-

Posts

9,756 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Daswulf

-

-

Thanks for the heads up Frosty. I'm asking more questions on them now. I'm not in a hurry for anything and this was way more then I was going to need. But "if" it's a deal I'd take it. I just ask around about stuff and sometimes I get a hit. If I don't have anything by the time I'm ready for it I will definitely call around and find a source.

-

Around here that would be a good price; just remember that they will need a long slow drying out period at low heat---days to weeks would be best to allow the water to get out of them. Helps prevent them cracking the first time you go for a forging heat with them.

Thanks Thomas that's a good point. Looks like they have been out in the elements for a while.

If it was used for a kiln it may not stand up to forge heat most bricks are rated to a certain heat, this is what a dealer told me when I contacted them

I'd never heard that but it's something I'll look in to.

Edit: I looked around online and I don't think I'll have any problems with em for how I would be using them.

-

I've been looking for some fire brick on the cheap and a friend of mine said his mom had some. Well she has a lot and wants to get rid of all of them. I finally got sent a few pictures.

Is .50 cents a brick a good price for used fire brick? I believe it was used for a pottery kiln.

I could probably wheel and deal on a bulk price but that's where we are at right now.

-

Best advice I could give you is to get in the yellow pages or online and search for some and give em a call and ask. Can't hurt.

-

So one of those pieces on the top rotates a shaft that goes down through the threaded section?

Or does just the bottom piece rotate so it can remain stationary as the threaded part advances?

the top turn handle rotates an inner shaft and the lower part that holds the "bit" and the "wheel" at the top rotates the threaded part that lowers it.

-

Punch was used to remove rivets on a sickle bar.

wouldn't it need a hole at the bottom for the rivet to exit?

As you can't rotate the end separately from advancing it---it is NOT a drill set up

the end does rotate separate from advancing it.

-

Had picked this hand operated drill press at an auction. Looked interesting. Only thing is it seems to have a punch in it and I don't see how it would get changed out. Looks like it would mount to a table or something. The wheel lowers it and the handle turns the bit. Unless someone changed it for a single purpose or just jammed that punch in there, I don't really see the need for the punch in a drill press. Any thoughts?

-

Leave the chips and use it. Looks like a good functional anvil. Others can tell you more but get forging on it and you'll learn what you need and don't need, and how it works for you. My one anvil had a really bad edge on it and I cleaned up and welded up one side. If I had been reading on here I would have left it alone. It has held up so far but hey. Just get using the sucker. Anvil dosnt need to be pretty to work.

-

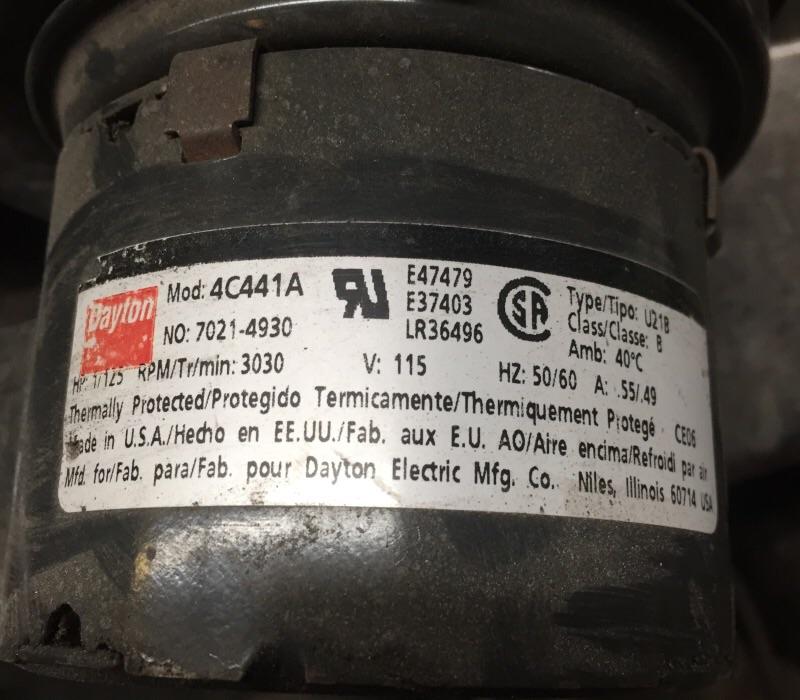

A friend of mine gave me this Dayton blower. It's really quiet even when on full. Only thing is it is smaller. But it blows perfect for my brake rotor forge. The outlet is 2" diameter and so is my pipe diameter so it fits it perfectly. They probably make larger ones as they are a well known maker but they may be big money. I was lucky to have scored it for free. I had the plate to restrict air flow until I bought a variable speed switch. But that's what I use and it's super quiet.

-

Alright, so I didn't make it too far this time around. Here's what I have been up to: I got all of my money stolen and had to settle down in Pittsburgh and work and get money. I'm living here for a while it looks like. It's not all bad though because I fell in love with a girl here who is getting me a welding job (her step dad owns a shop) which will fund my new shop here. Basically she is re-domesticating me lol. I'm doing odd jobs to make ends meet until this new job pans out. If anyone knows any smiths local to Pittsburgh and could point me in the right direction, I would appreciate it! I'll be looking into PABA soon too. Life works out in strange ways sometime.

I'd invite you out if you're not too busy. I'd be up for some help learning a bit and got some cold ones to share. I'm about 45 minutes south of Pittsburgh.

-

Nice score at the scrap yard! Way to save that great equipment from being turned into car rotors in china!

-

Thanks Glenn. Good advice. I won't be able to fire up the forge this weekend so if I can get ahold of some clay I'll try that.

Charles, I'm not struggling, I'm getting it wrong with ease.

-

I have a bit smaller pair like that. Now I know

they are handy pliers anyway.

they are handy pliers anyway. -

Didn't have a jackhammer bit, but ya can't beat a good design.

-

Lol after 12 tries I had to try something.

-

-

Could have drilled it out to reduce the weight, but that's just an uneducated guess. :)

-

True Glenn. I guess the main thing is making the dome and getting the hour glass hole shape and size correct. I'll dig around my scrap and get a piece of plate. I'm not discouraged, I'm itching to get it right so as soon as I get the chance I'll be back at it.

Forbidden of course.

sorry Frosty. I always like to hear what you have to say.

-

So I tried to make one the other night and it can be reworked for larger nails but I failed it at what I was trying because I drilled the hole first and made it too big. So when I drifted it with the nail size I couldn't get it to grip right. I'll fix it and try again with larger stock.

Second was tonight. I decided to sort of document the progression seeing as how I wanted to try it from a rr spike so I made one at each stage of the process to show how and the practice didn't hurt.

so I did end up with a crack in the first one I " spooned" out. So I made another. I actually used the handle of a post hammer locked in the post vice to dimple this guy for the pipe size.

so I did end up with a crack in the first one I " spooned" out. So I made another. I actually used the handle of a post hammer locked in the post vice to dimple this guy for the pipe size. This one I drifted crooked, and I was having issues with as well with My sizing of the stock.

These were issues on my end. And I will fix them and continue to improve.

-

sorry, the last pic is the parent material..

-

-

yeah that would be.

-

If it works and it's easy and your not taking away from someone it aint cheatn Charles. we call that working smart not hard.

-

It's mystery metal. And yeah it it dosn't hold up i'll make one from truck axle and see how it holds up.

Fair price on fire brick

in Everything Else

Posted

Thanks Charlotte. Good info to know. For the most part it would be fine as my initial idea was for a brick forge for coal. I Was mainly concerned about the brick I'd be using closest to the fire. Tho I had thought with excess brick I may be able to have some for other future projects. I'll see what I can find out from her and go from there.