-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by killbox21

-

1862 civil war barn and anvil 1/20 scale replica

killbox21 replied to Welding Rod's topic in Member Projects

Very nice -

What did you do in the shop today?

killbox21 replied to Mark Ling's topic in Blacksmithing, General Discussion

First skinning knife on the new pheer grinder, and the first time using a small wheel attachment. The finger grooves really make a good feeling knife. Now for a sheath. -

I used Corruseal rust converter on mine with good results. Great looking vise

-

Wow, I like it. Unique.

-

What did you do in the shop today?

killbox21 replied to Mark Ling's topic in Blacksmithing, General Discussion

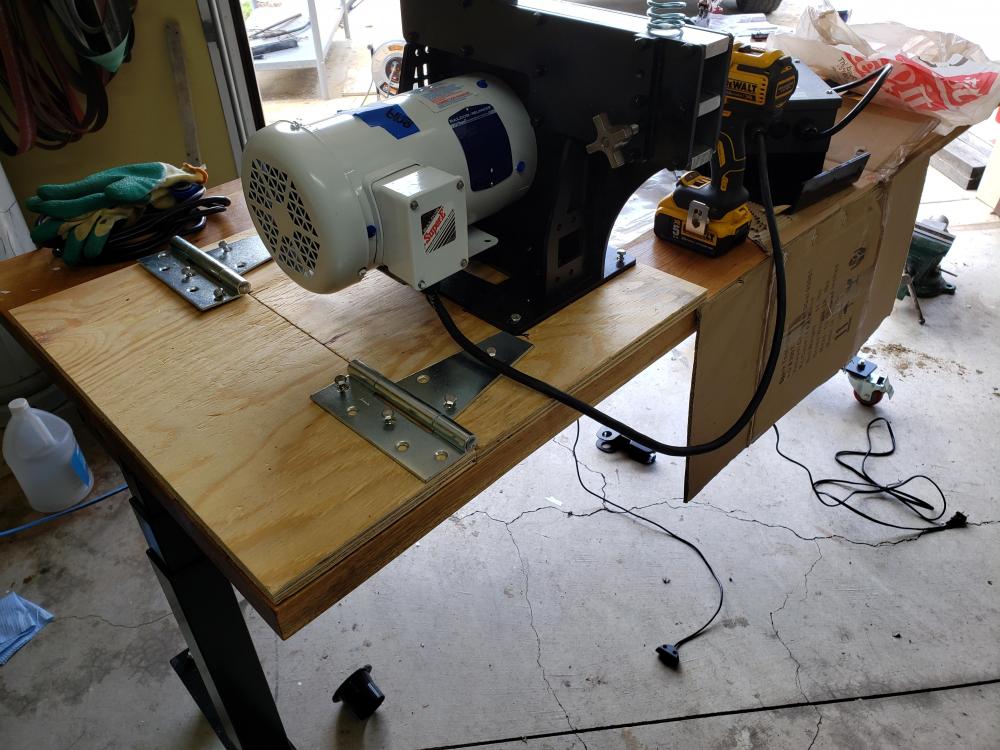

Almost got my horizontal bench mod done. I plan on drilling more holes so I can mount it with the bench dog holes, that way it's fully removable. -

It probably didn't even need it since I had to lube it up to slide it into the rubber sleeve, but 5" muffler clamps were a perfect fit and will not interfere with the 2.5 vacuum connection.

-

What did you do in the shop today?

killbox21 replied to Mark Ling's topic in Blacksmithing, General Discussion

While I wait on my drive wheel to arrive, I made a tree for the grinder attachments. Welds aren't pretty but they'll hold. Now for some paint. -

I have the 6" version and use it almost daily. Great vise.

-

What did you do in the shop today?

killbox21 replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Thanks guys, I will have a better idea once I get the grinder going. I was looking at a dust deputy type apparatus.

-

I have a pheer grinder coming next week, and in preparation for it I have been working on this shavings catcher. I need a small piece of pipe to attach a blast gate for the vaccuum when working with wood. I will cut the 4 inch pipe to size once the grinder shows up. Going to run it all the way through the sleeve and have it a few inches above the water. Any other recommendations for this setup? I am really sick of the dust.

-

What did you do in the shop today?

killbox21 replied to Mark Ling's topic in Blacksmithing, General Discussion

After getting burned when my vise moved on me the other day, I decided it was time for a more permanent solution. Used some steel my buddy gave me off some gas wells and put concrete anchors through it. Only one in each corner for now, but I have 2 more holes if need be. You can see my old railroad tie vise post in the background. -

Since no place around here had a 9/16 fitting for the needle valve, I had the auto parts guy make me up a hydraulic line and got it going. No leaks, let it run about 15 minutes wide open. Any downside to this? He said the hose was rated for 5100 psi. So I don't see that being an issue.

-

Show me your Bottle Openers!

killbox21 replied to Arbalist's topic in Blacksmithing, General Discussion

Here are a few that I have made over the last little bit. The dice one I used a drill press to make the dots. -

-

Good idea on the hose rerouting. Thanks. I may replace all these hoses,it all looks old.

-

Thanks everyone. I also found a valley brand forge that looks similar, except that it has a door on the back. I did find another leak right where it goes into the tank, so I won't be able to see what it's really got until I replace that.

-

I cleaned it up a little. I don't see any markings anywhere. It has been well used from the looks of it.

-

I just traded an Alaskan ulu I made for this old 2 burner forge. She said her husband was a farrier before he died if that helps. I fixed some leaks and a stuck valve. It fired right up.

-

Show me your blacksmith pets

killbox21 replied to Glenn's topic in Blacksmithing, General Discussion

-

Thanks for the replies. I wasn't really going for anything other than practice. I bought some cheap rebar so I wouldn't be wasting time on expensive materials. As far as the shape, I was just messing with bends on the horn vs the side of the anvil and then bending them back. I am working with a bench grinder and angle grinder with sanding disk for now, but have started looking for a belt grinder/sander. I have been watching videos and reading this forum none stop. I plan on attempting some different tongs with the rebar this weekend. Thanks again.

-

Been playing around with rebar making knives. Had to work on a boat all weekend so I didn't get back into it until Monday. While they aren't the prettiest things, I do feel like I'm getting better with the hammer. I started messing with paracord for the handles. What do you think?

-

Can you please suggest or link some good all round tongs? I am completely new to this. Thanks in advance

-

I don't even know what 1045 is. Lol. I bought 3 pieces of 10 ft rebar to play with until I get my hammering technique down. I saw a leaf on another post I am going to attempt, but I really need to try to make some tongs or buy some. I can't believe how fun it was making that.

-

Wow, looks awesome, I am going to attempt a leaf.