-

Posts

226 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Red Shed Forge

-

It reads like you are saying your carport work WAS shoddy and your recollection of it was implying mine was also shoddy. I responded so harshly because I felt I was being checked for naivete of not only a risk, but of my own impression of my work. When you have given direct advice or made recommendations to me recently, I truly appreciated it and looked into making it happen. I do not ask that you stop giving me or anyone else your 2 cents. In this instance I felt wronged and driven to reply as such.

-

There's the buzzkill I felt was on its way! You're right, it's foolish to trust a system of community members intent on helping each other. It's far better to go about assuming the worst will happen and friends and neighbors will abandon all integrity of choices made; will point blame away from themselves and acknowledge no involvement in the matter. I'm sorry you're jaded by a 'friend' who sold you down the river. I do appreciate your concern and subsequent need to impart your experience, but I'm interested in what you find shoddy about this work? When Jesse came to pick it up, he put it to his test. He stomped on it, got up on it with both feet and all his weight and bounced up and down a few times. He got down, looked at me and remarked that it had to be the strongest rung on the ladder now. He then worked on it all day and texted me another thank you for my work. Of course insurance is important. I'm fortunate to have it. But when I didn't have it, I was still doing work some might consider risky in the same manner. But I only ever delivered on the work if I thought the final product was up to my standards and the standards of the client. To discourage neighborly aid with the assumption that if they get the chance they will do you dirty, is to encourage community mistrust and is inherently divisive. Cautious, yes. And if you can afford it, get it. But I advocate for confidence in this situation. Confidence in my work to hold up, and confidence in my hardworking neighbor's integrity.

-

Shortly before leaving the office Friday, I get a text from the foremost hired hand of Bolingbrook's Colonial Village, Jesse. It's two pictures of a ladder with its final rung lopped in half, and a plea for help. He asked if I could weld it back together tonight as he needs it for a big job in the morning. Aside from his drywall work and snowplow route, Jesse employs a handful of our neighbors in his seasonal gutter-cleaning business and, of course, 'tis the season! The towering maples, birches and Siberian elms (oh, the elms; they shed their limbs before their leaves!) fill blocks and blocks of uncovered gutters with their audacious deciduous behavior. The gutters have thawed and drained, leaving behind the organic muck. Be not careful to maintain your gulping culverts and with time a maple will be stretching its trunk above your tall colonial roof in its youth! Our seasonal savior Jesse was in a pinch and I knew I had to help. Those 36 footers are dernnear $500 on the cheap! I explain to Jesse that my arc welder would surely blow holes in that costly aluminum frame, but I can certainly replace the wrecked rung with my fabricationry, or as I truly hoped it would be, with my certified blackmithery. When he arrived, I presented him with my idea of feeding a 1" piece of conduit through both side holes of the ladder legs, cutting a 1 1/2" line down the center of each end of the conduit, splaying the separated ends left and right and then bolting them through the legs. Despite the conduit being very similar in thickness and diameter to the original rungs, Jesse wouldn't have it. He explains that he wants to be able to step heavy and hard on his first step in his ascent, that he must not encounter this issue again. "Do you have something stronger?" With that, I lead him by light of smartphone to the oxidizing hoard of Red Shed Forge just waiting for warmth. With a smile and air of urgency, he left the selection to my imagination. And so I went to work. A long handle protruding up from the carcass of a butchered air compressor caught my eye. A 1/4" round bar bent to a 24" rectangle. The angle grinder threw bright sparks which quickly frayed and burst on end; it moved under hammer not so quickly, not so slowly. To commence in my smithness; to commence with the knowledge and feeling that this patron of handiworks to the villagers needs my assistance, is to commence with inspired and confident vigor. A simple ladder rung repair becomes a reinforcer of an -- unorthodox venture. A seemingly antiquated skillset remains, steadfast, a purveyor of neighborhood repairs. My 3-hour Process: 2 round bars forge welded side-by-side on each end Ends forged out to rounded tabs Rounded tabs drifted, hamburger style, to avoid splitting the weld Tabs twisted in vise to proper orientation 1 tab bent at an angle Ladder end is dragged up onto heal of the anvil Cold end is fed through bottom hole in ladder leg, while straight, heated end is fed under and through the top leg With rung placed against the side of the heal, the heated end is hammered and bent down onto the side of the leg As the rung cools, it grips tighter Holes are drilled through the ladder legs, bolts are inserted and tightened Finished with rust-preventive gray spray paint.

-

No worries about the pictures. Makes sense. And I think I would prefer the route you took with the drift for opening the slot, as I see a small potential for the outer bosses to bow either in or out with the upsetting approach. The drift also gives you the exact width you are going for. And even if you somehow marred the inside of the boss, you could use it as a flatter as you mentioned earlier in the process.

-

There 'ya go. That would be a cool build. I even make charcoal for neighbors to grill with sometimes. I wouldn't use pallets in the case of the smoker though haha.

-

There's no building involved in a can-in-barrel retort. I bought a 55 gallon barrel on FB marketplace for $20 and picked up an empty metal trashcan someone had just sitting at their curb! (just kidding I bought that too). After I started telling friends and family that I make charcoal as fuel, many were happy to just give me their extra timber, especially in the summer when everyone is trimming and removing trees. A 30 gallon trash can produces about 15-20lbs of charcoal, depending on the type of wood used, in my experience. For tinder, I drive around business parks/complexes looking for pallets and other scrap wood if my usual hook-up has none at the time. Most villages don't like you burning "construction material" and the desiccation aspect of pyrolysis causes a good deal of smoke at one point, so I choose to char at night under cover of the "dark" suburban sky. Never had a problem with neighbors as bonfires are a common backyard occurrence around here. I should add, when using pallets, you will be dealing with the MANY nails/staples/screws that hold the pallets together, so a sifting and magnetic-collection process is necessary to avoid issues in the firepot.

-

Rockstar.esq, That process certainly does seem more complicated than the half-lap. Also sounds like you've got it down! I've seen riveted box joint tongs but never seen them forged out, I'll look into some videos. If you have a picture of yours that would be cool to see after the nice visual you gave of the process.

-

Thank you for sharing that video, John. Very helpful. I actually made mine based on a Joey van der Steeg video where he used 3/4" round spring steel. And thank you for mentioning the bosses as I am wary of mine for the reason you mention; they are slightly more than half the thickness of those in that video. I'll keep this in mind when approaching my next pair. Hopefully they don't give when I use them on my current scrolls.

-

Well now I want some better wrenches too! Lol. I've got some sections of 7/8" round stock that I believe was used as canopy tent stakes that might work..? It was painted yellow at one point. IIRC, they have some crowning at one end from what I assume is damage from hammer blows. Too soft?

-

I posted last year in September when it "Followed Me Home", and a response I got advised that it was sucker rod: However, my FIL who gave it to me, acquired it from a deceased neighbor who in life had no known (to my FIL) connection to well pumping. He was an electrician and collector of much scrap steel in south-western Kentucky, so it is difficult to pinpoint from where it originated exactly. It certainly sparks and forges like HC steel (in my limited experience), so maybe it is related to an electrician's vocation, rather than sucker rod, if most is MC like you say. I do have a small, poorly forged scrolling wrench and hardy bick to assist in tweaking the scrolls as well. I made the tines on these tongs 2 1/2" long with the thought that their length would be helpful on the wide stock. Maybe it's just me, but I also did not find it too difficult to move with a smaller pair of needle-nose pliers, so I assumed mine would do an even better job. We will see.

-

I needed a pair of scrolling tongs for some desk legs I have been working on. I have some 3/16" x 2" flat stock scrolls that will be attached to the legs; my hope is that these tongs will help me refine the imperfect scrolls. These are the third pair of tongs I have ever forged. I have yet to test them and at face value, they could certainly use some improvements in a few areas, but they feel sturdy and comfortable in my hand. I learned a lot along the way in regards to number of heats used, hammer techniques and control, and overall confidence in my abilities. They are forged from 5/8" high carbon sucker rod. They are 11 1/2" from the tine tips to bottom of the reins. The reins span 3" in width. I drew one of the reins a bit thinner than the other and my rivet could be bulkier; I plan to improve on these two aspects on my next tong forge.

-

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Chimaera, that sounds awful! Man, I cringe at the thought! This weekend was spent with the in-laws who visited from Kentucky. Tim and I worked on a desk for my wife who spends most of her work week at home now. Tim is a better carpenter than I am blacksmith, so he helped me build a very nice frame and desktop with temporary 2x4 legs. He was also my temp-apprentice at the smithy for the weekend, assisting me in measurements, leveling ("he's level on a level"), and multiple snow quenches between working pieces. Despite using a scroll jig, I still need to tweak my scrolls with a fork and bick to achieve a better visual of uniformity on the legs. We also attempted to hot-collar the scrolls to the legs, but I certainly need more practice on smaller stock before I continue with that. I followed Francis Whitaker's instructions in "The Blacksmith's Cookbook: Recipes in Iron" in my attempt; math was not the issue with Tim at my side, but rather prep and application. To be continued. -

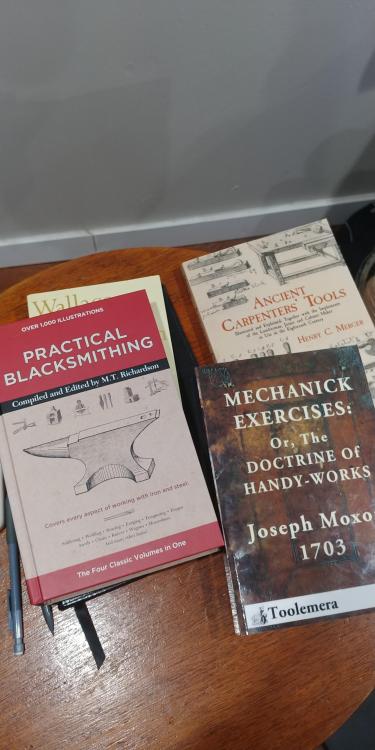

Nice! I'm in the market for some round frames too; I was recently gifted a pair of dark round lenses, I want to get some frames like yours to keep at the torch station. Also, mail call!

-

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

I grew up in the Dupage County, moved away for school and work to KY for about 7 years. Ever since I have been back up here, the idea of it being "home" is slowly losing its sentiment. Like you say, just a place where some family and friends stay. My wife has inherited a good acreage where she grew up in KY; been in her family for 100+ years and one day in the near future we will build on it. I hope to do the same one day! One thing I find common in IL is all the talk of wanting to get out; very little pride in residence and even less attachment. I can't help but hear and feel the opposite when in KY. I often share in Thoreau's thoughts after he first saw Walden Pond: "That woodland vision for a long time made the drapery of my dreams." -

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Kexel, I meant not to imply any ignorance. I merely saw that a generalizing conversation was being had about the state in which I live. Considering that we have several members here on IFI who reside in IL, I figured a summary of the laws would be helpful for all of us. -

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

You cannot bring it into IL public schools either if the blade is any longer than 3", according to the American Knife & Tool Institute. This is also true of any building or land supported at least in part by public funds. More specifically, you cannot even be on a "public way"(street, sidewalk or road) within 1000ft of the boundary. However, the state does have to prove that the violation occurred knowingly. Meaning, if you did not know that the property was partly supported by public funds, you must prove that. Knives that are legal to posses in IL: Balisong or butterfly knives; Disguised knives such as cane knives, belt knives and lipstick knives; Throwing knives; and Bowie knives and other large knives Legal in IL with a Firearms Owners Identification (FOID) card Switchblades; illegal without FOID card. Law gets confusing when considering automatic assist blades. Illegal Knives in IL: Ballistic knives All other knives are unrestricted absent unlawful intent. -

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, Thanks for that. Makes a lot of sense and saves me the labor of attaching the pivot rig. I thought about maybe spray painting it with some rust resistant stuff and then a finish with something slick. I like the paste wax idea too. And if I truly was mechanically savvy, I would attempt the blower idea for sure. Now to just get those chains! Nodebt, Ahh I see! Yes, that could be really helpful. Might just do that. Right now the bucket sometimes dips too far... and only once did it pull the lever from my hand. Otherwise, it only dips a few inches and is pulled up immediately. My current thought is that the springs, when tightened, will prevent that completely. Works for my neighbor's plow, anyway. -

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

M.J. Lampert, Thank you. I wish I had the mechanical foresight to rig a quick-connect, but this project is actually among my first mechanical ventures. It is detachable, just not easily haha. I based its design on the 4-wheeler plow I fixed up for a neighbor the day before, only because fixing it and subsequently helping him mount it, gave me good insights of its mechanics. His attaches not only at the very front of the vehicle frame, but near the belly of the frame as well. Mine attaches at the front and only slightly further back, near the front axle. I think you are right about a slight angle allowing for less resistance. What I might do is fabricate a two-piece triangular mounting bracket with a few pin holes in it which would allow for the angle. I'm having trouble describing what I mean: The bracket would grasp the square tubing on top and below; the pin holes would be in the center of the triangle, to the left and to the right. If I want a straight forward plow, I put the pin through the center hole, if I want it at either angle, I pivot the shovel and pin it at either the left or right hole. It's a maybe for now as the snow keeps coming! Woke up to about 4 inches and it's not stopping for another 5 hours, apparently. Nodebt, I am having trouble picturing an adjustable skid. But what I learned from my neighbor's plow is that speed and the strength of the springs allow for easier passing of cracks and bumps. The springs won't let it dip under the front tires, while also pulling it back up into position quickly when it does get pulled down by any impediment. -

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Due to the lift the springs provide, the handle and arm are used to push the shovel down; once it catches a scoop, it pretty much holds itself down. And yeah, when I come to a small curb or wide crack in the pavement, it allows me to lift over the curb in anticipation. I hope to be able to simply pass over a curb or crack after increasing the tension of the springs. A blade might help that a bit, but it's mostly to slow deterioration of the steel of the shovel I think and to provide some more rigidity. Yeah, I think I will do both sides because the snow sticks to the belly of the shovel pretty easily too. I think one side cut would be helpful if I fabricate a way for it to pivot at an angle. -

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

To add to the wildlife conversation: A couple weeks ago, I read an article in a local newspaper about a territorial Great Horned Owl that was swooping down at passersby from a tree in town about 15 minutes from ours. The week before that, my wife and I saw the silhouette of a large owl looming in one of the maples that surround our house... I like to think it was the same one! Lately, I've been trying to keep up with all the snow we have been collecting up here. We have a pretty large driveway and live on a corner; even with the frigid temps (-21f wind chill at one point!) and heaps of snow, people still like to take their daily walks, so I feel it's only right to clear both sections of sidewalk that border our property. Well, after a while, manual shoveling gets pretty tiring. I don't have the cash for a blower or truck and plow... sometimes a good neighbor will stop by with a plow and clear it off for me, but it's my responsibility dagnabbit! I had to find a better way lol. I earned some help and some cash the other day after I fixed (multiple welds & replaced the blade) a neighbor's 4-wheeler plow, but again, I can make my life easier myself... right? So, I built myself a plow attachment for my ride-on mower. Aside from a couple bolts, everything I used to build it was scrap. The shovel is one half of an old air compressor that had sat for years outside and had a couple holes to begin with. The springs are 3/8?" coil spring from a garage door that I cut and fit; the rest is scrap sheet, tubing and angle iron. The control bar is scrap conduit and yard-tool handle. It still needs some tweaking here and there, and the tires definitely need chains, but it works just fine up to about 5 inches of snow... any more and I can't do much without chains. I also think I will cut off the left and right walls of the shovel, tighten the springs and add a blade soon. Pay no attention to that mess of a garage lol. I wish I had taken a better picture. If anyone is curious, I can upload more pictures later when I am home. -

What is this axe????

Red Shed Forge replied to Matt Scanlan's topic in Axes, Hatchets, Hawks, Choppers, etc

No Worries, Matt. Thanks for sharing and searching! -

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Thomas, My wife the nurse would have been furious, especially with the dog. I'm sorry to hear you had such a rough day; I shudder at the scene in my mind! I nicked the tip of my thumb this evening on my table saw while processing some tinder for a charcoal burn. After a proper cleaning and bandaging, she might as well have cauterized me considering her scalding reprimand of my incompetence! Sidewalk Cold Work This afternoon as I was rounding the west side of my front yard with a bundle of willow in my arms to cut in the garage, I noticed a guy stop on the main road just before my driveway. He then put it in reverse and backed around the corner onto the intersecting road (I live on a corner), attempting to turn around on the main road. Unfortunately when he did so, he backed up over the snow bank and the curb and straight into the stop sign that stood on the corner, knocking it right over. He saw me see him do it. I smiled, waved, set down my bundle and headed his way. "Well, it's not the first time its happened!" I said. Truly, it happened last summer when I wasn't home. It was a bit worse that time and the Village took care of it, eventually. "I would fix it but I would have to go get my tools", he said. "No worries, I've got the tools." My garage just steps away, I went and grabbed a 1/2" socket wrench and pliers, cranked the bolt off and removed the remaining chunk of post from inside the female end of square tubing buried in the ground. We noticed that due to the way the post broke at the base, it was bent on one side of the square tubing and needed to be corrected to fit in the receiving end again. I went and grabbed a 2lb hammer in the garage. When I got back, he had the working end of the post resting atop a brake rotor --yes, an unrelated brake rotor was found mysteriously embedded in the snow bank-- which was placed on the sidewalk. He held the long post level with the face of the thin, momentary, urban anvil as I took to it with the hammer, making quick work of the shape we needed. With a light shimmy and little more force with the hammer, we sunk the post into place and bolted it back together. In no more than 10 minutes we, as strangers, shared in a little civic work. While attempting to part after exchanging niceties, a stutter-step and shoulder-lean occurred between us as we both resisted the inclination to shake hands. An unfortunate, unnatural, confused consideration of the moment. I walked back to my willow, to the garage and back to work toward pyrolysis. -

What is this axe????

Red Shed Forge replied to Matt Scanlan's topic in Axes, Hatchets, Hawks, Choppers, etc

Did anything ever come of this? I'd hate to keep the trenchant groove going here, but this is no mere quibble among such enthusiasts; the people need to know for certain! Did those who contacted outside sources ever hear back? Any chance we can still get that video? -

Visit to Historic Furnaces of LBL

Red Shed Forge replied to Red Shed Forge's topic in Everything Else

I would love to go fishing there one day. It's also a great place to go if you enjoy muddin'. Turkey Bay ATV area was my first experience in LBL. Should have kept to the lighter trails as I got stuck pretty quick in my old Cherokee lol. -

Visit to Historic Furnaces of LBL

Red Shed Forge replied to Red Shed Forge's topic in Everything Else

Happy to share it, Frosty! Here is the link: https://www.landbetweenthelakes.us/seendo/self-guided-activites/iron/

.thumb.jpg.393aa4af3d7a487945ec94f918847294.jpg)