-

Posts

143 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Bristol, England

-

Interests

Electronics, Mechanics, Robotics, KnifeForging, reverse-engineering.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

The silica particles in the rigidizer will have clumped together at the points where the ceramic blanket fibres touch, as the water in the rigidizer evaporates. When the fibres are heated to orangey/red with a burner, the silica particles melt and flow between the fibres at the points when they touch. When the Ceramic blanket then cools, the melted silica hardens and locks all the fibres together, "Rigidizing" the blanket, so it can then be coated with Kastolite or some other flame-facing coating. The rigidizer won't work correctly unless it is heated to the melting point of the silica particles. Hope this helps. Tink!

-

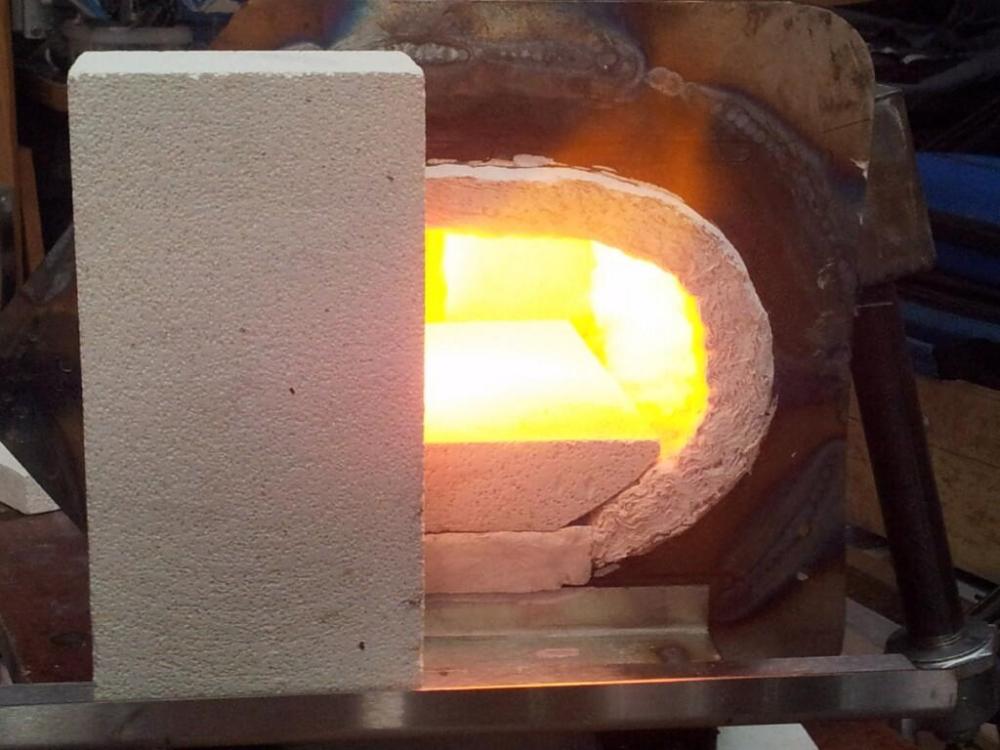

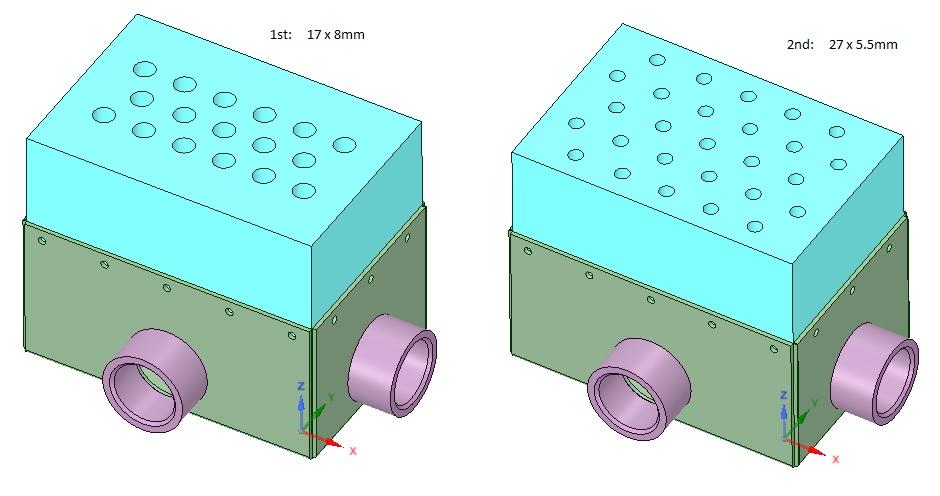

This is how I got my IFB NARB tuned.

-

Hi Duncan, The pipe length is a ratio related to the internal diameter of the pipe. I believe this ratio is to do with having enough length to give complete mixing of the gas and air before it reaches the flame at the end. It makes quite a difference with single-jet burners, but no difference if you are feeding into the plenum chamber of a multi-jet burner (NARB). It is something like 12:1. Here's a link to some values from a previous chat. As far as the size of the burner and diameter of the pipe, there is a rule-of-thumb that suggests a good 3/4" burner will bring a good 350cubic inch forge up to forge-welding temperature. This is what I based my choice on. I have used my AMAL 3/4" burner with ~8" pipe for single-jet use and multi-jet (NARB) use very successfully. The turn-down range on my AMAL is pretty good, so I'm glad I went for a single 3/4" rather than 2 x 1/2" burners. On the AMALCARB website, they sell propane injectors with a short-choke or long-venturi. The short-choke is really intended to feed a multi-jet burner and so doesn't really need to worry about mixing the gas and air so much. If you are going to use a single-jet burner, then chose the long-venturi version, as it has a correct-ratio expanding cone on it, that fits inside your length of malleable steel pipe nipple. As the long-venturi version will wok with single-jet and multi-jet, I went with that option. I also followed TimGunn's advice and got 2 sizes of jet for my 3/4" AMAL injector when ordering. From memory it was a 90 and a 110 sized jet, but it is cheaper to order an extra jet when you order your burner. I have played around with both jets, and one worked better in a single-jet and the other size was better with my multi-jet setup. You really need to work through the Burners-101 and Forges-101 threads to glean this info. It will take a while, but you will learn a lot from it. Hope this helps. Tink!

-

If you're based in the UK, then the AMAL burners are a no-brainer! Super adjustable and really hot.

-

tinkertim started following 1/4" micro burner "pocket rocket"

-

Hi Aquamo, Welcome to I Forge Iron (IFI). You might want to put your location and Country in your Profile info, as you might find members close to you, and many answers to questions are often Country-specific. I think you're assuming that all countries have the same types of bottle, which might not be the case. In the UK there are small bottles intended for Patio use that have flow-limited valves, but there are many other sizes that have no flow-limiting. They seem to have different fittings on the tanks to help identify which is which. Also you don't make any mention of using a gas regulator to control the fuel pressure to the burner, and what you would do with that as you shut down a forge. I think you're also assuming that everyone has a gas valve at their burner which is frequently not the case, as having a 90-degree shut-off valve at the tank end allows you to cut off the fuel away from the flame source in an emergency, and also allows you to depressurise the hose when you are turning off your forge. Also, in many cases, minimising the amount of metal pipework at the burner end reduces the amount of mechanical stress put through the burner mounts as well as the burner jets, as it is possible to mis-align a burner jet with too much pipework hanging off it. Why not tell us a bit about yourself and what your plans are and then everyone can chip in. Tinker Tim

-

I think you might have missed Mikey's point, Lee. He is referring to the point on the 9" x 3/4" mixing tube where it goes into the forge, just above the 4 bolts in a cross, used to retain the burner in the forge body, not the washers above the jets which affect the flow of primary air into the top of the burners. There is a gap where the burners meet the forge body and extra secondary air can get into the forge at this point and affect the fuel/air mixture and combustion. Hope that makes it clearer. Tink!

-

3D printed plastic burner experiments (photo heavy)

tinkertim replied to Another FrankenBurner's topic in Gas Forges

No. No files have been posted up. It is more a discussion so that people can get ideas and try things out themselves. I wouldn't expect AFB to post up any CAD plans or STL files as his high-efficiency burner design would rapidly appear on Ebay and Alibaba! He has posted enough pictures of his various versions and experiments so that anyone on here could have a play with a CAD package and print something out to play with. In the past, people have suggested that AFB make and sell his Vortex Inducer bodies for people to assemble into burners, but he wasn't looking to commercialise his design, more to experiment, learn and enjoy himself. I'm sure if you put together your own CAD model based on his images, and tried it out, he'd be happy to give you feedback. Tink!- 863 replies

-

3D printed plastic burner experiments (photo heavy)

tinkertim replied to Another FrankenBurner's topic in Gas Forges

Hi Jake, I don't think it does replicate a wing tip, as in these vortex inducer designs, both ends of the "wing" are attached to the inducer body. The current design has sloped vanes, and these vanes also appear to spiral inwards a little, so guiding and inducing spin to the airflow as it turns through ~90* and is accelerated down the mixing tube by the gas jet. I believe Another FrankenBurner (AFB) tried various designs for the vanes including aeroplane wing profiles, but that it didn't make that much difference compared to the width and spiral-angle of the vanes. At least that what I recall from this many-pages thread over the years. Maybe AFB will pop by and correct me, as it would be nice to hear from him again. Tink!- 863 replies

-

3D printed plastic burner experiments (photo heavy)

tinkertim replied to Another FrankenBurner's topic in Gas Forges

I use the free CAD tool Designspark 3D by RS. Powerful but surprising easy to use. I got part way through trying to make a tri-finned burner head but got a bit stuck on the profile of the blades and decided to park it until I have a bit more time to learn about "lofting". I'll 3D print myself one one day, to experiment with smaller hand-held Rose-bud type burners, and include a handle.- 863 replies

-

Glad to have you back Frank! I've still got some backburner projects to do, including a 3D-printed burner, but I need to play some more with my free CAD software, to get the spiralling aerofoil profiles how I want them, using your vortex injectors as a starting point. I'll get there......one day!

-

Advice Needed For First Propane Forge Build..Cylindrical Or Square?

tinkertim replied to MrMedieval's topic in Gas Forges

I think Mikey is referring to Insulating Fire Bricks (IFBs) that are light weight, easy to cut and drill, and have really good insulating properties. If your fire bricks are heavy, then you've got the wrong ones. They are often used for peoples first Propane forges, (which is why they are known as "Brick Pile" forges,) as you can build a square tunnel out of IFBs, which are held together with angle-iron and threaded-rod, and can get up a good heat. The downside is that IFBs are not mechanically tough, and can easily crack due to thermal cycling. There are brands (Morgan Ceramic) that are meant to be longer life, but if you seal the IFB surface with a decent flame-face coating (Plistex, Matricote, etc.) that protects the IFBs, they last much longer. I think Mikey was suggesting that you could build any shape of forge you like out of IFBs and angle-iron, and easily try out what works best for you, and maybe not need a steel shell around it. I built my first Propane forge out of IFBs so I could try out single-port and multi-port burners and see what size and shape of forge worked for me. It was only after that, that I designed and built an oval Ceramic-wool lined forge to take my multi-port burner, and that is now my go-to forge. Hope this helps, Tink! -

MrMedieval, you can do quotes, just trim out the un-needed text so you only quote exactly what is needed. The reason for this is that many users of this forum have limited bandwidth, and so minimising quotes to just the necessary text, as well as posting small images instead of large videos, helps to minimise the storage requirements on the server and aides our bandwidth-limited brethren. Regarding the use of the @"name" reference. This forum's underlying engine doesn't like the use of @"name" references and you will get asked not to use them. Hope this helps. Tink!

-

Cutting existing castable refractory to modify a forge?

tinkertim replied to Hefty's topic in Ribbon Burners

Hi Jono. IFBs are normally quite soft and can be cut with an old hacksaw blade or drilled with an old HSS drill very easily. I say old, as the IFB will blunt your best drill bits quickly. I haven't experienced using Morgan Ceramics K26 IFBs, which I believe are longest lasting you can get. Many of my generic K26 IFBs have cracked in a few uses, but with my original brick-pile forge, they were held together with lengths of angle-iron and threaded rod, so that even if they cracked they would stay together. With my later Kaowool-lined oval forge I still used IFBs for movable doors. Regarding using IFBs for NARBs, it is very easy to experiment with drill patterns, and if you start smaller, you can easily enlarge the holes with the next drill size up, maybe a few at a time, to give you finer control as you creep up on that sweet spot of flame behaviour. My first NARB had holes that were too big, so the Fuel/Air Mix (FAM) wouldn't flow fast enough, and so would burn back into the IFB itself and cause the bits of IFB between the holes (webs?) to heat up to bright glowing. Another observation that others made was that if the holes are too big, then the IR radiation given off by the walls of a hot forge can get into those holes and heat up the webs as well. Anyway, when the first design above was used in my 1st brick forge, the flame burnt back into the plenum chamber and burned there, causing the stainless-steel plenum to start glowing yellow hot! The second drill pattern (27 x 5.5mm holes) seemed to be spot on for my 3/4" burner, and would give me a good range of turn-down without burning back into the plenum, and would let me turn it up to full yellow-white heat as well. So, once I'd got a good drill pattern for my NARB, I looked into coating the flame face to protect the IFB. In the UK it is hard to get Plistex or Matricote or other well-known-in-the-USA kiln-washes, so I followed a suggestion of Dan Rotblatt and made my own from Zircopax flour and a Colloidal Silica solution, that he used as an investment coating for metal casting, as well as lining his own forges. These materials were easier for a hobbyist in the UK to find, and worked really well for me. I've coated all of the flame-facing IFB surfaces with multiple layers of this DIY kiln wash and it seems to have really protected the IFBs. I haven't had to re-make my IFB NARB yet (but then I haven't used it for many Months) but I've been very happy with my NARB solution. It is much quieter in use and uses less Propane from my testing. Sorry for the Essay, but I hope some of it is helpful. Tink! -

Cutting existing castable refractory to modify a forge?

tinkertim replied to Hefty's topic in Ribbon Burners

Either orientation. I have a blocking plug for the other. My brick-pile forge uses one port, my oval mop-pail forge uses the other. works a treat! -

Cutting existing castable refractory to modify a forge?

tinkertim replied to Hefty's topic in Ribbon Burners

I did my NARB development using a half Insulating Fire Brick (IFB) to try out combinations of hole sizes and patterns. Once I found one that worked well, I coated the flame face of the NARB with kiln-wash for protection. Works well for me, and is easy to replace. My 1st attempt would burn back into the plenum behind the IFB, but the second attempt worked really well with a 3/4" burner, and I've been using it in my oval mop-bucket-based forge ever since. Hope this helps. Tink!