-

Posts

430 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by the_sandy_creek_forge

-

Hey everyone. This isn't really an introduction, seeing as I've been here a while, but I didn't know where else to put it. I'm taking a bit of a sabbatical from blacksmithing. I've gotten myself tied up in too many other things at the moment and something had to get shoved to the back burner before everything went up in smoke. Unfortunately, as circumstances and conditions would have it, this something was my blacksmithing habit...er, I mean.... hobby If anybody needs me for anything, my email addy is the_sandy_creek_forge(at)yahoo(dot)com. I usually check that twice a week or so. I'm also gonna try to check into the forums now and then as time allows. In the meantime, happy smithin' to all, and I'll see y'all come springtime! -Aaron @ the SCF **Glenn: If there is a better subforum for this post, please feel free to move it accordingly**

-

A Very Satisfying Christmas Gift

the_sandy_creek_forge replied to Leland's topic in Blacksmithing, General Discussion

Very nice! If I might ask, what finish did you use on the lignum handle? Whatever it is the color made a nice, slightly subdued, complement to the copper ferule. I might have to file that combination away for future use -Aaron @ the SCF -

Thanks Ironrose, I'll look into those. Right now I'm starting simple, couple of gun pouches, some axe/hatchet/'hawk pouches, kinda of basic cut it, stitch it, rivet it, and maybe stamp some initials on it type of stuff. Thanks again all, -Aaron @ the SCF

-

Hey everyone, Since the baby arrived back in May, and the wife shifted over to a funky split 2nd/3rd shift, I haven't had a lot of shop time outside of about one day a weekend. In the meantime I'd been looking for a hobby (cause I just NEED another hobby:D ) that I could work on in the comfort of my living room and/or garage. I'd picked up some leather straps and buckles a while back to make a replacement set for some old climbing spikes we have and thought to myself "Hey, this is kinda fun". Forward a couple months to Christmas time and Tandy leather is having a pretty decent after Christmas sale. Needless to say, I found my new hobby:) While the sale prices were reasonable at Tandy, their everyday price is, in my opinion, a little bit high. I was wondering if anyone here had any input on other sources/suppliers of leather goods (quality, price, customer service, etc.) It seems like at one time there were some guys here on IForgeIron that were the buckskinner/rendezvous types. If you're out there your input would be very much appreciated. I figured I'd look here for advice first, instead of just trusting the user reviews on some random website. Thanks everyone, -Aaron @ the SCF (who today learned this lesson: NEVER tell your 5 year old daughter that the furry thing right next to her is a reindeer skin.... especially 2 days after Christmas..... )

-

I've always preferred "frugal" Gonna miss ya here Thomas. I'm sure I'll see ya around on some side of the street or another sooner or later. -Aaron @ the SCF

-

From American Railway Engineering Association's Specifications for Soft-Steel Track Spikes. Original document, 1926, revised last in 1968 Courtesy of ThomasPowers from a post back in January. Page 5-2-2 Section 11. Marking. A letter or brand indicating the manufacturer shall be pressed on the head of each spike while it is being formed. When copper is specified, the letters "CU" shall be added. Page 5-2-3: Specifications for high carbon steel track spikes 1968. Carbon not greater than 0.30%, nor greater than 0.20% c opper. Page 5-2-4. Section 6a. Bending properties: The body of a full size finished spike shall stand being bent cold through 120 degrees around a pin, the diameter of which is not greater than the thickness of the spike without cracking on the outside portion of the bent portion. Page 5-2-5 Section 11. Marking: A letter or brand indicating manufacturer and also the letters "HC" indicating high carbon, shall be pressed on the head of each spike while it is being formed. When copper is specified, the letters "CU" shall be added." Here -Aaron @ the SCF P.S. I know, that still doesn't answer the MC question.... :D

-

Picket heater?? Yes to what Steve said. Even the DIY type ceramics people I've dealt with in the past (the types that mix their own clay and glazes) tend to go for store bought when it comes to kiln firing. -Aaron @ the SCF

-

Babco 160 vice repairs

the_sandy_creek_forge replied to lonestarwelder's topic in Blacksmithing, General Discussion

Hi lonestar, Try here for a replacement nut. McMaster-Carr (usual disclaimers) Try searching under "acme threaded nut" **for some reason if you just search "acme nut" it only brings up the precision threaded ones ???** You'll need to know size and threads per inch. It looks like the stripped out nut is cast iron, so someone else will have to offer advice on how best to join a new steel nut to the cast iron support. Oh, and next time don't let the gorilla tighten up the work in the vise for you. -Aaron @ the SCF ** photographic tip: if you want to take a close-up picture of something, take one giant step back and then use the zoom function (if so equipped) to get a closer shot. Many low end digital cameras aren't very good at focusing at distances closer than maybe 2 feet (my kodak, for example, isn't any good till you get to 3 feet or so). There's a term for this, "Macro" maybe, I can't remember for sure. ** -

Gas welding real wi

the_sandy_creek_forge replied to Dave Leppo's topic in Welding/Fab General Discussion

Thinking out loud here, but would it be possible to raise the piece to welding temperature with the torch on a neutral flame and just kind of "forge weld" it sans "forge"?? Any thoughts Jr. or anyone else?? Thanks, -Aaron @ the SCF -

After some creative googling, I got this. Not much, but some info. Seems it might be rare because (according to this site) very few were made, and were made for a very special purpose. "The Boss" power hammer -Aaron @ the SCF Edit: found a few more hits. not much though. http://omaha.craigslist.org/tls/932635771.html http://www.spaco.org/pow.htm More or less pictures. From what I gathered with a quick look, Novelty Iron Works seems to be a late 18th/early19th century do-all, cast-all, make-all if it will sell type of operation.

-

Does the original switch look like this?? G8989 Toggle Safety Switch if it's the drill press I am thinking of, that should be a near direct replacement. might want to double check the mounting hole size. P.S. breaker shouldn't be tripping when you turn it off, as that means there is a short somewhere I would think. -Aaron @ the SCF

-

Air Cylinder Source Needed

the_sandy_creek_forge replied to Woodeye's topic in Power Hammers, Treadle Hammers, Olivers

Woodeye, I know you spec'd a pneumatic cylinder in your post, but have you considered using a hydraulic instead. Most hydraulic cylinders are rated at 2000+ psi, so they should be able to handle a few hundred psi of air pressure easily. You might need to consider some kind of oiler set-up to keep the seals on internals in good shape. Also I have found that, generally, hydraulic cylinders of a given size have larger ports than a similar sized air cylinder, equaling more airflow. Haven't checked the price on pneumatics, but a hydraulic cylinder to your spec'd size runs about $100 at Tractor Supply. Just a few thoughts, as I am planning on using a hydraulic cylinder in place of a pneumatic if I ever get around to building an air hammer. -Aaron @ the SCF -

If what you're photographing is small enough, try doing a google search on "homemade light box" Looks like a fun little winter weekend project ( 1 hr. to build a decent light box, rest of the weekend to use it taking pictures of everything in sight ) (Day job) I work with stock photography, and had wondered how the photo editors were getting such natural looking "cutout" images of objects. When I asked one of the photo-eds, she cued me into these setups. I was surprised to find that the it was not some nifty trick in the latest edition of PhotoChop, but that it actually originated from the photographer's set-up! -Aaron @ the SCF

-

Blacksmithing and the Economy

the_sandy_creek_forge replied to Archie Zietman's topic in Blacksmithing, General Discussion

Thankfully blacksmithing is still a sideline work for me. I wrote up one proposal this summer for a set of end tables. Real simple design (4) 3/4" square legs with (4) 1/2" square spanners. Lightly textured. They were supplying the (handcrafted in Mexico) hammered copper tops, so this was literally JUST the legs. Customer turned the project down based on a materials quote without even seeing my labor quote And these customers were by no means not in a position to throw a little money around. Seems like everyone in central Illinois is buckling down, even those who really have no need to. Can't say I blame them. -

Are you Left or Right???

the_sandy_creek_forge replied to gpworks's topic in Blacksmithing, General Discussion

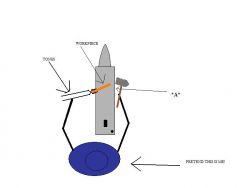

I am right handed (hammer right, hold w/ left). I usually end up with the horn pointing away from me. Please reference attached, um, diagram. My anvil has a fair bit of a sway-back/saddle-back to it. Therefore the area of my anvil that is the flattest and least likely to introduce unnecessary curves to a workpiece is perpendicular to the anvil's main axis of symmetry (i.e. across the face). Add to this that at area *A* I have a fairly well rounded edge that I use as a fuller for drawing out and it only makes sense for me to stand where I do, I think. Your mileage may vary. -Aaron @ the SCF (and yes, I am one of those people who does most of my general drawing out with half-face blows over the edge of the anvil) -

-

a slightly rusted steel topped table. regular old chalkboard chalk (keeping it sharp). oh, and keep the five year old offspring away from the drawing or you might end up with extra spindles or a smiley face right in the middle of your beautiful art deco railing -Aaron @ the SCF

-

Flat Belt and Belt Lacing

the_sandy_creek_forge replied to the_sandy_creek_forge's topic in Machinery General Discussions

Thanks for the lead Thomas. I managed to find a .PDF format of it online. Not as handy as the book, but still alright for reference purposes. Got to looking through it, and it appears to be a handy little book to have. Might have to look up a copy someday. Thanks, -Aaron @ the SCF -

Flat Belt and Belt Lacing

the_sandy_creek_forge replied to the_sandy_creek_forge's topic in Machinery General Discussions

Thanks for the replies guys. I hadn't even though of baler belts and fasteners for a lead. This all led me on a little search, and I found a local place that can order this Flexco Alligator Lacing for me. Best part is, no press/lacer needed, just a flat surface, a good square, and a light hammer. Thanks again! -Aaron @ the SCF -

Does anyone know about...

the_sandy_creek_forge replied to Sam Thompson's topic in Blacksmithing, General Discussion

P.S. if anyone needs me I will be sitting right here, staring at that patent, and scratching my head for the next few days straight... -Aaron @ the SCF -

Does anyone know about...

the_sandy_creek_forge replied to Sam Thompson's topic in Blacksmithing, General Discussion

BINGO! Patent Number 1196838 Issue date Sept. 1916 and.... are you all ready for this.... the patent is for a device called a "Combination bench lathe and drill press." Apparently, with all of the attachments, this thing was an anvil, a vise, a pipe vise, a grinder, a lathe, a drill press, and maybe something else depending on what was attached and which side was considered to be the "top" or the "base"... human ingenuity at its best... maybe.... Patent from google -Aaron @ the SCF -

Hey everyone, Looking for some input on flat belts and lacing. After pricing out leather belts from McMaster Carr, I am thinking that it will be less expensive to go to Tandy and just buy a whole side of leather and cut my own belts. I have access to a leather belt/lacing cutter so I should be able to cut nice even belts. Anyone ever cut their own or have any thoughts on the matter? The second thought is lacing. Given that the drill press these belts are for (see bellow) requires two belts per spindle plus one belt to drive the main shaft (yep. one machine, seven belts!) it will obviously be worthwhile for me to be able to make and lace the belts myself. So, next step was finding a lacer... and then I saw some prices... . While I'm not necessarily Cheap, I do try to be Frugal. From what I can tell looking at pictures of lacers, they seem to just be a kind of specialized and glorified press to shove the lacings into the belt. Would it be possible to make a set of dies for a 3 ton arbor press that would do the same thing? I have the shaper, so cutting a die profile wouldn't be too hard if necessary, just a little time consuming. Any thoughts on this? Thanks in advance for any thoughts and help. -Aaron @ the SCF

-

Around here (Central Illinois) usual going price at auctions is between 50 and 100 dollars, depending on condition and number of antique collectors who happen to be at the auction. So that price sounds about right. My personal opinion: being able to sharpen (axes, knives, hatchets, mower blades, etc.) on a natural stone is worth that price. The two I have (one complete with metal tube frame, one just the wheel and mounting hardware for a wooden frame) are both slightly out of round. Since they are run so slow it really doesn't affect my using them that much. Also consider a 14" grinding wheel, Aluminum Oxide, from Mcmaster Carr will run you in the 100 dollar range, and it is NOT a natural stone wheel. -Aaron @ the SCF