-

Posts

98 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by santisandreas

-

Chinese Hammer Differences

santisandreas replied to phabib's topic in Power Hammers, Treadle Hammers, Olivers

hello phabib, your post is really helpful, thanks for all the info and the debate that took place. I am a young blacksmith practicing the profession on a regular basis as an artist and a blacksmith. Because i am in Cyprus and the people who work steel with fire are very limited there is high demand for the jobs that we can do on the anvil. As a result the profession grew and i am now thinking of getting a power hammer to help with the work overload and the fact that i am getting exhausted almost every day. At the beginning i was thinking of going for the sahinler SM50 because Turkey the country of its manufacture is the closest to Cyprus and its price was very good straight from the factory but it was still high for me. so i contacted another company who used to import all the power hammers in Cyprus back in the day. They sent their offer today for a Chinese hammer and i was lucky enough to find you discussing for the same model. The thing is that i think mine is from a different company but the model is the same. I have some pics as well to post. would you please take a look at it and tell me if you think that it is the same machine that you ordered? what did you do with the dies btw? does it come with several dies or is there the possibility to order some different types of dies with the order of the hammer? this is at an affordable price for me so i am thinking about it seriously. any help would be appreciated. the company is TENGZHOY WELLON MACHINERY CO. LTD Website address removed.- 153 replies

-

yeah i agree! the prices are everywhere about the same! thanks though! i will think about it and decide but thanks again for the info. the bates tongs are trully nice!

-

thanks a lot for the replies! i will look at bates.. anyone know anything else in the UK?

-

Hello everyone, i am starting this topic as a reference for online stores that sell blacksmithing equipment in Europe since i couldn't find a similar topic in the forum. Until now i found only Angele that has a wide variety of tools, but because of the high prices i am looking for some other stores to order some stuff needed for the forge. can everyone suggest some online stores that have tongs and other forging tools so as to look through them? if there is a similar post please tell me so i can delete this one. thanks in advance! happy august holidays to everyone!

-

Power hammer M4129

santisandreas replied to santisandreas's topic in Power Hammers, Treadle Hammers, Olivers

yes, i too agree that it is 99% a good deal considering that the school principal has no benefit on this deal. i guess it will be bought at a scrap value price which is very cheap around these parts. i am assuming that the price will be from 800 to 1500 euros max. i will take a friend to help me and get a second opinion but i don't think that i will need to run any tests. it is quite difficult to do so there at the school because it is in the occupied part of my country which adds pressure on all matters. i think the motor was at the back where the cage is cracked open, if you see in the images posted at the beginning. but i am not sure. if it is indeed missing i will buy a new motor as part of the renovation. but this is a matter that will be dealt later. i will see if the guy pulls through and we can buy it. by then i will post any news abot the subject, thanks for your advice, i will consider it when i make another visit. thanks again! -

Power hammer M4129

santisandreas replied to santisandreas's topic in Power Hammers, Treadle Hammers, Olivers

hey Alan, i didn't have any news that's why i didn't respond for some time. at the school they just said that the hammer was in a very good condition with no working problems close to new. it was in the technical department of the school for some time but no one used it and then when that department shut down they placed all the machinery outside under a shed. it appears to be sealed well so i am thinking that the damage cost by the elements will be mostly external. The man said that it belongs to the government so he will ask for permission to sell it. i tried stepping on the pedal operating the hammer and it was moving with difficulty but it wasn't stuck. I have no one to check it if it works though, do you have any clues on what to check besides what you mentioned before? how do i check that btw? i don't know what it is. the motor is missing only from what i saw until now. thanks for reading! -

Power hammer M4129

santisandreas replied to santisandreas's topic in Power Hammers, Treadle Hammers, Olivers

Hello Alan, thanks for the response. i don't know why you couldn't post a reply to my topic but i haven't changed anything to cause that, it might have been a problem of the site. i will check as soon as i am done here. Firstly i will talk about some details you pointed out. i presume that it is of little use because it was in a school for voluntary use of the students, so it is safe to say that it wasn't used very much and seems to be in a very good condition for a model from 1968. but on the other hand i am not sure for these details since i just talked to a stranger who was working there and new nothing about the machinery and what it was used for. but he said that the school is closed now and opens only on Mondays. So i will go in two days from now hoping that i will find someone who is in charge there and ask some questions about the hammer, as well as the conditions of purchase. most probably they will not ask for a lot since the school is closed, so i am guessing that i will get it at scrap price. but we will see on Monday. you are right about that test. i will try it. but unfortunately i don't know all the parts yet so i have to do more research. I have tested the pedal and it doesn't work so i am guessing that it has some minor problems from the rust and the dust since it has been sitting outside for some time now. But i will know more on Monday so i will get back to you with more soon. thank you for mentioning Olga and Sergei Polubotco, i will contact them for info sometime. -

Hello there, i am opening this post to get your opinion on a used rusty power hammer i found in the northern part of my country. since Cyprus has never really had a lot of manufacturing as an island it is extremely difficult to find a used power hammer here, but on the other hand Turkey is the country that manufactures the Sahinler hammers so i thought it would be a good idea to look for one over there.. In the end we didn't even look for it, this one was found by accident when my father was passing by. anw to cut a long story short we went to see it yesterday and found out that it belonged to a public school that is now closed for the main part but opens only on Mondays. so we are going to talk to them so as to ask for a purchase price. but before i do that i wanted your opinion if this hammer is worth the trip and if yes how much is it worth.. what is the maximum price one should pay for this? as you will see in the images below the condition is quite bad since it has been sitting outside for more than five years probably but it hasn't been opened on the inside to steal any parts (except for the motor at the back). Another thing is if you happen to know which is the manufacturer and if they produce good hammers. i did some research and found a couple of manufacturers who produce similar models and here are the links. : http://www.aref.fr/Second-hand-equipment-refurbished?formulaire_action=liste_machine&formulaire_action_args=8%2FrbUXta6g97jzK6CXgnW1JaZ6bpDEyBBjIbEpuCqkRUoIMlbNRV7WkzYctpTGDNviJYLWkio4knAjIVdigxmHrJcSMRFS6P&famille=MPF&puissance_mini=0&puissance_maxi=xxxxxxx&chercher=&nom_famille=aucune&famille_ref=Open+die+hammer++&lang=en http://scgmachinery.com/en/used-machinery-catalog/forging-hammers/ (this is the Astrakhan which is very similar to the one i found with the same model number, just a few extra letters. mine is M4129 while here is MA4129A. SO i am guessing that this is the manufacturer.) does anyone know these hammers? what can you say about them in general. After viewing the images do you think it is possible to repair this hammer and bring it back to working condition? Any advice or comments on the subject will be appreciated. thanks for reading.

-

oh that's bad Frosty. i will go check on it as soon as possible.. the work is pilling up and i cannot afford to have an injury in the middle of the job. i will visit a orthopedist doctor first to diagnose the issue and then off to the chiropractor. thanks for your replies. if anyone knows anything else it will be helpful. Thank you.!

-

hello again, i found the picture to be graphic as well, but ok, that's reality. it made me be more carefull with the angle grinder in general. Good news is that i didn't have another episode of skin rush so i think it was just a one time event.. now i am working every day almost full time and i am happy to anounce that it didn't happen again. thanks for your advice on the matter. i apply most of them now whenever i can. One other thing that concerns me is a clicking sound coming from my shoulder whenever i raise the hammer high or work with more strength than average. i think it is the nerves passing from the joints and close to my right ear. i try to avoid it by working lighter and heating the metal at its maximum but i am still worried. it doesn't happen all the time though. just sometimes when i am working a lot on a daily basis. what are your thoughts on the matter? does anyone else have this? i am going to the gym to strengthen my muscles since it is now that i started working full time so as to be able to counter such problems in the future. on another note i am a thin person almost skinny. i would appresiate it if you could advise on this matter. Thanks for reading.!

-

hey everyone. firstly i want to thank the members that helped me figure out the issue with their advice. i have found that it it was the grinding wheel in the end that is causing the reaction to my skin, in combination with the heat that the sparks produce. i get the itchiness only when hot sparks come in contact with my left hand, which in general has developed a higher sensitivity than my right hand, exactly where the skin is softer. this will be countered in the future by wearing a long shirt while grinding so as to cut off the source of the problem. Frosty your advice has helped a lot since i have almost the same sensitivities as well. i too get itchy after a hair cut and i am in general an itchy person, (beard, head). maybe it is something in the bondage of the stones and if i could by any means find out what it is maybe i could find some other brand stones which do not contain that chemical so as to solve the problem.. is there any way i can test this? of course i will avoid it now by wearing long sleeves but i would prefer it if in some way i know what is causing the problem so as to buy something else, because believe me long sleeves is almost torture with the heat we have here. today for example is 32 celcious..

-

My Israel Trip To Learn From Uri Hofi

santisandreas replied to firebug's topic in Blacksmithing, General Discussion

thanks Glenn. i just did. i hope they can provide the info needed.. -

My Israel Trip To Learn From Uri Hofi

santisandreas replied to firebug's topic in Blacksmithing, General Discussion

hello there. nice story. because i am from Cyprus and Israel is right next door from us i was thinking of going for a course to Uri Hofi this summer. but unfortunately i cannot find the means to contact him. some of his previous students who own a forge that teaches the same techniques in France have told me that it is possible to go because there are still courses in Israel but haven;t provided the means to contact him. How did you reach him? can you direct me to a site or something? i would really appreciate it.. thanks in advance -

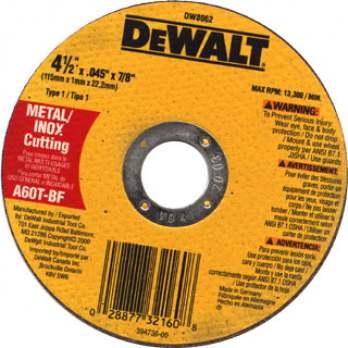

update: i think it is the angle grinder disks. i had a small reaction to them today.. my hand has some red spots and is a bit itchy but not so much as last time.. and it happened while using the dewalt cut off disk. yellow one. but i noticed that it gets itchy when the sparks touch another surface and then get back on my hand. left one mostly. i will resume testing and update soon enough. images of the grinding and cutoff disks..

-

hey thanks again. i am not 100% that its the the stone wheels but i think its them because they where low quality as well. i think Chinese origin. i will take a picture of the wheel tomorrow and the grinding disk maybe someone can tell me what they have in them. with the Bosch wheels that were on the bench grinder originally i had no problem. but i will do a test tomorrow and let you know of my findings. it might be the epoxy as well. not really sure though. get back to you shortly. sorry for the late response.

-

thanks a lot frosty. you are very accurate. yes my guess is a chemical reaction as well. i am sure it is not the metal because if it was, it would have happened very often since i am always using steel. i think it is most probably something from the grinding disk or the stone but i am not sure which one. when it happens again i will be 100% sure which one is it and then post it here to figure out what are the substances of that particular disk or stone and then try to use something else. I am now 80% sure that it is not the angle grinder disk because now that i stopped using the bench grinder the itchy effect has stopped and yesterday i was grinding with the angle grinder and nothing happened so i am guessing that it is from the new stone that i bought recently. i will do another test today and get back to you soon.

-

This is some good responds. Thanks. I am very aware of the dangers explained in the last few posts and i am very cautious when using a grinder. I am generally a cautious person as i consider anything i do twice before i do it especially when it has to do with extremely dangerous equipment such as the angle grinder. Once it got stuck somewhere while cutting and just slided out of my hands but thankfully it went towards the opposite direction rather than towards me. Since then i have been very cautious with it and go quite slow when cutting so it doesn't happen again. Added to that i generally stay out of the way of the sparks and handle the grinder with my attention to the maximum. But in regard of your question Glenn, no i wasn't wearing a long sleeve shirt when it happened and the sparks went onto my hand so it felt like i had small fragments not seen by the eye, attached to my skin so it got all red and a bit itchy. But my question was if i might have some sort of allergy to it, or to any of the substances in the stone wheel. Or is it a common thing if one is grinding while the fragments come in contact with the skin? Does it happen to you as well if you are wearing short while grinding. One thing is for certain though. from now on i will be wearing a cotton shirt and when grinding i will roll the sleeves down as well as wear a leather apron so the shirt does not catch fire.

-

Hello everyone. i have another related issue with the angle grinder lately so instead of posting a new topic i decided to post it here. when i work on grinding with the angle grinder and the bench grinder with the stones i get a skin rush on my left hand where their is no hair. two days ago i was grinding and my hand started to get a bit itchy and all red. at first i thought it was an allergy or something because it happened in the past but in a smaller degree and was gone after a shower. now its worse and its the third day today while i still feel it. but it started to go away. did anyone have anything similar in the past? could i be allergic to small shards of metal? because i don't have anything else while working so its kind of strange..

-

i thought that if you bolt a taper die it would kick back the stock towards my body and maybe cause harm, so i was trying to think of a way if one can forge it with the flat dies.. but thanks for the advice. are you sure it is not dangerous to give an angle to the bottom die? i think it is safer to do the pinch die probably, so as to eliminate the kick back which will make it easier as well on the hands as i will be making a lot of them as well.

-

hey everyone. since you have some more experience on the power hammer i want to ask you a question, especially timothy who has started this post. i got an order the other day to forge a lot of tapers for a fence which is 400 m long. and the welder who applied for the job want the tapers done by a blacksmith so that he doesn't need to grind a 25 mm steel rod into a short taper. but before i can accept the job i need to make sure that its doable. due to the large quantity and the size of the 25 mm square stock it will be too difficult to forge them by hand. is it possible that this taper can be forged on the power hammer? i am not familiar with the techniques of a power hammer and neither do i own one. but i will meet with a fellow blacksmith in Nicosia that owns one and probably do the job with him. see the taper below which was forged by hand. in particular my question is if it possible to forge such a steep taper on a pair of flat dies. I have seen in the past some tapers forged under the power hammer but they were too long compared to what i want to do.

-

here in Cyprus it is very hot and dry to semi humid sometimes! i think that wool is a bit too much but i will look for a cotton shirt and a bib overall i guess which i think will be great! but i will need both a leather and a jean style bib. those will be great i guess for general purpose smithing, and then for the grinding or welding i might add a leather apron. thanks for your suggestions Mr Charles and Thomas!

-

thanks for everything! i will try some 100% cotton shirts and t shirts for a while and see how that goes and i will keep searching for some clothing with an external layer of leather attached to it. maybe i will find something.. but i think that wool is too hot for cyprus! thanks though for the great advice!

-

thanks a lot. that was very educational.. i will go get some cotton shirts to try them and continue wearing my pants! thanks again..

-

hello again, just a question. does anyone want to speculate on how much an item like this should be charged? roughly... just to get an idea on pricing from more experienced people.. thanks in advance.. i will post some other items as well along the way from the same job.

-

hello everyone, i have another thought about clothing while in the forge. Recently i found some anti fire clothes that are bought frequently for the welding industry which are specialty made by Panoply so that they resist fire from sparks while welding or grinding. the leather apron is quite uncomfortable to wear because it is heavy in the neck and hot while wearing so i thought to buy trousers and a long shirt with this fabric so as to reduce the weight on my neck and the heat from wearing multiple layers of clothing, considering that i live in Cyprus where the summers are average 35-38° Celsius and sometimes even 40. the only problem is that they had the trousers available and i bought them immediately but they didn't have the shirt and after waiting for a month for it to arrive i have decided to look elsewhere. does anyone know of any place where i can purchase online such clothing that is related to blacksmithing? did anyone ever use anti fire clothing before besides the leather apron? if i find anything on my research i will post it here as a future reference for others who might feel more comfortable with such clothing rather that to have to wear an apron all the time! by the way the trousers work great while smithing and dont have a single hole on them after one month's use..