-

Posts

329 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Illinois

Converted

-

Location

Rockford, Illinois

-

Biography

I still live. . .

-

Interests

What the sun touches and beyond. . .

-

Occupation

Varied

Recent Profile Visitors

6,211 profile views

-

Rockford, Illinois is the place where I lived recently. You're right, Chris, I'm not a member of this community, I'm just concerned about it enough to try and point out an obvious lack of proactive measures regarding the display and distribution of information pertinent to said community. Glenn, two questions, 1: Why don't you already have the CDC information post you replied to me here posted on every section here with blacksmith specific issues, like how to insure the bottle opener made for your neighbor won't potentially get them sick? 2: I'm done, this place is exhausting, almost entirely due to how I approach things and people. So if you're able, will you please delete my account? I've looked through the account setting and can't find where to do that.

-

Frosty, thanks, but my concern for the future of my account here is way less than my concern for people's lives. I'm staggered by the dismissive nature with which this pandemic is being treated by so many people that are in positions to help protect those in their community. But, maybe that's because I recently lived in a building, that during the Spanish Flu, had dozens of corpses stacked in it like cordwood. And that my dad is nearing 80 and on chemo, a combination of which is not remotely unique in this world. Less people in his position would be killed by this, if more people in positions of authority took some sort of responsibility for the wellbeing of people in their communities. "If they do not know or show symptoms they have no reason to take any precautions above normal care." This approach kills people. Straight up, it kills people. It already has, and it will continue to, kill people.

-

Data: People who are carrying the virus, but not yet showing symptoms have a higher viral load than people who are showing symptoms. The range of incubation time is between 2 days and over 11 days, some reports indicate up to 15 days. Scenario: An order for wall hooks is made, and it's to be shipped to the customer. What must the blacksmith do to ensure that, if they are infected and not yet showing symptoms, they are not passing on the virus to the customer, and thus people in contact with said customer, when they handle and package the finished work? That's just one scenario where blacksmiths could spread this virus and not even know it.

-

Where is the "READ THIS FIRST" thread stuck? Is it where "adults will scroll down to see"? This is a dangerously ignorant statement. What of forged objects sold to others? That you're an administrator here, who can't take direct criticism without responding spitefully about an issue of such critical worldwide importance is highly disturbing.

-

I see, yes, it's been moved to the "everything else" section. I'd never noticed the previous thread on the coronavirus here before, because it's a tucked away little corner of this site. Speaking of being direct, it seems more logical to me to have an official sticky in the heaviest traffic area with blacksmith specific information, such as how to avoid enabling the spread of this pandemic and irresponsible to put such a potentially vital discussion in a much lower traffic area. To be clear, I'm not talking about the thread I started, but official blacksmith oriented covid information in general being a sticky in the heaviest traffic area of the site.

-

Not sure where to put this, but since many people here will be handling steel handled by other people, or passing their work on, this seems relevant. The link contains some good information but turns political toward the end of the article. For that reason it has been removed. And a link to the non-peer reviewed study referenced. https://www.medrxiv.org/content/10.1101/2020.03.09.20033217v2 Click on the "download PDF" to view it in full. There hasn't yet been time for people to duplicate testing, so this test only gives an idea of how long COVID-19 or SARS-CoV-2 survives on surfaces, but it should help people continue work while minimizing the spread of the virus. If other people have found more information regarding the above, please share.

-

Frosty, thanks, "From Completely Different Perspectives" is my middle name, or at least it should be. Yes, saying the same thing, but from completely different directions, the problem solving equivalent of the pincer movement.

-

Cool, sounds like you're well on your way!

-

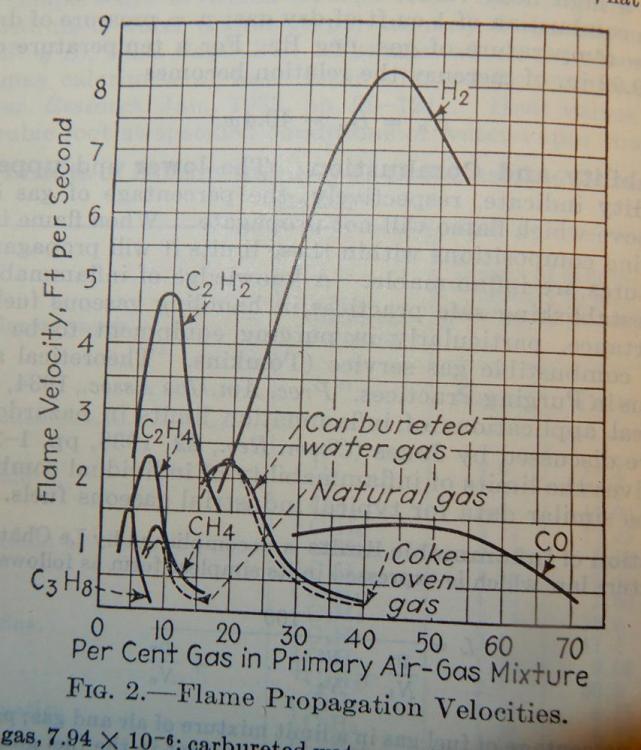

Yeah, friends Frosty, no worries. I'm autistic, that's my brain issue. Which for me means that I'm naturally communicating at either a 2% or 98% depth, both of which, in their own ways, can be extraordinarily problematic. Which requires constant vigilance from me to put that into a more moderate range that's socially acceptable. I'm glad both of you guys survived your traumas! As I think we all know a bit too well, in our own different ways, that sometimes, life can be death. What I was referencing via the video link, was that of the principles of resonation and the production of sound being universal. In the examples in the video they're intentional and being produced by a powered resonator, in the forge they're unintentional and being produced by nature. In both of them, the sound is being projected into the air via resonating flames. The reason for the sound going away and coming back when you adjust your mixture is due to the flame front velocity. That is, the speed with which the flame can travel through a combustible mixture of gasses. Which is influenced by the fuel type, presence of dilution gasses such as nitrogen in the atmosphere, density of the mixture, temperature of the mixture and variance from the optimal ratio of gasses for complete combustion. Here's a chart from Marks' Mechanical Engineers Handbook that will illustrate the mixture issue. C3H8 is propane. As we can see, it has a tight range of gas to air ratio, in which its flame velocity drops by 1/3 rapidly in either direction, either rich or lean. And we can instantly see why burning pure hydrogen is so dangerous, as well as why a hydrogen flame is so compact. As Frosty pointed out, the resonation is being caused by the flames going back into the flame holders. That's because the air/fuel mixture is traveling at a lower velocity than that of the flame front. Thus, why your burner quiets down when you adjust the air/fuel ratio in either direction. Since by doing so, you're lowering the flame propagation velocity. The resonation itself is caused by the flame "supercharging" the orifice. The orifice has a natural contraction inside of it, caused by the compressible gas flow through it, so that the effective diameter of gasses emitted by it looks like \_/ with the orifice being the top. Then that high velocity spray expands when it gets out. So, an orifice like this has a contraction/acceleration and then an expansion/deceleration as the gasses reach it, pass through it and leave it. A flame burning back into it will "flop" back out, because the burning gasses are being heated, thus they are expanding, thus when it starts to enter the orifice, the flow through the orifice will accelerate due to the expanding gas, which in turn slightly lowers the pressure behind the orifice, which will increase the flow through the mixing tube to the orifice, thus, pushing the flame back out. This is a series of pressure waves. The pressure rise and fall inside the large diameter mixing tube will be very slight, but as it nears the nozzles, that rise and fall will be greater, at the nozzle it will be the greatest and quickest. This can be observed in slow motion with a typical propane soldering torch or bunsen burner if it is put on a very low flow so that it goes "whop, whop, whop" as the flame dances on the nozzle. If the orifices are large enough and the flow is slow enough, it can dance back a significant distance behind the orifice until the accelerating capacity of the flame and general modification to the flow rates at various points of the burner by said backtracking flame have done enough to push it out. But it will generally be doing this in a rhythm, sometimes very slow. If, however, the air/gas mixture reaching the flame holder has a significant inertial energy, and the flame propagation velocity is only just higher than is the velocity of the gas mixture through the nozzles, then the resonation, the flame jumping into, then being pushed out of the nozzle, will be occurring at extremely high speed, so fast, the gas pressures behind it won't have much modulation at all. High speed resonation is high cycle rate is high pitch sound. So, like Frosty said, the solution is to increase the velocity of the gas mixture through the orifices, that's generally calculated by the vena contracta of the particular orifice(s), which can vary a good bit, and the area of the orifices and the pressure of the gasses being pushed or pulled through them, in this case, pushed. The product of the gas velocity and effective port area gives the gas flow rate. All a fan does is generate a pressure differential, the size or blast area of the fan gives the potential flow capacity for a given pressure differential. That is, a large fan can be limited by a small nozzle and a large nozzle can be limited by a small fan. In general, for maximizing resistance to flow through an orifice, a smaller orifice is better. The coefficient of friction of fluids in transit are increased in an exponential manner as to the reduction of the mean effective radius of the orifice, tube, pipe, etc. Thus, if you have two plates, one with many small holes and one with a few big ones, but they have the same effective gas passage area of say 1 square inch, the one with the big holes will be more likely to flashback and make whines and howls and such. This principle is why many production combustion devices have screens and/or a porous matrix behind the nozzle. They act as minute passage resistors that allow the flame to sit right inside of the orifice but not enter and rapidly spread in the mixing chamber or "flashback". But really, just increase the flow velocity by decreasing the effective nozzle area by, as Frosty said, using smaller and/or fewer nozzles. As long as you've got a flow rate above 2 1/2 feet per second in the normal operation, there shouldn't be any issues. But too high of an orifice velocity at high burner outputs will push the flame so far away from the nozzle that it will become diluted and not be able to sustain combustion. Inside a forge that's less of an issue than in the open air though, due to everything being insanely hot inside of there. In conditions where either flashback presented a tremendous danger or a more compact flame was required, one very old trick that was used was to use very high velocities through the nozzle, well higher than the flame propagation velocity would be, and use two nozzles, with their jets impacting each other at 90 degrees. That impact zone was then the origin of the combustion zone, and the turbulence generate from said impact, kept the flame from lifting off of the nozzle and it also violently blended the air/fuel so that it completed combustion very rapidly and compactly. This effect can be witnessed with two standard propane soldering torches, holding them to make their flames strike each other at 90 deg. Granted, that's not required for a forge or anything, I just found it fascinating and wanted to share it. I'll shut up before I start going on about the issues surrounding the vaporization of liquid fuels for use in a gas burner, because that has nothing to do with this! But I am just holding back about how cool(and potentially extremely annoying) a forge would be if a speaker were introduced to the mixing chamber in such a way that its resonation was transferred to the flame, making for a really "hot" boom box.

-

I've read all of it, yes, that was over a decade ago though. It has been a long time since I've been active in a forge, so trying to help people with what I do, or used to, know, is a bit difficult. When I've read back over most everything I've posted here the past few weeks, I have become frustrated, because the conversion of my latent knowledge to words is getting all jumbled and it's all coming across as nonsense. Due to intense elaboration being required in some parts. Such as lighting the anthracite coal, the description I gave was what I did when I used it and it worked well for me, but my explanation of what I was trying to describe was very wanting. Anyways, thanks for the check, Frosty, I hadn't realized how far my active knowledge and descriptive abilities had slipped. Caleb Paul Ramsby

-

This is especially important, here, and in general too. Such as, the video link I posted to doesn't pertain directly to resonation in a blacksmiths forge, but generally to the scientific principles of standing wave generation in tubes that are transferring combustible gasses to a flame holder. It'll give a deeper understanding of the principles involved, but won't directly help one with burner noise in a forge. One extraordinary resource on burner design is Ron Reil's website. Which has both general and incredibly specific information and plans for forges and burners. https://ronreil.abana.org/design1.shtml Going to a single source like that can help keep the ignorance based "knowledge" at bay, but also introduces, in general, its own bias of comprehension, since most everyone in a niech thing like this has their own sub-principles they adhere to.

-

Anthracite must get very, very hot to combust, it's nearly pure carbon. And it needs a constant supply of air to stay lit. On your next try, sprinkle little bits of your anthracite in with your initial wood fire, before it's lit. Then, as you build the wood fire up more, continue to sprinkle in the anthracite. The coal should then be catching fire along with the wood, and when you have a bed of mixed coals of anthracite and wood going, continue to sprinkle on new anthracite until you have a full fire going.

-

It's much related to what's described in the video I'll link to here. Except the standing wave in the tube, is a natural one. The solution, is to interfere with the standing wave, to interrupt it.

-

Excellent video about modifying an inexpensive hammer

Ramsberg replied to JHCC's topic in Hand Hammers

That sounds like a perfect progression to me! -

Excellent video about modifying an inexpensive hammer

Ramsberg replied to JHCC's topic in Hand Hammers

That's a good video, thank you for sharing it. My version of that for beginners, is to remove the handle, then anneel it by heating it and letting it cool in ashes. Then do the shaping in a significantly more intimate manner with files. That quiet and slow process, where one is staring at their work in the vice, helps one get to know the metal better and helps avoid massive mistakes being made in an instant with an angle grinder. It's also safer. Then, when done, harden it, which is good practice for the beginner and temper it by forging a thick rod to fit the handle hole, cleaning up the hammer so you can see the heat colors and heating the rod and putting it inside the handle's hole to spread the temper's heat. Together that's a complicated series of activities, but individually, taken slowly, they're doable for beginners and tremendous learning experiences.