FatBadger

Members-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by FatBadger

-

What did you do in the shop today?

FatBadger replied to Mark Ling's topic in Blacksmithing, General Discussion

You can't pretend that smile TW. -

What did you do in the shop today?

FatBadger replied to Mark Ling's topic in Blacksmithing, General Discussion

It's been a very busy couple days here. I was very fortunate enough to have my family's help through the process. My Uncle who is the smith who's teaching me (I've read the mistakes newbies make section) (I'm not a very good apprentice) made himself, my cousin, and his boy available. Mostly my cousin was here with me while we set up the new shop upgrades. As I said been busy busy, I'm ready to get back to work...but we did get a good forge day in today. But it was a good day. -

We converted it to run 2x82 and 2x72. We shortened the 1 1/2 bar and bought a couple of others for the other attachments. The bearing shaft was the pain to get just right for the extra wheel attachments. So we sent it out to a local machine shop and got a couple spares. I ordered off amazon and they were very comparable in price for aluminum oxide.

-

I bought a vevor 2x82 variable speed grinder with forward and reverse for apprx. 1300 delivered. We've done plenty of Mod's to it and it seems like, if you can weld it might be in the 750 range plus metal(with vevor parts)(glad I ordered by Amazon) .

-

What did you do in the shop today?

FatBadger replied to Mark Ling's topic in Blacksmithing, General Discussion

Beware of the man with 47 hammers, cause he probably knows how to use them. -

This gives me plenty to start with. I'll have a look at the other thread, thanks.

-

What did you do in the shop today?

FatBadger replied to Mark Ling's topic in Blacksmithing, General Discussion

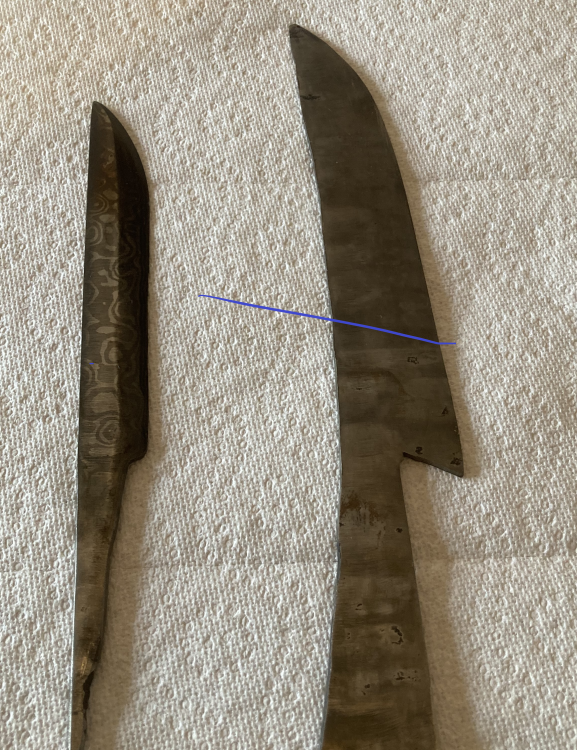

Thank you all for the positive feedback. We got started fairly early for Sunday. Then we moved to some San Mia. But we used a cutoff from a box of junk from (Vegas Forge) 5 lb. box for our core. We need to fold next weekend and stack with 15N20 in the middle for a little pop. (left the cutoff - right at San Mia 1095 mix) And tongs and fat shop dogs. Wow that's an Awesome spatula. -

I'll try to catch up, thanks.

-

What did you cut the primary hole with, if I may?

-

What did you do in the shop today?

FatBadger replied to Mark Ling's topic in Blacksmithing, General Discussion

I Started the morning with some pritchel holds. Me and my cousin, who was down this way got a good start at 9 or so. We moved on to a 7 layer 15N20 and 1084 stack and squeezed that for a bit. Then... He had a go at a piece of 40 layer, as a arrow head. Then fitted a couple quarters to close out. -

It seems I have 2 grill-smoker projects going. Here's the first with a few measurements, you've seen the second. If you need anything else just let me know.

-

Devo chiedere, materiale, metodo?

-

Il tuo rendering è fantastico, non vedo l'ora di vederlo completato. Frank

-

Are you talking about Canister Damascus or geology minerals? Smelting..

-

I grabbed some snowmobile leaf spring and replaced what was a impromptu spring for my peter wright it works really well.

-

Looks like my ladies are 1-2-16 hundred weight (184 lbs) and 1-0-27 hundred weight (139). I'm going have fun putting them in new dancing dresses and fitting stands.

-

-

Pat Are you comparing Aluminum Oxide Metal Sanding Belts against maybe Ceramic Sanding Belts? They would be almost double according to what I've bought.

-

What did you do in the shop today?

FatBadger replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Atlas power hammer

FatBadger replied to onetreeforge's topic in Power Hammers, Treadle Hammers, Olivers

Can't wait to see her all cleaned up. -

Power hammer foundation follow-along

FatBadger replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Looks awesome to me mate. Passion and drive are 3/4 of any project as far as I can tell. But I'm more of a rookie than you. So I guess we'll have to try and power thru our shortcomings. I'll watch for more updates to see how you turn up. Good Luck, -

Prestacked Ready to Forge Damascus - Help

FatBadger replied to Pat Masterson's topic in Blacksmithing, General Discussion

Alec Steel shop has stacked billets, but It seems there out of stock. -

Finally! New to me anvil

FatBadger replied to justknapping's topic in Anvils, Swage Blocks, and Mandrels

She's definitely a looker, good on you for putting her back in service. -

Just a little greenhorn poking thru my hat...lol

-