-

Posts

60 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Wrought Iron Farm

-

What kind should I buy?

Wrought Iron Farm replied to Wrought Iron Farm's topic in Blacksmithing, General Discussion

I don’t want to use high carbon for my basic projects. I’m wondering what kind of mild steel to buy. I live by Chicago so there are abunch of steel factories within spitting distance. Admiral steel is where I go mostly for 1095cra. I want like 3/8 and 1/2 mild bar stock but don’t know what to look for. -

Newbie here, I’ve been making knives for about 6 years and a glass blower for 20. I’ve been tinkering with a rr track and coal forge made from a brake drum for about 6 years as well. Just messing around with rr spike I get from a scrap yard here. I just stepped up my game and got a gas forge a 100lb and a 200lb arm&anvils. I have bought 1085-1095 for knives. I want square stock for hooks, leaves, keychains and tongs but don’t think it needs to be high carbon. What kind of square or round stock should I buy for basic projects? Any info would be greatly appreciated.

-

No markings on anvil, need help identifying

Wrought Iron Farm replied to Ocelot's topic in Anvils, Swage Blocks, and Mandrels

-

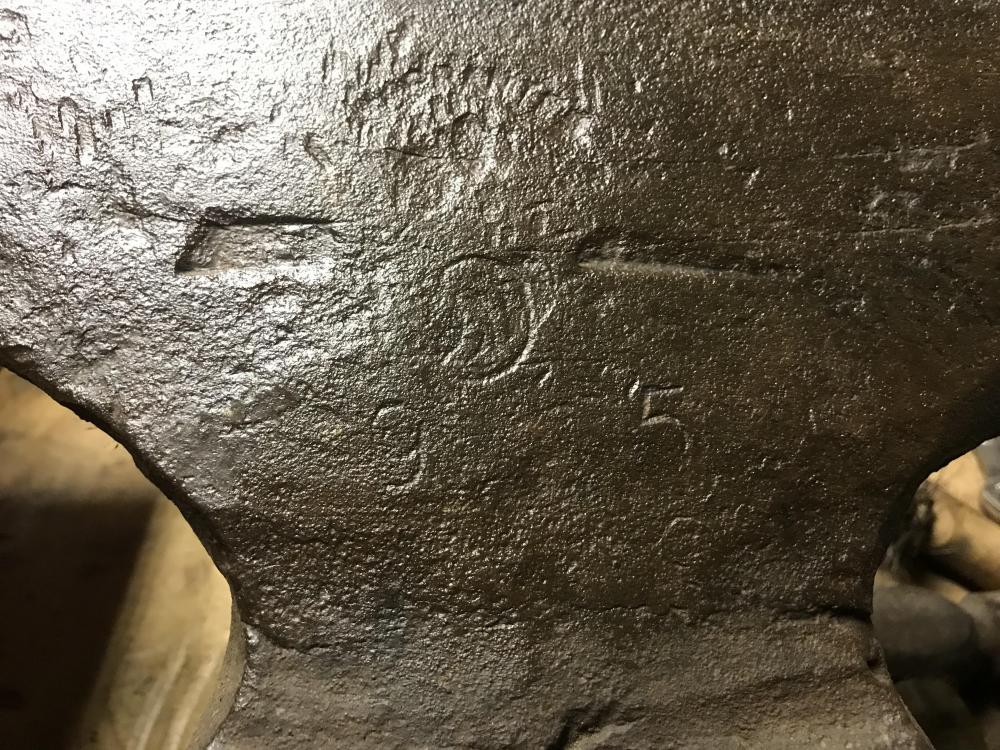

Hey guys, I need help trying to date my first anvil. I found it on Facebook for $200. It’s definitely a step up from the railroad track I’ve been using. Now I just need to upgrade the torch to a forge and I’ll really be in business. Anyway the face is awesome and has great rebound but this thing must have sat in a field for 50 years. All of the holes below the waist were packed with dirt. The logo is barley visible and the dating marks are almost nonexistent. I believe the numbers on the front foot are 12832 or 12632. Here are some pics.

-

Not sanding after heat treat

Wrought Iron Farm replied to Wrought Iron Farm's topic in Heat Treating Knives, Blades etc

-

Ok I have made around 13 knives and just made my first chef knife out of 1075. I shaped it put the bevels in and sanded it with 220 then 400. After it was smooth and most scratches were out I heated with my torch till non magnetic and quenched in oil. I then sanded the scale off and put in the oven at 500 for two hours. It came out this beautiful blue purple gray copper colors. I would like to leave it like that if it's possible, and just put the final edge on it after I pin and epoxy the handles on. I guess the question is would those colors hold up or would they rub off or would it be susseptable to rust?

-

Heat treat 1095cra

Wrought Iron Farm replied to Wrought Iron Farm's topic in Heat Treating Knives, Blades etc

I went for it and used my torch this time and quenched in oil. It's hard XXXXXX now the file just passed right over it. But now the blade is warped it has a slight bow to it. I was going to do two cycles at 425 and try to straighten it after second heating? I appreciate the help btw guys -

Heat treat 1095cra

Wrought Iron Farm replied to Wrought Iron Farm's topic in Heat Treating Knives, Blades etc

I read somewhere online that said put it the kiln around 1200. I have been looking for it and can't find it now of course. It might have been a YouTube video now that I think about it. So I should put it in cold and bring up to temp? Also can I reheat this knife? -

Heat treat 1095cra

Wrought Iron Farm replied to Wrought Iron Farm's topic in Heat Treating Knives, Blades etc

Should I reheat and quench again? I don't want to just give up on this one it's one of my best so far. -

Heat treat 1095cra

Wrought Iron Farm replied to Wrought Iron Farm's topic in Heat Treating Knives, Blades etc

Yes there was a carbon layer on the blade. I don't forge my own blades I get admiral steel 1095cra. -

Heat treat 1095cra

Wrought Iron Farm replied to Wrought Iron Farm's topic in Heat Treating Knives, Blades etc

Vegetable -

I'm having a hard time hardening my steel. I'm a glass blower so I have an electrics kiln that I use for glass and now heat treating. I set my digital pyrometer to 1575 and when it hit 1200 I put the blades in. I let it hit 1575 and tested the magnativity of the blades and there was none. I took out the first blade after letting it soak for 10 mins then quenched in oil and let sit till cool. Did the same with blade two. I tried to file it to check hardness and the file cut right thru. So I take it it didn't work? Any help would be appreciated. Thanks Also it was 5/32 x 2" x 8" long

-

Thanks Benton here are finished pics.

-

Here are a few pics. Im super stoked how its turning out, the timing it awesome on it. I'm heat treating the blade right now so I should be able to finish it tomorrow. Its 1080 with high figured maple handles and stainless pins that I plane to peen. I will post more pics of finished knife. trim.A0C0464E-2B37-4869-A3D3-CF978D3FB54F.MOV

-

rail track anvil, hardy hole alt.

Wrought Iron Farm replied to joreve's topic in Anvils, Swage Blocks, and Mandrels

Im no expert by any means, but this is whatI have. I got that whole set up at a scrap yard for $40. That plate is what the RR use to connect the track, so the track anvil fits perfect in the groove. It has 5 square holes and I used 4 inch lag bolts in two holes to lock down the anvil. So there are 3 holes left for hardy holes. Hope this helps. -

My scrapyard anvil

Wrought Iron Farm replied to Wrought Iron Farm's topic in Anvils, Swage Blocks, and Mandrels

We had a face shield and she took it off because it kept steaming up. Believe it or not we were using our brains. She is also a trained union iron worker so she knows and follows OSHA regulations. I appreciate the concern tho guys. -

So I went to the scrapyard the other day and grabbed a two foot section of track. I also scored ten spikes and a plate that the track fits in. Ill throw a pic of that up tomorrow. So I cut through this RR track with my angle grinder, it took me like 6 hours and I busted my Milwaukee grinder. I had my friend helping and she went to cut in when we were 90% done and the disc broke. We tried to take the locking nut off and it was jammed. So I took a pipe wrench to the nut and broke the lock on my grinder. But she brought over her grinder today and we finished the cut. It helps to know a chick thats a XXXXXX Iron worker...

-

Newest pattern welded billet for knives.

Wrought Iron Farm replied to kayakersteve's topic in Knife Making

15x3=45folded once=90folded once=180 layers? -

Scratching my head, urmmmm what happened to my video I posted?

- 3 replies

-

- Brake drum

- forge

-

(and 2 more)

Tagged with:

-

I'm sure you guys have seen many of these but I'm super stoked to show off mine. Let me know what u guys think.

- 3 replies

-

- Brake drum

- forge

-

(and 2 more)

Tagged with:

-

I have been blowing glass for 16yrs now, when I started there weren't many lamp workers out there. And the lamp workers you met were all secretive about their techniques. Then I discovered a book called contemporary lamp working, it was two books and it was considered the glass blowers bible. It explained everything from flame control to tools and techniques. My question to you all is the a end all be all book of blacksmithing. Im a total newbie that has never put hammer to hot iron. I started making knives by cutting knife shapes out 1/8" steel with my angle grinder and heat treating them with my glass blowing torch and kiln. Then I started watching youtube videos about blacksmithing and figured I would give it a shot. I would like to find a book that had a little more direction then youtube. Any suggestions would be greatly appreciated.

-

so glad i found this, this is exactly what i wanted to make.

-

Looking for a place to forge

Wrought Iron Farm replied to Brett R.'s topic in Blacksmithing, General Discussion

Yeah I think that's the place. -

Looking for a place to forge

Wrought Iron Farm replied to Brett R.'s topic in Blacksmithing, General Discussion

Hey brett, I have one lead for you to follow. I used to work at a place called chicago hot glass and there was a forge right next store. we all used the same entrance to the building. I'm sure if you look chg you can call and get the name and # to the forging/blacksmithing shop. I wish I could go back there but there are some crazy stalker chicks that work in the glass shop so beware. good luck and let me know what u find out -

Forging old stainless butter knives

Wrought Iron Farm replied to Wrought Iron Farm's topic in Knife Making

No I try to buy the solid knives. They kinda are a multi purpose keychain. The look cool and there solid so it can be used for defensive purpose. Also if you get stuck in a car you can use or to brake out the window.- 18 replies

-

- Knives

- Forging stainless

-

(and 1 more)

Tagged with: