sale, but there weren't any. I made sure to bring a small ball bearing and ruler to test rebound before forking over any cash. I found rebound about 85% at least over the entire face. After careful inspection, I handed over the cash and brought it home. Other than some small chips, and some minor dents on the horn, it appears hardly used. The black paint seems original. I’m happy part of the edge is already dressed with a nice radius ( a file skated over the chipped areas, so not sure how I’d ever add any radius myself without power tools anyway). I used a light wire wheel to remove the rust and put on a light coat of boiled linseed oil. Now I just need to mount it on a stump I’ve been saving for about 6-7 years for just such an anvil. I figure if I ever quit the hobby, I should be able to get my money back on this anvil, and if my interest continues and deepens, I can always save my pennies to add a heavier anvil down the road. I’m very glad though I started right in on the hunk of steel I had at hand at the time, rather than overspending years ago before I’d had time to learn what I needed.

-

This is my latest project....railing with some wood to support a glass top on an 1892 sewing machine table that’ll be used as a bar. Wire is from an old mattress. Brass brush worn out so used a bit of paint for the highlights. Challenging to make multiples of a part all consistent size. Wished I’d been more careful with consistent wrapping of the supports and how the leaf wraps/sits relative to the horizontal, but was too worried with losing heat/speed needed to get them wrapped. Happy everything reasonably straight and consistent, and happy to preserve the sewing machine ( saved the removed top so it can be put back in future if needed) . Also found it challenging to work with the long piece...kept rotating in my hands etc until I put vice grips on it for added leverage point.

-

Back after hiatus...made a handle for a small shed. 16” long piece of rebar. Using some wood charcoal made on the quick in my firepit. Anvil is still small piece of steel scrap on end...but redid the mount and painted stump to help cut down on bugs (was stored outside, now in a shed) I had forgotten how challenging deceptively simple objects can be...getting leaves similar size, getting matching curves. I have a tow hook need to get secure in the vice to use as a horn...that should help with curve making....and of course needs lots of PRACTICE!

-

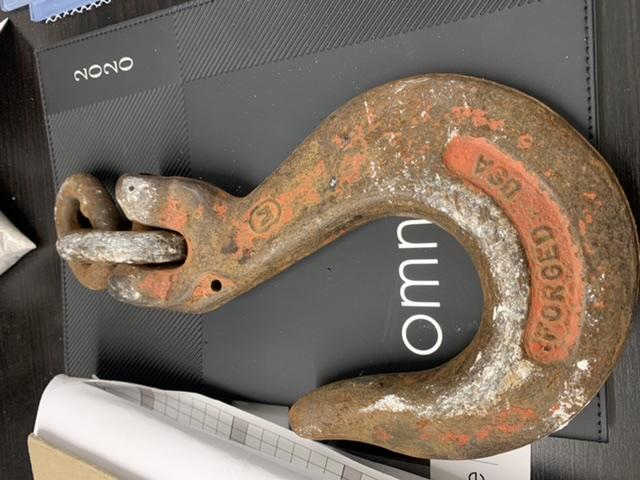

Walking to work downtown Boston this morning... found this sitting in gutter next to the curb. Hundreds of people must have already walked right by it, but I picked it up. CM Herc Alloy hook, about 7” high.