-

Posts

152 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Chicagoland, IL

-

Interests

Green-as-grass hobbyist just starting out.

Recent Profile Visitors

877 profile views

-

What did you do in the shop today?

MaxwellB replied to Mark Ling's topic in Blacksmithing, General Discussion

Mac, took me a minute to see the poker. I was focused on that wonderfully full glass and wondering what sort of damage I could do it. I have to settle for some McMasters Canadian, with some Jim Beam orange. What can I say, I'm a cheap date. -

What did you do in the shop today?

MaxwellB replied to Mark Ling's topic in Blacksmithing, General Discussion

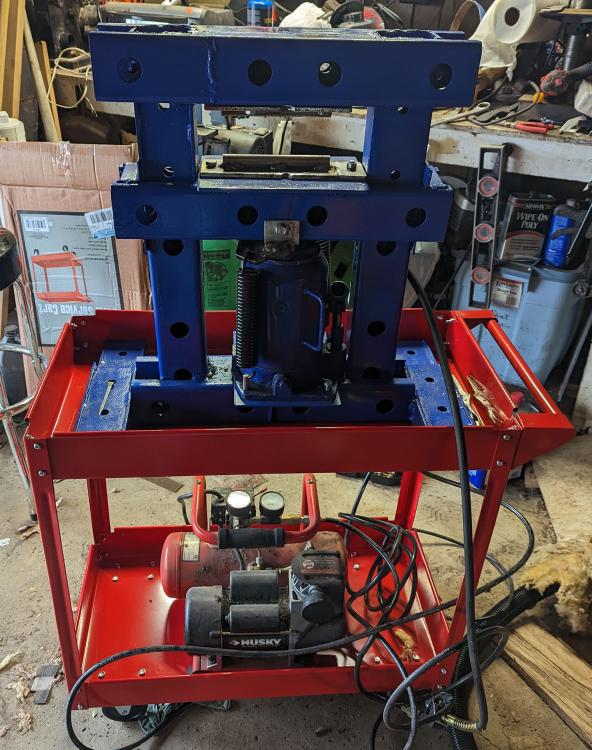

Picked up a cheap-o cart from Harbor today to put the press on. Press is a 32 ton air jack I got for around $140, and the frame was built for free by a friend using scrap steel he had. Now all I have to do is get a compressor that's not a steaming pile. -

What did you do in the shop today?

MaxwellB replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Taxes. It always comes down to taxes.

-

Thanks! And yes, there is a decline in the letter opener business. This was for an older (than me) guy, who still does a lot of things old school. Still writes checks, still buys stamps, that sort of thing. Although I will say that I still get some things by mail that I give a toot about. So I use mine maybe 2x a week? And if I don't have it handy, or can't find it, or just can't be buggered, I just tear the side of the envelope off like a heathen.

-

I would definitely take it into the house and do all the work with it... However I don't have a whole lot of room with the other collections of miscellaneous garbage taking up space. I take care of an elderly parent who is a hoarder. So there's a constant struggle with clearing space off just to have it re-clustered shortly after I turn my back. I have other projects to keep me occupied until warmer weather, so while the box in the garage is taunting me, it's not beyond ignoring. Gives me something to look forward to, getting back into the garage shop and cleaning it out, re-setting up my workspace, and trying to maintain it all over again. Until, of course, I win the lottery and can have my own dedicated shop. Ahh, to dream.

-

Thanks! He was gushing about it. It's not hardened or tempered, because it's just for paper. Hopefully it serves him well.

-

I'm a little late in posting this, but over the holiday break I managed to finish up another letter opener, which was given to a friend who gifted me a butcher block cutting board. Recycled coil spring blade, Zebrawood & resin handle.

-

I just got my Mr. Volcano, and I'm dying to set it up, but I'm worried that the curing/setting/hardening etc. of the rigidizer and the satanite will be hindered by the cold. Not to mention I fear the cold would be detrimental to the setup, as liquid in the mixes might freeze before things are set, and when firing up the burner to cure it'll create issues. So it's sitting in it's box, waiting for warmer weather. I've also got some plistix I'm planning on topping the satanite with. My devils forge is still a great forge, but with it being a 2 burner I'm just wasting fuel as I'm not making that big of items right now. Patience has never been one of my virtues, and the wait for March when I can count on the weather turning and staying that way is killing me slowly.

-

MaxwellB started following Does this count?

-

I made this over Memorial Day weekend, realized I hadn't posted it here yet. My first forged item that I'm proud to show others, something that I learned a fair amount during the making of. I've had plenty of compliments on it, and interest from some of the people I've shown it to for one of their own. Blade is from coil spring, handle is epoxy resin and mica powder. There are some pretty obvious flaws to it, but as a first I don't think it's horrible. I'd love feedback too so the ones I make for others will be closer to perfect.

-

People do make "scrapmascus" out of bandsaw blades and higher carbon steel. I'm not sure how well the finished product will be for your use since you're going to have mixed hardnesses in the blade and varying edge retention. Now, what you could do is get your billet prepped and then forge weld on an extra piece of spring steel to make your cutting edge so you have all the prettiness of the damascus pattern that you make and then the cutting edge is a solid, known steel that better takes to heat treat, sharpening evenly, and edge retention.

-

Flexible Graphite sheeting in forge build.

MaxwellB replied to J Hiser's topic in Insulation and Refractories

I read the data sheets as 5000C in a vacuum, which definitely isn't achievable in your average forge. I'm assuming you're still lining everything with ceramic blanket, and this is the inner-most layer? -

A few questions before I start building my propane tank forge

MaxwellB replied to Fallon's topic in Gas Forges

1 & 2 - You don't need to rigidize the first layer if you're doubling up. Only the fire-facing side needs to be ridigized, and since you're looking to put a refractory on top, you don't absolutely have to rigidize at all. It will make the refractory process easier, but for sake of uniformity with other advice, no... Just rigidize the top most layer. 3 - Yes. Your refractory should be completely cured before you apply the IR. You will want to repair any cracks that form during the cure and make sure your refractory is 100% ready to go before applying IR. 4 - KOL doesn't dry. It cures. It acts like cement, where the water creates a chemical reaction within the refractory and triggers the curing process. If you're thinking of mixing up 20lbs of KOL and trying to save the rest, you'll end up with a bucketful of solid stuff. Any excess you have after you coat the walls you could use to build sacrificial plates to put on the floor of the forge, as that will take the most abuse from stock poking and flux and other nasties. -

First thing I would try would be removing the flare and the pipe after the flare, and just trying the burner with the 8" nipple going into the forge. Read what Frosty said yesterday a few times if needed, especially concerning mixing tubes and bell reducers. The guy really knows what he's talking about. I'm building a few of his burner designs myself, and am waiting for one more shipment of (much cheaper online) parts before it's completed. Your forge does look pretty nice though. I especially like the expanded steel stock rest/brick holder.

-

Mikey's got the right idea, probably the quickest and easiest. Another thing you could do is get a 90 degree elbow and put that on the end of the line so your propane hose is coming in at 3 o'clock instead of 12. Add the post and hook, and you're golden.