-

Posts

9,756 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Daswulf

-

-

Thank you for the knowledge Charles, I appreciate it. I'll still be sending a couple hammers to rthibeau. but i may work on a couple others. I have a good size stock to work on some hardy hole tools so a bottom fuller sounds like a project some time. the anvil horn will work fine as well.

-

Half round faced hammers are nice for drawing over the horn. Take a 2-2 1/2# double jack and gring one face to a smothe 1/2 circle pein. Mine are 3# one strait and one cross. Used with the horn they move metal well, but dont make drastic divits. i'm with Frosty I tend to stand infront of the horn with a strait pein and the stock perpendicular to the anvil for drawing operations

I gave it a go this last time but i think my hammers arnt faced properly and i Was hitting too deep. it worked tho. I'm getting 2 of my hammers out to rt to reface. other then that i'm going to give a couple a go as well

but i thank you for the tip Charles and i'll keep at it. cant wait to try out some hammers refaced by someone in the know.

but i thank you for the tip Charles and i'll keep at it. cant wait to try out some hammers refaced by someone in the know. -

Yeah Seek. Point the tong bits at each other and overlap them like they would make a solid piece. Sort of like mirror matching em. People that are good could eyeball them bit I'm still learning so it helps.

-

I'd wade through 3 feet of termites for that kind of score. Nice!

-

A tip I saw on getting the bits the same length is to check them by sort of fitting them together like they are two halves when they are close to done, that way if they are even there won't be more space on one from the other. The will fit together close. And you can modify if you need to. Hope that made sense. It helped me get the bits closer to the same length.

-

Definitely my MIG. Then my forge. In that order, mig helped me make the forge.

-

the oval one i'll give a shot at a bending tool. the oblong one i might use as a more crisp anvil face as needed until i find a better use. and the other i dunno. maybe give them a shot at helping with box jaw tongs when i try a set, or collars when i'm ready. what ever they speak to me as. or if they could help out someone who has a purpose.

I really like hearing what peoples ideas are on things i'm not sure of. it gives me ideas if not someone saying hey! i've been looking for That thing.

I really like hearing what peoples ideas are on things i'm not sure of. it gives me ideas if not someone saying hey! i've been looking for That thing. -

it fits great( tight) actually. i have other tools that that is a great idea for tho.

-

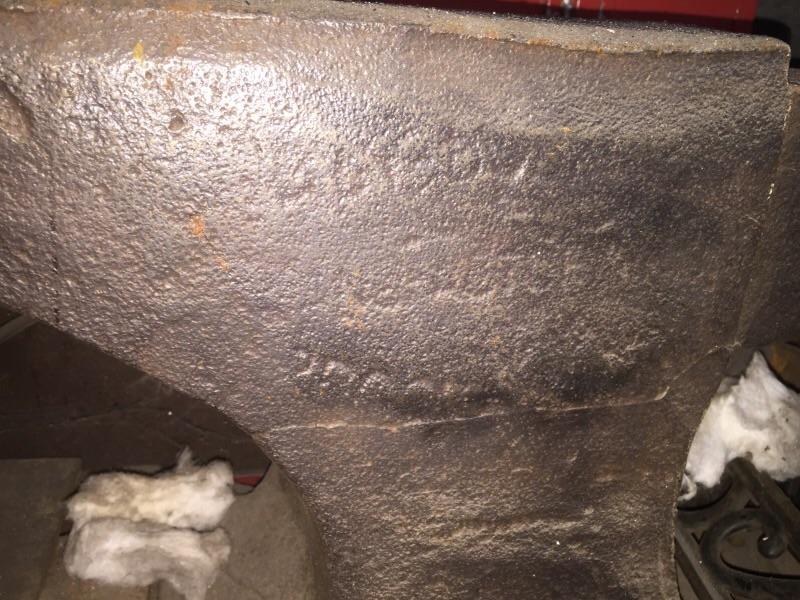

Ok so while I was attempting a nail header and failing I worked on my first hot cut hardy. Here is what I came up with. It was 3/4" by 1 1/2" stock. My hardy hole is about 7/8 if I remember right. I actually haven't tried it yet and that's the best test. But I finished it up at the end of the night.

-

*smiles* Frosty Thanks. i'll keep at it too. i have more things to do so i have to diversify. Yes, i will keep making tongs till i get it to where i can make them in no time. I Am very humbled and inspired by any praise I've gotten on my progress. it cant end there

I have to keep on going. you guys are great. if you guys arn't inspirational, i don't know what is. A very meaningful Thank You. i'm sure i'll make ugly useless stuff. i just did tonight but thats the learning process and i will keep going till i improve.

I have to keep on going. you guys are great. if you guys arn't inspirational, i don't know what is. A very meaningful Thank You. i'm sure i'll make ugly useless stuff. i just did tonight but thats the learning process and i will keep going till i improve. -

I do plan to eventually make custom autobody hammers and tools. with experience in the field I think i could come up with a bunch of designs. i already have been making custom dent picking rods. not so much for dent wizards but for practical regular repair.

-

Thanks Mac.

Those look and sound to be good books. When my funds improve soon I'll get em. From the site looks like the third book has some techniques I'd love to try out.

Ive really enjoyed working and improving on these.

-

Well done on the tongs. Keep at it and you'll have a nice arsenal of tongs to easily handle and tackle your future projects.

Thank you TechnicusJoe. I really appreciate the videos you've done. They are very helpful and well made.

-

i'm in no position to argue the point. so i'd have to let you guys argue the point.

-

-

i do notice mine moves around on me a bit but it dosnt affect my work, just means i need a heavier base or to bolt it down but i dont have my area set up how i want it yet to bolt anything down. no biggy, I can always nudge the stand back where it belongs for now. hey i'm just starting out. i need the exercise

and again it's not the size of the anvil, it's how you use it. for now, for me i'm happy with what i got. and with these hardy tools, i'll find a use for them eventually or pass them on to the next person that has an idea for em.

and again it's not the size of the anvil, it's how you use it. for now, for me i'm happy with what i got. and with these hardy tools, i'll find a use for them eventually or pass them on to the next person that has an idea for em. -

I'm not familiar with the term, "tankers bar."

you walk into the bar and they tank you for coming.

-

I am impressed with how fast you are progressing.

Thanks much. i'm nowhere i want to be yet but i'm a quick learner and a visual learner. I respect constructive criticism and try to learn from mistakes that even i can see let alone what more experienced people see. I learned early off that you get nowhere without trying to always improve. I don't mean to sound vein at all. but yeah I actually like ideas from experienced people that can help me get better at what i like to do, and they have all but "if not" perfected.

There are alot of people out there that learned the hard way and tho I seem to Have to do that on occasion, they are very inspirational and i value the fact that they are willing to take the time to help others on their path.

Really, Thank you guys! You have been, and i'm sure you will continue to be, a real great help to me and countless others. ( In case you guys don't get that gratitude you deserve once in a while

)

) Keep on hammering!

-

Ok the other night I completed a third pair of tongs. Didn't get pictures then as I was also doing an oil change and another repair in between. Got pics tonight. I changed the bit style and it didn't end up as I was wanting but I feel I got the reins "better". Newest tongs have the longer flat bit. I did chisel a cross hatch in them but after thinking figured that it wouldn't be of use. And did give it a sloppy strike with 1/4" stock before I realized that I hadn't wanted to. Ugh the price of being distracted from what your trying to do. The bits are off but I feel I improved on the basic form. I will continue the quest as well as others to improve my hammering.

-

Even with the big boys, you use what work for the job. That's a good lesson.

-

haha i'm not very envious, but a larger anvill then a 100# would be nice. i'm in no hurry tho. and i like the post vices i have so far. no big deal at least i have pretty good stuff i scrounged to start with. i'm happy so far

tho i do want to improve my skills And equipment. skills/ knowledge are first.

-

Those are good ideas on that one. I really had no clue other then they look like the one half of box jaw tongs. Thank you for the ideas. i never would have thought of collars.

Never know, thats why it's nice to get others opinions, guesses, ideas.

On the longer piece, i had some ideas on uses but i'd hate to modify such a nice large piece only to find a better use for it later(has happened) when i could have made a simpler, smaller, solution earlier off.

-

The lug on the long side of the oval appears to be a hook to hold the end of the workpiece when you start to pull it around.

that is what that appears to be.

-

Thank you for clearing it up for me. As others have said there is a lot of info on the Internet and a lot of it can be generalized or just partial info.

Those are probably pretty large anvils.

I also thought about it and am thinking it would be hard to guess a repurposing for these without knowing what I'd be doing. I'd settle for any ideas tho.

there are things to be learned through everything.

First cut off hardy.

in Hot Cuts, Anvil devils, metal cutting on the anvil.

Posted

Thanks Noobrider. The great thing about blacksmithing is being Able to make tools for the job. I will try it and see how it works, and if it can be better I will modify it. If i need a different one, I can Make it.