-

Posts

166 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Awrksmokey

-

both fascinating ideas actually! I have a bit of a long name haha but it might work, I'll see when I make another of these knives.

-

bought an anvil. identification?

Awrksmokey replied to Awrksmokey's topic in Anvils, Swage Blocks, and Mandrels

ohh sorry! I thought I had already sent that in! here it is- It's slightly concave but pretty worn so I can't see very defined shapes. -

bought an anvil. identification?

Awrksmokey replied to Awrksmokey's topic in Anvils, Swage Blocks, and Mandrels

-

I bought this anvil a week or two ago but haven’t gotten the chance to take it out yet. at first glance i thought it was a peter wright, but the feet don’t look quite right. it’s stamped 1-1-17 which i understand to be 157 lbs by the hundredweight system. i was thinking it could be a mouse hole but some people disagreed. Do you guys have any ideas? it’s not marked at all other then the inspectors mark, which is an O, and the weight. thanks!

-

I vaguely remember reading somewhere on this forum that an anvil itself is used as a percussion instrument sometimes. There was a link to a piece of music that the anvil was used in, but my memory is a bit foggy and I can't remember if it was actually a smithing anvil used or a different instrument with the same name. It was pretty interesting though!

-

I was thinking about that actually... maybe I'll find a pin layout that I like the aesthetics of enough that has more than one pin in it. It's definitely a better idea than what i made, thanks!!

-

Thanks! I'm giving this knife away, so I won't be able to use it, but I do hope the person who gets it enjoys it.

-

I went to a different shop, and they had some nicer tools then i was used to in my home setup, but it was a pretty sizeable chunk of material!

-

I am definitely not a much of a bladesmith, but recently I forged out this small kitchen knife for my 500 follower giveaway on instagram. It is coilspring steel and a desert ironwood handle. I hollow ground it on a 4 inch wheel. At the thickest point, it's 1/8th inch thick. I think I should've forged it down a bit thinner. Anyway. I'm pretty pleased with how it turned out! Do you guys have critique or something you think i could've done better? Here are the in progress and finished pictures:

-

Amazing. I really like the middle fuller on the sheath as well!

-

Justin’s Smithing progression. [PIC heavy]

Awrksmokey replied to Justin Topp's topic in Member Projects

You could also make a striking anvil out of the forklift tine for your hammer making... i also do really like the sideways texture on the flower petals, even though they might have been folded wrong. -

What did you do in the shop today?

Awrksmokey replied to Mark Ling's topic in Blacksmithing, General Discussion

Yeah, the guy was nice enough to give me a spruce stump for it too. He was a woodworker, and apparently it was from the site of a church he built! DSW, that is a cool funky hammer! Is there a certain reason why it's shaped like that? -

Yup, I guess perfect can't really exist. But i can try to get real close!

-

What did you do in the shop today?

Awrksmokey replied to Mark Ling's topic in Blacksmithing, General Discussion

I bought an anvil!!! It's in good condition other then the chip in the foot. It's 157 lbs and looks like a peter wright to me but it doesn't have a makers stamp. I might make an identification post if I still cant figure it out after some more research. -

I did some forged the leaf in one of the pics with it, and I also did some forge welding and made a ball on the end of a rod. I also tried scarf welding, and that didn't work so well haha. More practicing to do i guess! I'd say it worked pretty well! I really like that sort of rectangular handle shape. The rounding part took some getting used to but I can really see why people like it now,

-

I'd also tried cooling the cheek that bulged out disproportionately and drifting it with one side hot, that didn't work too well either. When I make my next one, hopefully I'll just do it right the first time but the learning experience of learning to move the metal would be welcome too. We'll see. Thank you!

-

Thanks. I want to make another hammer now lol.

-

Hopefully I'll improve enough to be able to see that change. Only one way to do that i guess!

-

Thanks guys! I agree, it is much more fun using a hammer I've made instead of a hammer I bought.

-

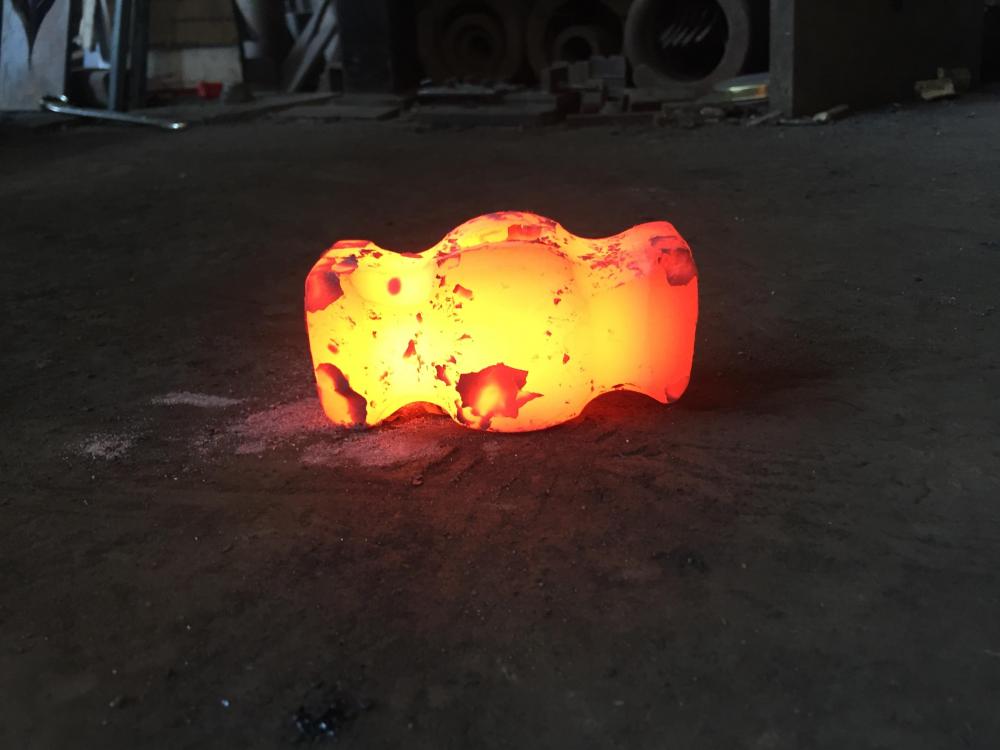

I'm forging my first hammer! It's been a ton of fun so far. I started with 3 inch 4140 round, cut a disc off and shaped the billet first. I punched the hole accurately (or so i thought!) and once i drifted it, I saw it wiggled a bit off center. I got some help trying to correct it by drifting to round then oval again, but it didn't really work sadly. I forged in the fullers and then forged the faces, round side into octagon and the flat side I hit the corners to octagon on the rounding side, but on the flat side i just smashed the corners in a bit. i've rough ground it and heat treated it, and this is what it looked like. The next day i heat treated it and finished grinding the faces. I made an 11 inch ash handle, charred the end a bit (for aesthetics mostly, lol) and put a walnut wedge followed by a steel wedge in. The hammer ended up around 2 pounds. I wasn't sure if this was going to turn out well at all, and even though there are a ton of annoying flaws I'll try to correct on the next one, I like it. I forged the leaf with the hammer too.

-

Well i sort of finished it. I ended up tapping it a bit more until it fit like Frosty suggested but I would like to try forge brazing at some point. Anyway, this is what it ended up looking like. I do think the first style i tried could be very interesting, so I'm planning on giving that some more tries until I can get it perfect.

-

Yes, i understand. I might try forge brazing (it seems like a lot of fun), but I haven't been able to get more fuel, so i may need to do the other option with my small propane torch. Hopefully I'll be able to get some more fuel soon. thanks for the input!

-

List of makers currently producing anvils

Awrksmokey replied to Jonnytait's topic in Anvils, Swage Blocks, and Mandrels

I'm not sure if this is the right place to say (maybe there's a 2020 thread?), but Alec Steele just announced that he's going to start making anvils. [Mod comment: the thread has been renamed to remove the year.] -

Why is it rubbish? It looks really good and functional to me.

-

It looks great to me! Functional too!