Mellin

Members-

Posts

115 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Mellin

-

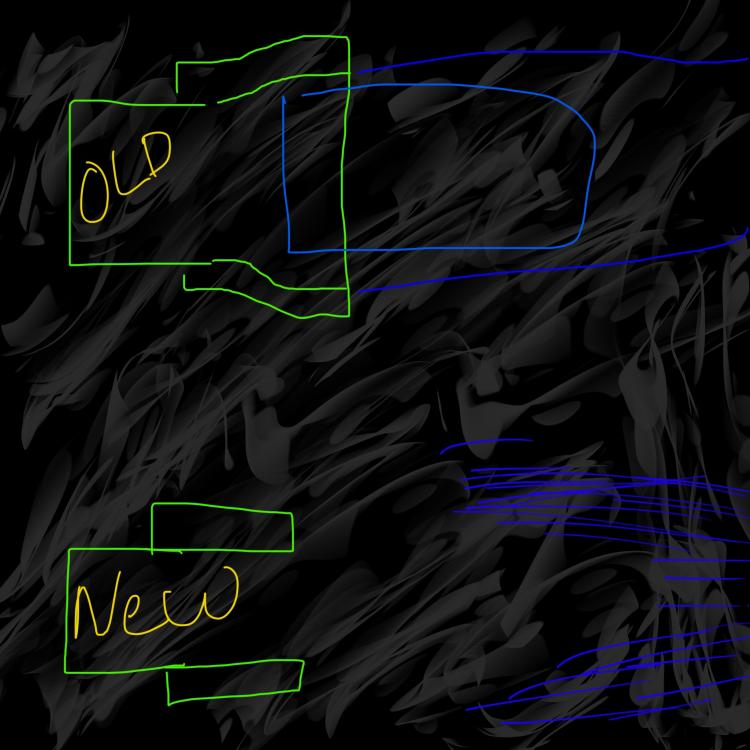

I am going to take a spare mig tip and shorten it down more as the flame has done something a wee bit funny to me. I took the time to draw this masterpiece and I am assuming that the mix is still too rich at the mouth of the burner to support combustion so it moves away from the burner? The figure labeled old (reference pics from March 29) is where the flame sat before, definitely within the flare. The new coupler pushed the flame way off I can only assume that is bad? Inefficient? My logic is The volume of air intake doesn’t change in my 2 situations so if a change in flare causes the flame to walk away from the burner it is rich so shortening the mig tip will induce more air therefore bringing the mixture closer to neutral?

-

I’m assuming what I referred to as a bench vise is what should be called a machinists vise. So a post vise can be mounted to a work bench without putting holes in the floor? I apologize for putting this in the wrong thread my misguided youthful intentions were telling me that these post vises are more rare than they actually are and that blacksmiths in the Midwest could make a jaunt on over to the scrapyard because we don’t have many scrap yards around here and the ones we do have aren’t selling to the public. I’m not a scrapper or scrap yard I’m not looking to get money or be anyone’s agent I thought I was doing a courtesy and after reading Glenn’s post Again I apologize to the curmudgeons and admins who had to take the time to move it.

-

Do the post vises mount to a bench? I have 3 bench vises currently.

-

Tp, Das thank you. I will post pictures and I would be more than happy to go back and ask if he would make a deal on all of them. He had a lot of stuff including a roll of barbed wire he said is extremely rare. I’m sure that is common to all junk yards. I don’t have any friends out here that need them, heck I don’t think I even have a local abana chapter.

-

I found about 5 post vises sitting in a bucket at a scrapped I journeyed to the other day I asked about them and the guy said he wanted 125+ per which sounded crazy. I will get pictures I don’t have them on this device. I know one did not work others did. Some were shorter maybe broken with threaded rod to mount it to something. They were painted bluish and had very machined looking parts.

-

Makes sense

-

-

Haha I happened to run into a family member in the plumbing business and he said that if I need more he has hundreds.

-

Thank you Wayne!

-

I did not adjust the mig tip but changing to the new "flare" made it so the torch could not support flame outside the forge. Inside the forge the flame seemed to move away from the flare but the flames coming out of my forge are shorter it feels like.

-

Is the one on the left the thread protector you speak of? I found a real plumbing supply and they gave me these.

-

When looking through the bin at the steel place I only grabbed the ones in the picture but they had a 275 gallon bin full of them. I originally only planned on using them for grinder stands but all your great ideas have me planning on going back. I have plenty of room for more. Charles you were right I took a look at them again and only the beveled face had the paint worn off. The backs are still painted and it doesn't like to come off. I didn't want to turn on the air compressor today so I didn't get after it with the air grinder and I'm sure that'll do the job. Thomas I preheated and postheated with a mappro torch. The puddle this stuff made when I welded it was very nice.

-

Correction : That should be harrow not narrow.

-

-

Power take off (pto) shafts are on a lot of things but an everyday example is a large truck with a transfer case that instead of going to another set of wheels goes to a device like an auger or sometimes tractors have them and can become lawnmowers. They could be drive axle material maybe 4140 I’m no expert.

-

I can tell you without question I wouldn’t want microtears all through my nasal cavities from when all of the non wear surfaces suddenly have stuff being drug across and up in. Meningitis sure can live peacefully in a persons nose till there’s an open door to your brain next to it. These kids are disgusting I don’t associate with either one of the last 2 generations. hammers propane metal fire Creedence Clearwater revival ok I said my safe words, millennials and fidget spinners begone.

-

If they were trying to get high that would be too easy. These kids are literally just sniffing condoms up their nose to make a video and post it online. I say garage but is not an attached building on the acreage I’m generally the only one in the building not that I can be free to be an idiot. Since this will be hardly structural I might just preheat weld and hit it with a torch for a while after I’m done. I’m welding a 1 inch square tube to the disc on one end then to a 3/8 plate on the other. My grandpa was a simple man and for as longer than I’ve been alive grandpa always had a bench grinder with one of these as a stand just making one like his and maybe one for a vise.

-

I can’t even begin to believe the stuff people are doing now a days such stupidity, that’s a complaint I’m sure every generation says about the next but this last 17 years has been a downward spiral of stupid I looked up a coulter wheel and one of the results was almost exact except mine are all shiny maybe even polished. What type of steel generally are they made of.

-

I just want it on hand I have certain chemistry texts and mechanical engineering books for various reasons. As to the concerns about K wool, I agree that it poses hazards that I would not expose others to however when I worked with it previously I used a 3m p100 respirator, nitrile gloves and a full face shield. I understand the risks but I also know precautions need to be taken into consideration. I would like a better option for sure but I don’t have the ability to use charcoal briquettes. I will look into heat treating processes.

-

That settles it, ill preheat with a torch and set on the wool stuff. It should stay hot long enough.

-

I don’t think it’s too bad in a normal situation to weld inside but I guess a couple charcoal briquettes shouldn’t be too terrible how long am I looking to slow the haz cool down to, I guess I don’t know the alloy because that may be a relevant question. side note if anyone knows the name of the set of books about metal alloys and their properties I want to buy them

-

Its a better idea and I could even use that as an excuse to build a frame for my big one into a fire bowl but I can’t do it outdoors and I think indoors might be obnoxious.

-

I am assuming a hand torch for the preheat, for the slow cool should I try to wrap it in that cloth stuff for insulating forges (that I cannot for the life of me remember the name of) and maybe stuff it under the cupped portion too or just hit with the torch for a while after welding.

-

I also got some blades that are flat with a single bevel sharp edge put on it they are considerably smaller. I can get pictures. I figure it’s the same kind of tool something that rolls and cuts stuff.