-

Posts

68 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Manitoba, Canada

-

Interests

Self-sustainment skills, bladesmithing and general fabrication.

Recent Profile Visitors

-

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

I thought this was supposed to be a resource for people to ASK questions and seek answers from there in the space? If not, then why are any of us here? I recognize experience, and was simply stating mine, and asking questions so as to better understand. Everyone was a beginner once... and very often, the problems I find with forums like this, is that there is co flicting information, Everyone is convinced that THEIR way is the right way, and instead of trying to explain something it devolves into an argument... Really makes it discouraging for any new makers to want to engage. Just my opinion, I take no offense at anyone else. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

I may have done past tempers at too high a heat... I think I had tried at lower temps and hadn't gotten the color draw I wanted, so went hotter. That is on past attempts though. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

I meant that, at the proper temper temperatures, if I put it in for hours, I would move well past the colour spectrum required, and would wind up with a soft blade. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

If I were to temper this back fir a couple hours, it would have no hardness whatsoever.... I generally find, Mayne an hour MAX for the blades I've made in the past. Why would you "retemper" a second time? -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

Fair enough, ad I didn't mean to put any words in your mouth, apologies for that. I see your point 100%, but, in the learning process, I'm willing to take the risks for the sake of learning. Cannot learn without mistakes. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

Wasn't that much of a waste, frosty, but I see your point. Was made with some free coil spring, so no waste there... and, I don't consider anything a failure... simply a learning opportunity. As far as heat treat on this, I have done the same several times on a few different blades/tools with recommendation from another Smith. Able to get this one shaving sharp, so it is at least able to take an edge. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

I hear you. I run a charcoal forge too, so reaching, and maintaining a proper temperature gets a bit finicky. But, it is all a learning process. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

thanks, this will be my first slab-scale knife. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

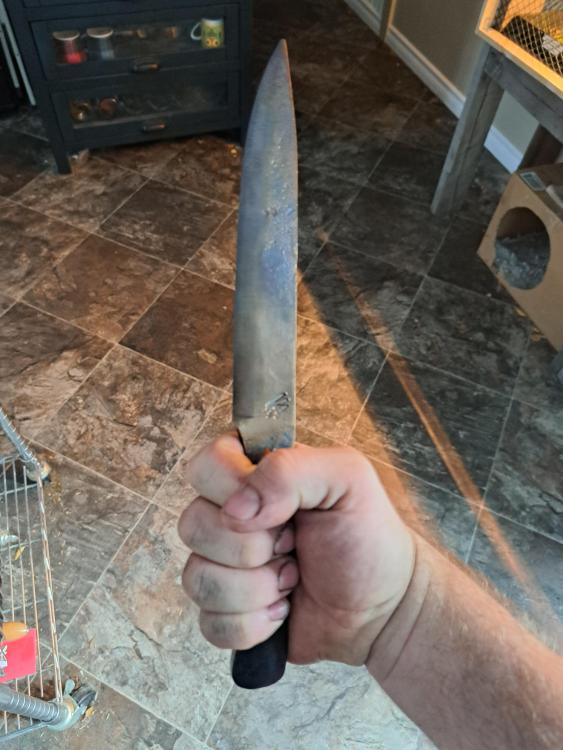

Banged out a blade this weekend. Got heat treat done, but I was second guessing myself, and ended up doing it a couple of times. I'm still trying to figure out what best temper/heat treat is for knives from this material for best edge retention and durability. Next step is adding handle and finishing. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

That's a slick lookin sword. I love the hilt design. Thanks! I'm really happy with how the guard turned out. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

Partly what the metal did for me, partly what my wife wanted in the design. It is sort of a mix of a cutlass and a falchion. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished all but for sharpening. Next step is the scabbard. I learned a lot of things in this build that I will apply next time. There are some quirks, and issues with this one, but for the person it is going to l, it will do, and they like it. Final weight, 1lb 12oz. Overall length, 26", blade length, 19 inches -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

"Very nice, WR. It’s got a lot of character." Thanks JHCC. I'm pretty happy with it fir a first ever sword. Learned/tried lots of new skills on this one. -

What did you do in the shop today?

Wandering_R0gue replied to Mark Ling's topic in Blacksmithing, General Discussion

Continued working on my sword project. Today was Hilt day: Made the guard, pommel, and fitted the grip. Still have to do all the final finishes and fitments. Will likely do a cold-blue or patina finish on guard and pommel, and a red leather wrap on the handle. Will also have to make a scabbard. -

diy Necessity and Invention

Wandering_R0gue replied to Wandering_R0gue's topic in Finish and Polish for Knives

True, but, for now, It is what I have.