-

Posts

226 -

Joined

-

Last visited

About Red Shed Forge

Profile Information

-

Gender

Male

-

Location

Benton, Ky

-

Interests

Swinging large hammers, building useful things from scrap and working on a sustainable lifestyle.

Recent Profile Visitors

1,160 profile views

-

JHCC, Cool, thanks for that tidbit. It would be pretty neat if they were made at the same time! I'll have to check that out one day, I'm always looking for some smithing tools too. Thanks for your thoughts, everyone. I can't wait to work with her.

-

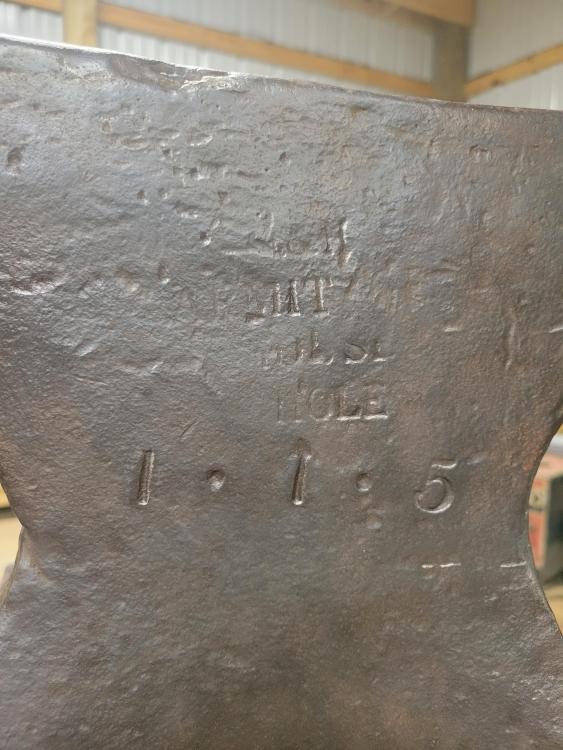

Hey folks, Been a while! Almost a year, sheesh. I just had to jump on here to brag about my recent acquisition An M&H Armitage Mouse Hole 1.1.5 (145lbs) If what I'm reading is correct from the folks with AIA, that puts it around 1820-1835 production..? I bought it for $500 US from Joe, a friend of my wife's late grandfather Cotton. He's posted up on KY 68, 2 minutes west of me, for the annual 400 Mile Yard Sale going on this week. He got it at an Amish auction; I forgot to ask which county. Maybe a little high on his asking price, but he wouldn't budge and I had to have it. I know nothing about the 2 stamps at its front base, but if anyone has a guess I would be happy to hear it. It rings nicely and a ball peen hammer rebounds well, though I do not have a ball bearing at the moment. I did not do any doctoring in excess of a wire wheel brushing and some oil, although Joe admitted to me that the tip of the horn was in poor shape when he bought it and so, to my dismay, he took a grinder wheel to it and rounded it off a bit. All in all I am very happy with it and as soon as I get the forge back up and running, it shall be fed some hot steel. Thanks for checking it out.

-

Thomas, there is no telling how often my wife would ring a bell strung up like that just to scare the heck out of me in the shop haha

-

Thanks, Das. It would be cool to see what you can come up with for the school bell hanger if you end up making one.

-

For real! I was getting worried. And it truly was a scheduling issue that was preventing them from picking up. Lots of travel for work I guess. They did say it was going to be a surprise for him, yes. Just makes it that much better.. cant wait to see it hung up!

-

Yesterday the customer was finally able to come pick up the fixed bell and forged hanger. They love it! It will eventually be hung at the family farm in northern Wisconsin and will be given to the family patriarch as a Father's Day gift. Again, I am truly honored to be part of the bell's history; I hope it endures for another century and beyond.

-

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Really cool gator Das, I'm sure it will look great in FL! -

Yup! It will be a 30'x30' pole barn with a "barn style" roof. Already made the down payment! The plan is to make the top portion into a loft apartment which we will live in while we save for the house build. A year without $6k in real estate tax payments and no mortgage will be helpful, that's for sure. Most of what we own now will be in storage below us and some in my FIL's 40'x40' if necessary. This will require a separate area for smithing... and I'm eyeing the 80+ year-old wooden barn just a stone's throw away on the other side of the highway!

-

Gotcha, Glenn. Thanks. Thanks, Frosty. George, thanks for relaying that. If it starts getting close, I will check with each state. And I'll take the congrats! haha. My wife inherited 10 acres of her family's land, and with the way houses are selling right now, we figured this is the best time to make the move. Even with the egregious prices for lumber and metal right now, we might still come out on top after we build. I look forward to eventually having a bigger shop/smithy, having more than a .25 acre of space available to us and not having to worry about annoying neighbors with the sound of my hammer blows. Not to mention all the oak, hickory, maple, pine and elm I could ever need for charcoal. I plan to do a post about leaving Red Shed Forge behind, where I will be setting up my temporary smithy after the move, and plans for a new permanent smithy. I'll also take this opportunity to thank everyone who participated in this post. Whether you gave advice, encouragement, a word of caution or a verbal pat on the back, I appreciate you. I'll always be grateful for this virtual community and I am excited to see what more I have to learn from it. -Alex

-

I will set a deadline in writing for sure, but to the curb? I thought about just saying if they don't pick up, it's coming with me to KY and they will have to get it if they're ever in the area. It would look nice on the new shop haha.

-

Thanks, Frosty. I have not told them we are moving yet; as of yesterday the big pieces of the move (job acquisition & land being cleared for a build) have finally come into place. But yeah, I'm sure the news of us leaving will get them to act so I will be informing them next week when our house is listed if I don't hear from them beforehand. The bell is not mine, they hired me to also fix its cast iron yoke that broke when they were removing it from its original mount.

-

I've been waiting for the customer to pick up before posting a picture of it completed, with the hopes that the customer will send me a picture of it mounted at the WI farm, but after more than a month of waiting for them to show up, I think it will also be a while before they even get it mounted. We have agreed several times on a pick-up day, but they either have something come up last minute, or they simply do not show and do not give a reason. Not a complaint, as they insisted on paying me without even seeing it, I am just eager to see how they like it. My wife and I, however, will be moving back to KY in the coming months, so I might have to offer a delivery soon. Anyway, I snapped a picture of it mounted to the Red Shed a few weeks ago for my own sake. As you can see, I had yet to paint the bolts and fasten them properly where the yoke meets the hanger, but they are painted now and I touched up where my wrenching removed some paint. I decided to go with the Rustoleum hammered black paint, as recommended.

-

What did you do in the shop today?

Red Shed Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexandr The Great Smith. Beautiful railings. Always stunned with our work, thanks for sharing. -

Cool, thanks I'll look into getting that one for sure.

-

George, If that ain't the truth. Well said. I've tried to keep in mind my personal and familial posterity on this project; the bell itself begets the thought of time passed and generations of users and viewers. It's been a daunting but proud moment in my smithing experience so far. Daswulf, Thanks! I've never used Duplicolor, I'll check it out. Truth is I can't decide if I would go with matte or gloss! Sounds like more tests to run... Goods, I considered round coil spring too. I've got a bunch of it laying around. I thought about wrapping it like you said but with leaves on end. I will be finishing up a project for my wife here soon, so I think I'll attempt it there.