-

Posts

97 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Vasa, Finland

-

Interests

Blacksmithing. Wood work. Gym. Violin.

Recent Profile Visitors

-

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

After one day of medication in the hospital it started getting worse. The seizures started coming every second hour. That was scary. Then they changed meds and the seizures completely went away. Now it's been 8 days of new medication without a single seizure. That's great. She will have to take medicine three times a day for 2 years to keep them away. After that she should have grown out of it. Lucky for us we don't have to pay anything for the hospital. The state has a low limit for what patients have to pay and for that we have an insurance. The meds we have to buy each month. I think they will cost about 18 €/month. Thanks for the kind words and the prayers! Freja is back to normal! She's testing her voice now and also just learned to roll over. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Thanks for asking! I'm sorry to say she started suffering epileptic seizures this week. Her body froze in place for a minute at a time. She's in the hospital now. They took her in right away and are doing tests now and giving medicine, so she's drowsy now. Before this she was doing so well! Practicing her gripping and biting and talking. I had these same seizures when I was a baby. In general, they should go away with meds. Mad Max is a compliment, thanks Frosty! -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Today we backfilled and compacted the hole. I ripped out the black pipe. I hope you are happy now, Frosty! After that there was some time left so we started on the floor. Suddenly the floor was gone also. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

That's very reasonably. One could perhaps think of it as the ground here consist of some % water! So if I remove 10 % water then there is less ground and the buildings sink. I'll remove it. Lack of experience, planning, some laziness, I guess. I'll get to it in the next few days. Last weekend I sawed the floor in pieces. We'll leave it the floor in place until we have backfilled the hole and then we'll start lifting out the pieces with the tractor. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

That's my dad in the pictures above. On the picture where the form has lifted one can see I put some pieces of sheet steel between the platform frame and the 2x4s. Small details. I thought maybe the boards would sink into the frame and I would have no control of what I'm doing otherwise. If I were to do this again I would do it differently. The angle irons would be welded some 50 mm higher up on the frame so they wouldn't be in the way for finishing the concrete. Same with the wooden boards above the anvil box. To handle a 500 kg load on top of the anvil box I might have braced the form differently. Maybe two diagonal braces from the top middle of the sides down to the bottom corners of the sides. I removed the form the following day. The block was warm from the chemical reaction. Very cool. When I removed the anvil box it steamed from under it. I put a thermometer there and it read 33 °C ! My dad suggested we'd cover the anvil hole box in plastic so it would come off easily. I wasn't keen on the idea but I thought let's try it. The plastic fused to the concrete. Don't know what to think of that. I watered the block some, one time the day after the pour, then again 3 days later. Yeah, I realized later that I should have watered it every few hours for the first few days. But I did go back a few times more to water it. I didn't realize how much watering it needs. I read it becomes about 50 % stronger from proper watering. But then today 2 weeks later it stood in 30 cm water, however. It has been raining. We pumped it out. The block turned out fine! It became quite uneven around the anvil hole due to the boards, but I can grind that flat. The angle irons also left marks. All in all I'm happy with it. This is as far as I can go at the moment. Now I'll saw the floor in pieces and start working on a new one. I've decided to leave the black drainage well pipe in place and lengthen it up to floor level. But I'm not sure how to think about that. When the floor is done and the hole is all filled in, who cares if there's water down there? The concrete doesn't. I think I'll run a small diameter pipe from the drainage well to a floor drain. From there it would then flow onwards and out. So if I want to I can leave the pump in the well, pump water up into the small pipe, which goes to the drain, and then it would flow out by itself. The other alternative is to rip out the drainage well and do nothing. It feels right to pump out water, but perhaps it's futile. The weight of the block is 6,7 metric tons. In my opinion it is 1 ton too much. But I wanted and was told to put a lot of concrete under the anvil. I was told 1000 mm under the anvil, I put 560 mm. I wanted a lot of weight in front of the hammer, so the anvil would stand in the center of mass. I think this resists the block tilting, if corner pipes would start wandering. So that leaves the sides as spots to save on concrete. I could have shaved off 100 mm per side of the block. But it felt proportional like this. Who knows. Perhaps a lot of mass absorbs the impact of the hammering and doesn't transfer it so directly to the piles. Helps keep the piles from wandering? Proper professional piles would have a hardened solid steel tip, that would dig a small cavity in bedrock and make it stay put. I guess this is just mental gymnastics! It will be fine. If I start blacksmithing so hard that I ever get a problem with this, I'll be happy. Thanks for all the help everybody! I'll post some pictures of the floor here also later because why not. I can't say when I'll be installing the hammer. I need to renovate a house first... -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Then there was the day of the pour. The company called and asked if they could come sooner than agreed. I said no, then I got a text message: "We're on our way!" 45 minutes too early. Hehe. It was fine. These concrete trucks are enormous! We started using the vibrator as soon as there was some 20 cm concrete in the form. We didn't use it nonstop, but short bursts throughout the pour to make the concrete flow everywhere. The elevated platform kept its concrete without problem. The concrete didn't sink down in it. Then at some point we noticed that the box for the anvil hole started lifting up!!! The weight wasn't enough! We hurried and carried an anvil on top and two batteries. Fortunately the box was screwed in place!!! That's probably what stopped it from rising further. Talking to Frosty, I was told 150 lb weight per cubic foot displaced concrete is a good rule of thumb. Following that, I would have needed 500 kg. About the same as the amount of concrete that would fit in that same hole. I had 210 kg. Well, I was lucky. The end result was only about 8 mm difference in hole depth. I can compensate that with the wood I'll place under the anvil. The concrete I wanted to use would have been SR-concrete, sulphur resistant. Because as the ground here is an old seabed and full of dead organic matter it's also acidic. I think that's why, at least. Acids eat steel and concrete. When they make bridge footings around here they do piledriving with stainless steel pipes. I used regular mild steel pipes. They didn't have SR-concrete in store right now but they had "bridge construction concrete" which was K45 xc4 xf2. 4 classes higher strength than regular, high water tolerance and some acid tolerance. I was happy with that. The pipes rust some 1 mm per 20 years, or was it 50? So it'll stand 120 years. Good enough. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

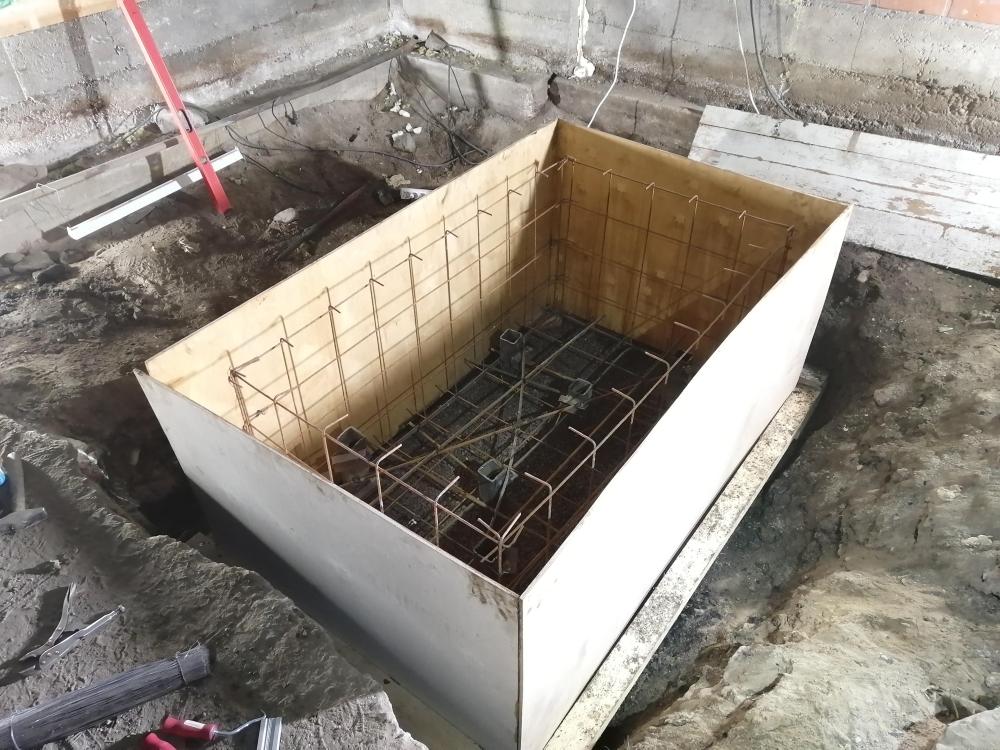

My apologies for not sharing the progress sooner. When I got this done I relaxed and started thinking about all the other stuff I need to do. For example, rip out the concrete floor in this workshop so I can put polystyrene under, and pour a new good floor with floor heating. Also I need to renovate a house... In the pictures below you can see the platform with reinforcements. I welded the rebar to the sheet steel so all of it became very rigid. I took measures to avoid the bolt holes. Next picture is the form with mesh steel near the top surface and sides. I welded threaded rods to some rebar and stuck that out of the form, past the 2x4s into channel iron, to brace the sides. We welded them on the spot. Third picture shows the box for the anvil hole. I made it from plywood with wood braces inside. It was nailed together from the outside so it all comes loose from the inside with a crowbar. The bottom plywood sheet of the box was put inside of the standing sheets, so as not to get jammed in the concrete. Hundreds of small details with all of this. I hung the platform on top of the form by welding 50x50x5 mm angle iron to it with 3 thick weld beads. I figured the form would be strong enough to hold the platform with a bunch of weight on top. I put about 2 screws from inside the plywood out into the 2x4s around the box. So they work together and are rigid. The weight on top is also the reason I put the topmost 2x4s standing on edge. Just improvising. This could be done in many ways. Fourth picture shows the box in place. I simply screwed boards to the 2x4s sticking up out of the box and lowered it in place. I put some extra 2x4s there to share the load of the weight I put on top. I also screwed the middle boards to a board that was fastened vertically to the form. So the anvil box can not float up without lifting all of the form. At first I put about 100 kg weight on top. Then I added more so the total weight was 210 kg. I figured it would be enough as the volume of the anvil hole is about 210 liters, which if it were water would weigh 210 kg. Turned out it wasn't enough. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Time flies. Our daughter got her name one weekend so we celebrated that. She got the name Freja, pronounced Freya with a rolling R. Then the next weekend I exchanged the 50 year old dried and cracked boards before the heat pump could be installed. I weighed all options and this was an easy install and the price fit the budget. It cost 2400 € with the install. I'll just have to cover it up if I do some REALLY dusty work, and turn it off when I do blacksmithing. Because it circulates the air in the room when it heats it up. It does have a filter, though, which needs to be rinsed every now and then. I was told the U-beams I welded in place were too smooth so the concrete wouldn't grip onto them. And large cracks could start growing along the beams. So I cut them off and welded 12 mm rebar to connect the pipes. Then a mesh on top on top of those. On top of that two lengthwise rebar, two widthwise and two in an X. The X is some 100 mm higher up. I want these in place so that the concrete under the anvil for sure won't crack. Then I put mesh along the sides and I will put some near the top surface later. The form is not done, obviously. I will put 2x4s on a few levels around the 9 mm plywood. Then I'm thinking I'll reuse the U-beams outside the form. I'm going to stick threaded rods out of the form past the 2x4s. Outside the 2x4s I'll put U-beams vertically and pass the rod through them, so the U-beams keep all of the 2x4s from bending and splintering. Today I welded up 3 mm sheet steel for the elevated "platform" for the hammer. I bought these pieces ready-made. Which saved me a lot of headache. Slowly but surely it's all coming together. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

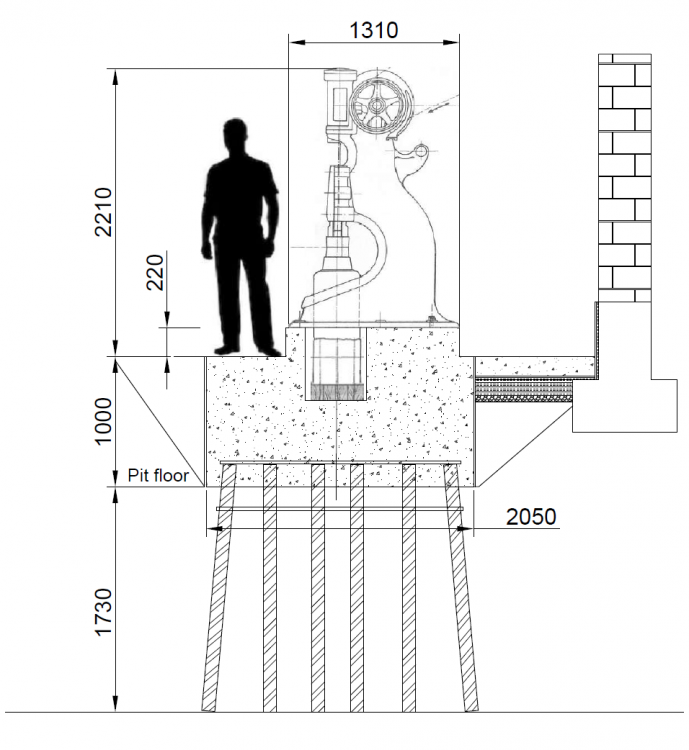

Next up was steel reinforcements. I thought about using layers of mesh steel throughout, but Frosty reminded me to think like an engineer and put beams to resist the bending moments. The lengthwise beams resist bending in the lengthwise direction, the widthwise beams do the same for the width direction. Had these beams been close together resembling a cross, then the weak bending plane had been along the diagonals, that's what the crossways laid U-beams are there to resist. In practice I put the beams so spread out that there were no weak bending planes. The U-beams are also 3 inches higher up than the rest. Not much, but room for some concrete in-between. Too much iron in one spot weakens the block. What bending, you might ask. Well the hammer is a 2 piece so the anvil will be in a pit. So the weakest place of the concrete is right under the anvil. What if water seeps up into the block and weakens it, and the hammer blows out the bottom of the pit? Most likely it would never break, but who knows. I feel better about it this way. I found scrap 30x40 mm U-beams in the backyard which is perfect for reinforcement in the concrete block. I welded them to the piles using a stick welder, Finnish Kemppi Tylarc with long cables. I had pumped out the water previously. I was still standing in some water but I was wearing rubber boots, I was not on my knees or otherwise wet. I welded the rebar to the piles well because I want more bearing surface for the concrete than the tops of the piles. I wanted many places for the concrete to grab onto. Remember, there's no bearing force for the concrete from underneath. It's soft silt mud. Basically the concrete block will be floating on top of water, standing on the piles which stand on bedrock. Today I put gravel in the pit on top of the filter cloth. It's impossible to get good compaction of the gravel when there's mud underneath but I went around the form with a 2x4 and compacted it as best as I could. I put the gravel there to get the pit floor to the level I want for the form. Concrete doesn't care, but my form needs to be at shop floor level. And the form will stand more stable on some gravel. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

I do wonder about anchoring the hammer. If I were to cast threaded plates inside the foundation with pipes going up to the surface, and insert threaded rods after the hammer is in place, then I would have to do that now. The other alternative is to drill the concrete after the hammer is in place and epoxy the bolts in place. Back in the days they used worse steel, perhaps that's why they wanted the longer bolts. Long bolts that can stretch. Short bolts don't stretch much, they break. That's the only reason I can think of. But also a bouncing machine perhaps could do better with "stretchy" bolts? Hard to say. Long bolts are probably better but they're also a lot of extra work and I'm just a hobbyist. I was told by Roger Lund, the industrial blacksmith, that the hammer should stand on concrete. It should stand on a few bearing points 30 mm in the air, and then be grouted in place. So there's no bouncy material under it at all. Then the bolts don't break. The anvil should move instead. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Since I last posted I insulated the walls and ceiling and I added a vapor barrier. I was worried the pit would freeze up. The greenhouse effect, ground heat and sort of airtightness will keep the shop a few degrees warmer than outside. I'm thinking of installing a single gypsum wall sheet so I can order a heat pump and have it installed it in its final place right away. Talking to Frosty, he suggested making a depth map by hammering an iron rod down until it hits bedrock. I did so and I hit bedrock 1.5 meters down. I found 1.1 meter long pipes on an auction site which I welded end-to-end, giving me 2,2 meter long piles. 80x80x6 mm. I made a pile-locating jig which I'm standing on in the picture. It was a good idea, but after looking at the depth map I shifted the piles around to hit the higher spots. Just yesterday I got all the piles driven down. It went very easily with the tractor front-end loader and the bucket. We used it as a press first and a hammer at the end. The bucket weighs, perhaps 200 kg? One of the outer piles kept going down, slowly with a lot of force. I don't know if it started skidding on a slope or what it is. I guess I'll either hammer it down more or pull it up again and push it down somewhere else using the tractor. The next step is to weld angle irons and rebar between the piles to provide lateral support for when the piles start walking. It will also spread the load of the concrete between the piles and will give more bearing surface for the concrete to avoid point-loading. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

The baby came knocking and so all work stopped for 2 weeks A super healthy little girl with an inch long brown hair. Grows very quickly too! She's put on 2 pounds already. How amazing babies are! All in all the hospital cost was 250 € for 2 days stay, food included. Not bad! The mother will get 9 months paid leave from the state, and that's a good thing because this baby is a full time job! I found some time now and the foundation work progressed as shown below. I wanted to get rid of the water so I pumped it out and then installed a temporary drainage system. Temporary as in the black pipe which houses the pump will be removed later when all is done. The white pipe can stay. I built a wooden form to keep the walls from caving in. There's plenty of empty room around it, yeah, but at the brick wall we filled soil back behind it, more than it seems from the photo, so the dirt under the brick wall will stay put, at least. I put a white filter cloth on the pit floor so I can fill gravel and get an even and stable floor. Dad cut it a bit too long. But before the gravel I will have to drive down piles. I'm looking at 80x80x6 mm square tube. The professional pile driver said 90 mm round should be enough, and 80x80 has more steel in it so it should be good. There's a big difference between a 50 pounder and a 165 pounder. Then there's the thickness of the slab, soil properties, etc. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

You're welcome to visit! The iron rod was a smooth iron bar, 16 mm. I went out again and stuck it down and bashed it with a hammer. It rebounds hard like it's bedrock. The depth of refusal is 170 cm below the pit floor. I can push a 50 mm pipe perhaps two feet until it starts getting tough. Haven't tried hammering on a pipe yet. The mud is such that one doesn't sink down more than a couple centimeters. Do you mean I-beam is better than a pipe? I don't have more than 2 piles worth of steel lying at home. I will have to source more somehow. I think it would be smart to put as many piles as practical. For example if one would catastrophically wander off. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Please don't comment on this thread anymore. -

Power hammer foundation follow-along

Jarntagforge replied to Jarntagforge's topic in Power Hammers, Treadle Hammers, Olivers

Do you mean at the surface of the pit? Because I can't get rocks down to the bottom. It's two meters of mud.