-

Posts

226 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Red Shed Forge

-

Over this passed winter, the owner of the bell informed me that they do not plan to go back up to their WI lake house until this coming summer and not to rush on the hanger. Well, summer is right around the corner, so most of my time at the anvil lately has been forging a mockup hanger. The time and therefore anxiety relief the owner has given me has also allowed me to take a step back a decide the best way to tackle this (or so I hope!). I've decided that instead of 2 hangers mounted to a large connected back bracket, I am going to make one hanger that holds a larger yoke that holds the bell yoke at each end. I am struggling with my description here, but think of a bucket hanging by its handle on a hook. I think this will give the owner more options when deciding where to hang it; it seems they are having difficulty deciding whether to hang it on the side of the house, below a balcony at the aforementioned "T" section, or on a tree. The pictures below are of the mockup scrolls I forged this weekend and last night. On the finished piece, I plan to connect the scrolls to each other and to the mounting bracket (which will be the wrought iron piece) with collars. The stock size is 1 1/2" x 3/8" hot rolled; the collars will be 1" x 3/16". When forging the finished product, I want to focus on refining the fishtail ends of my scrolls. I also hope to refine the general fluidity of the scrolls with a scrolling fork. If anyone with a better eye for ornamental work has any suggestions, I would greatly appreciate it.

-

Pat, When I was working outside the Red Shed in my yard, I built a stand for a 35lb bench vise that I have. I dug a hole in the ground, buried 4 chunks of 4"x4" cut to the length of the depth of the hole and surrounded it with cement. I made sure not to completely cover the 4x4's with the cement as I would need to access the top of the wood after it dried. As it dried, I welded an 8"x6"(?) steel plate to the top of an old car axel, bracing the plate with supports that were also welded to the axel at an angle. The axel still had its wheel connection (sorry, don't know the proper name) attached to the other end. I then used the lug nut holes in the wheel connector to mark spots on the buried wood, drilled holes and attached the axel to the top of the buried wood with 6"x 3/4" lag bolts. It stood just a bit taller than my bellybutton and I was comfortable with that. The steel plate on top also had holes drilled in it which I used to secure the bench vise. It was nice and sturdy, but I took the advice given to me at the time and I did not beat on it whatsoever as it is still just a bench vise. Still handy for twists and general holds, though. I understand not everyone has a spare axel available, but maybe something else sturdy will work for you. I think you will have trouble with it tipping over if you mount it to an unsecured smaller stump or 6x6 you mention. Hope this helps.

-

Yes, very nice score! Good for you.

-

With regards to blacksmithing: When I first got myself an anvil, built myself a forge and found a hammer and some tongs, I immediately thought to myself, "awesome, I am now able to do all these cool things I see other smiths doing! I should start telling everyone about my newfound abilities!" And from there I took on some commissions; mostly small things, but one way outside my true novice abilities. I haven't given up on that one as it is still a WIP, but I certainly jumped the gun. I wish I had the wherewithal at the time, in the midst of my excitement, to distinguish between ability and capability. What I can do now vs. what I will eventually (with practice) be able to do with the tools I have acquired. With regards to life in general: After high school and 2 years of community college spent trying to "figure out what to major in", I wish I had someone in life influencing the pursuit of a trade. I got that influence a little later, after meeting my wonderful wife. Of course, change is among few constants in life. Here I am between the change I made and the choice I made in school, enjoying both worlds but favoring one.

-

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

We had some strong wind gusts last night that were beating up my fence again. While at the anvil practicing for a project, I looked up to see a middle section of the fence swaying waaay too much in and out of the yard. It had broken at the base, just like the last section I had to fix. I saved this one before it fell flat by quickly forging a support bracket for its base. I grabbed a 2 1/2' piece of scrap leaf spring, drifted a hole at each end and bent it at 90*; the long end ran up the broken post and was lagged in, the short end was staked into the ground. I used the double-stake base of a scrapped shepherd's hook, driven through the bottom hole of the spring to stake it down. It holds stronger than before, that's for sure, but a temporary fix no doubt. I will probably have to do the same to the other side as well... what a good way to introduce this hobby of mine to the new neighbors! The rest of the fence seems nice and sturdy, but it is probably time to replace that old thing . -

Really diggin' the porta-bandsaw action on here today. I got a Bauer from HF on Christmas and have enjoyed it very much since. I go through blades pretty quickly on it, though. Maybe it's the medium-to-high carbon I have mostly been cutting.

-

Good point. Seems more likely that a chunk broke off.

-

I would take the advice previously mentioned: ring and rebound test, etc. If it's not close to you, ask the seller to send better pictures and proof that it is a Trenton and has good rebound before driving out to see it. I am not in the market for an anvil right now as I have 2, along with other heavy steel objects that will help me move hot steel, but I do not see this listed within 100 miles of you and me on FB marketplace or craigslist (the extent of my search). There is however a 200# Hay Budden for sale in Skokie on CL, just outside the price range you mentioned earlier. Might be able to talk the seller down a bit. Basing my comparison on pictures alone, the HB already looks like a better choice. And at 200# it would be a bit easier to pick up and bring home. I know very little about anvils in general, but I am suspicious of the second step/chipping block/table too. Could be that a new plate was welded to the top; I would want to know how and WHY they did it. And of course, if it is truly a hard plate.

-

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Got my Oxy/Acy tanks swapped out this morning, man that stuff is expensive! I think the guy said prices jumped $4-6 between the two recently. I did some cosmetic work (rust removal, primed and painted and rewired for better lights) on a neighbor's trailer this weekend, so that paid for the tanks, but sheesh! -

Welcome aboard and I hope you stick around; speaking as a beginner myself, I can say this place has been a huge help in many ways. I'm out here in the 'burbs too, whereyat? I've been very fortunate to receive a lot of steel gifts from generous friends and family over the last couple years and am always happy to pay it forward; if you need some loaners, want to make a trade, or want to dig through the hoard for a few freebies, let me know! Send me a PM and I'm sure we can work something out. -Alex

-

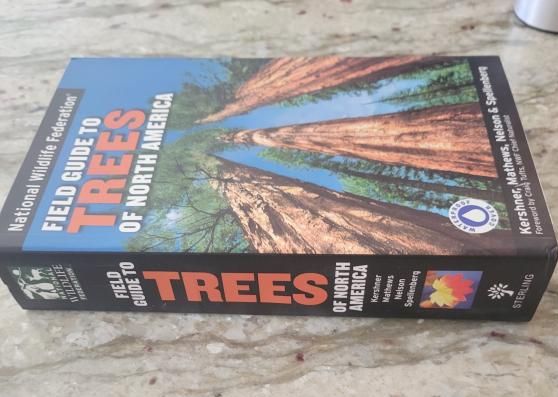

Hey, nice haul. Mail Call! The traveling Amazonians lost it for about a week, but the book finally made it to my front door. I made my wife send me a picture of it as I'm at the office lol. When I first started making charcoal, it was recommended that I start keeping a running catalog of the timber I char to make it easier to identify. It was counselor SLAG (thanks!) who made the suggestion, IIRC. The catalog has been a fun project so far and is certainly proving to be useful. I expect this book will be heavily cited throughout, though I am hunting for more! I think I will check out the Morton Arboretum's library next.

-

Cool, I'll look into it. I have 1 spike that I suspect is WI as well. It's about twice the length of a RR spike and maybe 3/4" to 1" square. I cant decide what to do with it but chunking and welding it together like you did certainly crossed my mind.

-

Nice man, keep on grindin'! Been a while since I've skated a bowl, for sure. I remember one day we just wandered around a few subdivisions looking for empty swimming pools like they did in the skate videos we would watch. Never found one lol.

-

Born in '89 actually haha class of '07! Although I took a couple woods classes in school, skating totally taught me the "if you want it, build it if you can" mentality. We called them boxes: 10'x8' rectangles of plywood and 2"x4"s with ramps in the middle. Angle iron the corners and start a game of S.K.A.T.E on the driveway. Frazer, nice find! Hope you can forge it into the hammer; that's on my list of "one-day"s too.

-

Haha yessir, '89. Oh yeah, cops would take it if they could keep up! lol. All the burbs tried to ban it everywhere you went and would say, "look, we built you this nice skate park with steel ramps and halfpipes for you to play on." Problem was, we learned how to skate jumping staircases and loading docks, grinding concrete ledges and handrails with our small groups. You want me to wait in line on a halfpipe only to drop in and smash into a little kid who cant move in his bodysuit of safety pads? Get real. Some would have a nice bowl to skate, but again, too many kiddies crying at the bottom because they collided with another one. Yeah, gimme them skate stoppers and take my wax.

-

"Skate stoppers," they're called around here. Started turning up after my generation learned how to shredd. They end up causing more damage to the city though; us delinquents would just bring a crowbar with us on each sesh. Couldn't 50/50 or 5-o grind after the concrete would come off with it, but nose and tail slides were still viable. Sk8 or die!

-

Great picture, thanks! Now I know what to look for when shopping around.

-

Gotcha, thanks!

-

Frosty, That is certainly positive. And that's a good way to put it, you wouldn't care if you didn't feel the need to say anything. Thanks. John, Yeah, I remembered that late on this post. Didn't keep it in mind, I should say. I guess that is what I was trying to apologize for when I mention "anyone who looks at my decision and acts similarly in the future." I appreciate you guys trying to help. And just for the record, I'm not ignoring Glenn's comment. I thought what he wrote was a good concise summation of all this and we spoke briefly via PM.

-

Thanks for that, Scott. Alex

-

John, I think I was looking at those exact glasses the other day on Etsy. Almost bought them myself but I wasn't sure if I would be able to replace the lenses with the dark lenses that I have. Just by looking at the picture, I can't figure out how or if the frames allow for replacement lenses. Do they?

-

Alright everyone, I've learned my lesson: The risks of repairing the bottom rung of a ladder far outweigh the reward of helping your neighbor when he is in need of a quick repair. My apologies first and foremost to member No Debt for snapping back. This is not said facetiously. My apologies also to anyone who looks at my decision and acts similarly in the future; please consider the potential for expanding risk. Another personal lesson learned: Some things are best kept to yourself. Though it is likely already transparent to some based on my initial post, it feels good to be someone's first thought when they're in need of a repair. And 'ya know, I almost feel silly admitting this, but it feels good to have a place like IFI to share such projects/jobs to a group of people who will understand the sense of accomplishment one feels at completing a unique task like this. I've got many great friends and family in my life who support my iron and steel endeavors, but very few who really understand the endogenous drive that develops. But alas, the purpose here is more about education and practice than it is individual gratification and encouragement. Thank you for viewing and reading my post and thank you to those who complimented my work.

-

Thanks for the compliment. That's very interesting, I never would have thought to check into ladder laws. I figured it was up to the owner of the ladder to choose what to do with his ladder, especially since he didn't plan on reselling it. I will look into the discretions we have with our own ladders for possible future ladder repairs.

-

I wondered how that might have been done as a hot punch. Would you use the drift as a bolster in that case? If drilling: do you mean you would put a chamfer on the inside of the hole of the outer bosses?

-

I'll shake on that. To each his own reality!