-

Posts

922 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by keykeeper

-

From the album: Tools

Bottom View of Champion #400 firepot, no tuyere -

From the album: Tools

Champion #400 Whirlwind Firepot, no tuyere -

From the album: Tools

Shop blower with electric motor. -

tuyere.........

-

Not only does Federal Law trump state and local laws, but a person can be prosecuted for the same instant offense in both jurisdictions.Double jeopardy does not apply, as they are separate jurisdictions. If I'm not mistaken. Not worth chancing it, IMHO.

-

Frosty, I like the design, especially for the ease by which the chamber can be reconfigured. How efficient do you think this forge will be? If I am thinking right, and I'm sure other's here will correct me if I am wrong, aren't the brick type forges less efficient to heat to forging temps? Not knocking your design, as I think it is brilliant, just asking questions for my own good. I'm planning on building a propane forge in the near future. Just trying to do my homework. I think this forge is a great take on others I've seen using bricks as the "shell". -aaron c.

-

They were stabled at our local fairgrounds once a couple years ago. They were driving the team at a festival/parade in the next county over. I got to walk around and ask questions of the folks that handle them. I'm sure they have a staff farrier that travels with them. There were a total of 12 horses I think in the "hitch". The hitch is what they call the team, wagon, dalmation, etc. as a whole. They had three tractor trailers that move them around from place to place. That includes all the equipment that they bring. They also had a passenger van to shuttle staff around. My wife and I went out and watched them grooming and feeding them. What an operation. The staff stayed in a local hotel. They also contracted with local law enforcement folks to provide security at night to protect the horses when everyone else was away. I heard someone say that the three trailers and equipment were worth about $3 million. One of the ladies working for the hitch told me there were 5 different hitches nationwide. Google budweiser clydesdales, there is plenty of info on the horses at one of there corporation sites. -aaron c.

-

Solid anvils that are forged will have a steel top plate and wrought body, usually. Generally very good, unless the top plate is separated or missing. Cast steel anvils are generally very good, and you don't have to worry about separation of the top plate from the body, as it's all one piece, generally. CAST IRON ASO's (anvil shaped objects) are what to watch out for. Not worth much, IMO.

-

Thanks, I'll have to make one of these "spike bolster plates". I can think of several instances where smoothing and flattening the head would be useful. Thanks again.

-

Very creative and clever use of a spike. Sometimes the best gifts can't be bought. I'm sure your parents loved it. Did you flatten the top of the head before epoxy-ing it? and if so, how? -aaron c.

-

Dave, Spark testing is using a grinder or grinding wheel to test the carbon content of unknown steel. By comparing the spark patterns, you can relatively assume certain qualities of the steel. Do a search on this site and the net and you should find several references to it. I know there was a thread on here a while back discussing it. Also, there is other references on the net, some with pictures, that show spark patterns. Not an exact science, but lets one know within certain limits what kind of steel you are using, or have. By the way, nice website you and the family have, very well set up. -aaron c. edit: heres a link to a blueprint on the subject BP0020 Spark Testing*-*I Forge Iron There's also a nice little chart available here http://www.saltforkcraftsmen.org/Pdf%20flies/Saltfork%20Craftsmen%20march%202007.pdf but you have to scroll down to near the end of the newsletter. hope this helps ya.

-

Same here, cool video and hammer, Jr. Now I know what to look for in my travels. One like that would be perfect for me and my space limited shop. Thanks for the video.

-

blacksmithing/harley davidson

keykeeper replied to hdwarner's topic in Blacksmithing, General Discussion

hdwarner: You can see more of his motorcycle part engravings at Engraving by Christopher Malouf but be advised some of the pics won't come up, he's working to revamp his website. I'll tell him you liked the shift linkage.;) -

spreep: Maybe you should post in the tailgaiting section of the site. Wouldn't hurt to read the rules posted at the beginning of the threads as a sticky note, either. People can't be serious about their interest if there are NO details, and NO price stated. Also, I hope this isn't an attempt to get a price guideline for your anvils and swage block. Are you a blacksmith by chance, or an antique-r? On second thought, I'm serious, I'll give you $20.00 for the lot, you pay the shipping. Just kidding.;)

-

BAH....DUMPH.....BUMMP. (Sorry, Couldn't resist.)

-

blacksmithing/harley davidson

keykeeper replied to hdwarner's topic in Blacksmithing, General Discussion

Ok, here it is. Used with permission of owner/author C.D. Malouf, Engraver -

What have you got lurking in your backyard?

keykeeper replied to John B's topic in Metal Sculpture & Carvings

20+ deer. Is that all? I can hit that many with my truck in one evening, if'n I want to. The new state motto here should be "Deer Heaven, West Virginia" instead of "Almost Heaven". If I'm out in my shop after dark, they walk up and see what I'm doing in there. And I live IN town. -aaron c. -

I would say about four 55 gallon drums would hold a ton, depending on how tight it's packed in them. Five for sure. I don't know the measurements for a ton cubic-ly speaking, but I would use drums with lids on them. They would keep it dry and clean. As long as the coal is dry to begin with. Easily moved with a heavy dolly wherever you would need them. Or just roll them with a little help, as long as the lids are secure. When you get a new shop, then build a new bin to hold it all there. I'm sure other more experienced smiths will chime in from their experiences. Just my .02 worth. -aaron

-

blacksmithing/harley davidson

keykeeper replied to hdwarner's topic in Blacksmithing, General Discussion

Re: Shift Linkages and Fabrication I have a friend that fabbed a shift linkage from stainless hexagonal (I think) stock. I believe he also engraved the flats. Then he twisted it, if I'm not mistaken. Just some ideas for you. I'll try to get a photo from him to post. -

Beautiful work, Jose. Sometimes it's the small things that make the biggest difference in improving a persons quality of life. Ya did good. -aaron c.

-

Richard, I will have to scan some pages from the 1908 catalog also. COMPLETE blacksmithing setups for less than $100. Wish I could go back in time. -aaron c.

-

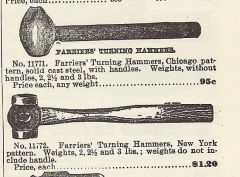

Well, I'll let everyone read the catalog selection for themself. Looks like farriers' Turning Hammer, Chicago pattern, to me.:cool:

-

-

Looks like one of the Hay Budden anvils made for one of the hardware companies as detailed in Anvils In America, p.288-289 By those pics it looks like it the hardware company name (note what looks like "CO."), then "SOLID WROUGHT" (note the ".UGHT) then Warranted, similar to some of those pictured in the book. Shape matches those in AIA for those also. That would date it late 1890's-early 1900's. -aaron c.