-

Posts

430 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by the_sandy_creek_forge

-

When should you choose Arc Welding?

the_sandy_creek_forge replied to Glenn's topic in Welder's beginers course

Because it's what I have in the shop. I also have oxy/fuel (not that talented or patient with that) and a little mig (which I have to fiddle with every time I use it, cause it doesn't get used much unless we're doing body work). So yeh... my best reason is because it's set the dial, flip the switch and weld. -Aaron @ the SCF (loves his old lincoln buzzbox!) -

Trying to achieve a "Black Pearl" patina

the_sandy_creek_forge replied to Susan Owen's topic in Finishes for Metal

Hey Susan, Since I just finished up a project using Gilder's Paste.... I used it on some handrail and some cabinet knobs. Once it has "cured" it seems to be a pretty durable finish. I.E. it took A LOT of elbow grease to buff out the finish using a clean shop towel. How well it would hold up under continuous wear, I can't say. I still sprayed the knobs and railing with an acrylic clear just to be on the safe side. The different colors CAN be mixed, although I am not sure if they make the right combination of colors to get the effect you are looking for. Another option might be to bring a high polish on the jewelry and then bake them in the oven to draw a blue temper color. Not sure if it would be exactly what you're looking for, but definitely something different. This is a different color of bluing from what you get from, say, Birchwood Casey (sp?) or the likes. Just something to think about. -Aaron @ the SCF -

Ya know... I had a professor in college (older gentleman who simply refused to retire...) who would go on rants about things that were "new and improved." The premise being if something was NEW it hadn't yet had time to be IMPROVED as something NEW would be the first of its kind ever made! He was also a big proponent of reel mowers, spam, and typing up tests and quizes on a typewriter. He'd probably still be using a mimeograph if the school had one sitting around... Back on topic... For my files and cutting tools (lathe bits, shaper bits, non-coated drill bits) I've been using Singer sewing machine oil. I also use MMO for warding off rust, as well as the occasional squirt of WD40. -Aaron @ the SCF

-

Welding Triptic

the_sandy_creek_forge replied to bipolarandy's topic in Blacksmithing, General Discussion

Andrei, Nice turnout on the arc pictures. Did you UV filter it? "It was my hand holding a... um... welding stinger...I swear!" -Aaron @ the SCF -

I think maybe The Art of Blacksmithing by Alex W Bealer. Pg. 114. It's a heavy wooden frame, and it uses a lamination of planks as the spring. It just happens to be directly opposite the pictures of spring-pole and treadle style lathes on Pg. 115. If you don't already have the book, I suggest getting it. A good "history of blacksmithing lesson" and LOTS of pen-and-ink style illustrations (what can I say... I love pictures ) -Aaron @ the SCF P.S. I have the 1995 edition for reference purposes Edited to add: A picture of it is also on the back of the dustcover.

-

Man... it's been a while since I conversed with one of the scrap guys apparently! I caught one of them out at the gas station a few days ago and inquired about prices. Central Illinois is a bit more in line with the rest of y'all at 200 and up from there ... or maybe that should be a ... or a :mad: ? Not really sure. -Confused... er... um... Aaron @ the SCF

-

Ding! It didn't click in my head 'till I read that. Double thumbs-up approval to Thomas' advice:cool:. It'd be a bit of a jog, but WELL worth the trip. -Aaron @ the SCF

-

Erik, I agree with what Steve said above. Also can't resist to throw this in since it is in your neck of the woods. http://www.iforgeiron.com/forum/f13/meet-roy-underhill-john-deere-hammerin-2008-a-5367/ Welcome to IFI! -Aaron @ the SCF

-

Chris, Not sure how "local" your local harbor freight is... but we got our 9x20 as a "returned item." Meaning basically someone had bought it, used it once, decided they didn't like it, and brought it back (without the faceplate:( ). We were asking about details on one and the manager mentioned they had the returned one in the back. Can't remember off the top of my head, but I am pretty sure we got about 25% off because of it being returned and all (without the faceplate:( ). Otherwise just keep watching the 'bay. One might turn up sooner or later.

-

It followed me home

the_sandy_creek_forge replied to Glenn's topic in Blacksmithing, General Discussion

Good find Frosty. The best part about those lockers is that they are, for the most part, mouse resistant. Handy for storing books and welding leathers and such. -Aaron @ the SCF -

Last I heard, central Illinois places were buying for about $100-125 a ton steel. The very few places that'll still let you come in and rummage around to find what you need were selling at 15-20 cents a pound...so...$300-$400 a ton. Not bad considering I just picked up 1-20' 2.5x2.5x3/16 angle and 2-20' 1x1x1/8 angle New steel for a customers project and it cost 'bout $90. -Aaron @ the SCF

-

Welding nuts or bolts to metal

the_sandy_creek_forge replied to Glenn's topic in Welding/Fab General Discussion

Kinda carried over from the welding spatter thread. I never-seize the whole bolt, put it in place and wipe off any never-seize that will get in the way of the weld. Helps the bolt release from the nut AND keeps the spatter off of the threads. I usually just weld on two opposite flats, but have welded around the whole nut depending on the application. And ALWAYS ALWAYS ALWAYS grind off any coating that is on the nut or bolt before welding. ALWAYS. -Aaron @ the SCF -

I've used CAT brand high-temp antiseize (the copper colored type) when welding near exposed bolt threads. It's kinda pricey, but it worked great though. I like the PAM idea, I'll have to give that a try. And as far as my welding bench or welding table.... well.... their both rusty enough that, for the most part, the spatter doesn't really stick at all. When I do have to remove spatter, I have an old cold chisel that has a really acute angle to it, it works great for scraping it off. -Aaron @ the SCF

-

Hey Keith, Let me frame this with a disclaimer *I am in no way a machinist. I just happen to utilize a small lathe and a metal shaper to make jigs, dies, etc. for my blacksmithing work* I started out on the lathe with some of the cheapo brazed carbide bits from HF and a set of the cheap indexable ones from grizzly (all 3/8") Then when I got my shaper, I discovered HSS bits. I personally prefer the HSS for everything that I do now. I can get a pretty decent finish, but my tool grinding skills do need some work. One of these days I'm gonna meet with the local high-school shop teacher to get some pointers, just haven't had the time yet. Right now I grind my bits on a regular old 6 inch bench grinder and then touch them up with a medium grit pocket stone to make everything nice and smooth. Making an adjustable work-rest and setting up a dedicated grinder for grinding tooling is also on my list. I also like HSS because, If you keep an eye on ebay, you can sometimes get a large lot of gently used tooling for a decent price. -Aaron @ the SCF

-

ya know... I opened this thread thinking "this is gonna be some grisly story about someone getting smacked in the mouth with a hammer" nah.... that would go under the safety thread. Then I thought "maybe it's something about an old west blacksmith who doubled as the town dentist" nah... that would be more under blacksmith>history or something... and while my my first thought was closer than my second thought... I never expected this. All I can add is this quote (which just happens to come from your's truly) "Pauly, in the long history of bad ideas, this is right up there with the time we went down those three flights of stairs on that plastic sled that one night." -Aaron @ the SCF

-

New apprentice at The Sandy Creek Forge

the_sandy_creek_forge replied to the_sandy_creek_forge's topic in Everything Else

Thanks Mike, I downloaded "paint.net" mostly to use for working on my website design, and one of my buddies from work (I work with stock photography) came over tonight to give me some pointers. He's big into photoshop, and that was one of the first images I've doctored up on my own:) -Aaron @ the SCF -

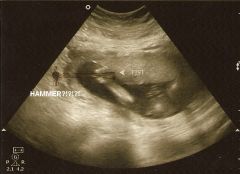

Hey all, Not sure how I've managed to not mention this here yet... but on or around May 31, 2008, the Sandy Creek Forge will be getting a new apprentice. Image #1 Image #2 This image confirms that the new apprentice is, in fact, of the male persuasion, but wasn't real sure about posting the image here, as the ultrasound tech did a most wonderful and professional job of labeling it..... Image #3-a solid fist with a nice strong grip. Image #4- The ultrasound tech almost fainted when she saw this one.... I, however, wasn't a bit surprised -Aaron @ the SCF

-

-

-

-

Hey Sam, Nice looking hammer head. As far as what it does? (and someone correct me if I am wrong on this). The sawyer would use the hammer on a COLD circular saw blade. With the correct knowledge and skill, he'd use the hammer to stretch the steel to put a certain amount of tension into the blade, this helped the blade spin "true," in other words it took the wobble out of the blade as the mill was running. There's as much of an art to it as there is to blacksmithing. My grandpa and great-uncle made a living doing many things, one of which was running sawmills. We still have the remnant of the tracks from one of the old mills, and a very much workable setworks (all the gears that run the blade and the feed). We also have the tracks and carriage off of a newer mill that we will HOPEFULLY be able to eventually set in line with the old setworks and have an operating mill again. Our solution for taking the wobble out of the blade? Speed the engine up or slow it down until the blade runs true:) I know, it's kinda cheating, but like I said, there's an art to tuning a blade and having a blade tuned by a professional isn't cheap, when a professional can be found. -Aaron @ the SCF

-

Hey all, Found the google book I was talking about earlier. It ended up being the Buffalo Forge Company and NOT the Champion (leave it to my memory....). If anyone is interested do a search on google books for "1896 illustrated general catalogue" and it should be the one at the top of the list. -Aaron @ the SCF

-

Jayco, There USED to be either a Champion or Buffalo catalog on Gogglebooks. I know I have it downloaded at home, but can't remember off the top of my head which one it is. If it's the champion catalog I'll send it along this weekend when I get a chance. If it's not, I'll send it along anyway cause it's full of all manner of neat things. I just checked googlebooks and can't seem to find it again, but it seems they've lost alot recently (over copyright issues???) anybody know what's going on with that? -Aaron @ the SCF

-

How do you earn your living?

the_sandy_creek_forge replied to larrynjr's topic in Blacksmithing, General Discussion

To make the money: Data Entry Specialist (Keywording and Captions) for the third largest stock photography company in the US. To stay sane and make a little money besides: Blacksmithing, and helping my friends/coworkers with "their" home improvement projects. -Aaron @ the SCF -

Cool YouTube cannon forging vid

the_sandy_creek_forge replied to FrogPondForge's topic in Blacksmithing, General Discussion

Wonderful vid. I especially like that "slide hammer" tool the were using to seat the rings and to open them up over the cone. I might have to make myself a set of those for using on my little cone (someday) -Aaron @ the SCF