-

Posts

2,679 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by arkie

-

I've learned a lot about annuli in this conversation, but what I learned most is that I never want to be in one with you guys! LOL

-

Jeep & Willy's & Lovers of old vehicles

arkie replied to Irondragon Forge ClayWorks's topic in Everything Else

I can guarantee that "blowing the soot out" works. Every time he did that, the old Cheby purred like a kitten. We got a new Cheby with the 283 V-8 (back in the early '60s). Ran like a turpentined cat. It got a bit sluggish one time (Dad was burning the cheapest, low octane gas he could buy...) so I took it out one Saturday nite on a date and "blew the soot out". What I actually did was blow a HUGE hole in the muffler!! When I came home and pulled in the carport, the car sounded like a NASCAR racer at Daytona! I told my Dad it just had a big backfire...I don't really know if I got away with that or not......... -

Probably 3 or 4 ea. 1/2" or larger rods or bars...scrap will work. I used old rebar. Angle iron, about any scrap you have. Make them any length, just so that they are a few inches at least out of the electrolyte water. Be sure to use the washing soda, not baking soda for the mix. I would use about 1/4 cup to a gallon of water...there are all kinds of recipies out there of the ratios to use. Some use only a few tablespoons per gallon.

-

Jeep & Willy's & Lovers of old vehicles

arkie replied to Irondragon Forge ClayWorks's topic in Everything Else

You need to get that thing out on the highway and do as my Dad often said when the car was balking..."I gotta go blow the soot out of the xxxx thing" LOL -

My explanation of an annulus was in the context of the oil and gas industry. The other explanations and definitions are very informative also, thanks guys for adding the info. George, your explanations reminded me of my high school plane geometry class. Our teacher bristled at the terms "almost round" or "almost square". His take on it was that the object is either round or square, but the "almost" description was invalid. Hard for a high school mind to wrap around that.....LOL

-

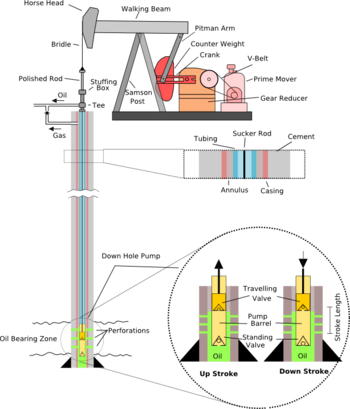

An "annulus" is not a seal. Annulus is the space between any number of sections of tubular strings in the borehole. It can be the space between the surface casing and the downhole casing string(s), it can be the space between a tubing string and casing, or it can be all the spaces between several casing strings and tubing. You might have been thinking of packers or cement plugs. Packers are temporary or permanent mechanical devices that seal off portions of tubular strings (such as tubing and casing) from others and prevent movement of fluids past desired parts of the borehole. Cement plugs are permanent placements of cement to isolate portions of the borehole from the surface or other casing strings.

-

Randy, the video I was searching for had the smiths seated at a workbench and anvil, forging smaller chain links which were probably only 2"-3" long. It may have been one that had been removed. It had much better, close-up resolution.

-

Purple Bullet you are right on. The polish rod, usually chrome plated for low friction, is the first and uppermost joint in the pump string on an oil pump. It moves up and down through the stuffing box on top of the tubing string, which seals and lubricates the polish rod. Sucker rods are the next joint(s) of the pump string below the polish rod all the way down to the bottom hole pump. Polish rods are smooth and shiny, sucker rods are not. Wiki photo attached...might have to be zoomed in to see details.

-

What did you do in the shop today?

arkie replied to Mark Ling's topic in Blacksmithing, General Discussion

bluerooster, you're welcome -

I couldn't find the old video of the old blacksmiths using a chain making tool similar to the mystery tool, but I did find one by Joey van der Steeg (Technicus Joe, a member here). It doesn't have a foot, but fits in the hardie hole. Maybe someone can find the old b/w videos of the chainmakers.

-

On a more serious note (although I better liked the other ideas, they were a hoot....!), I have seen items like that used by chain makers. After making the first weld on the anvil, the chain link is draped over the "hook" and further hammered to complete the weld and shape. I made one like this and it works pretty well. I used a large square bar and forged the hook shape in it.

-

I guess my secret is out of the closet...I'm an exhibitionist, LOL I have to be careful when forge welding, the flying borax can be devastating.

-

For working in the heat, I simply wear a wide Terry cloth tennis sweat band. It gets soaked, I just put on another, dry one. In particular, when the sweat starts running down my hammer arm, I also put a tennis sweat band on the wrist of my hammer arm. Had a hammer slide completely out of my wet hand once...flew about 10 feet...not good!

-

Thomas, I hear you about the adaptation from different climes. We went on a once-in-a-lifetime vacation to the Bahamas for a week. Great weather, but on about the third day a rogue cold front from the States blew through! Temps dropped into the 40's and we about froze our fannies... only had shorts and T-shirts to wear! The locals were worse off...I don't think there was a coat or sweater on the island!

-

What did you do in the shop today?

arkie replied to Mark Ling's topic in Blacksmithing, General Discussion

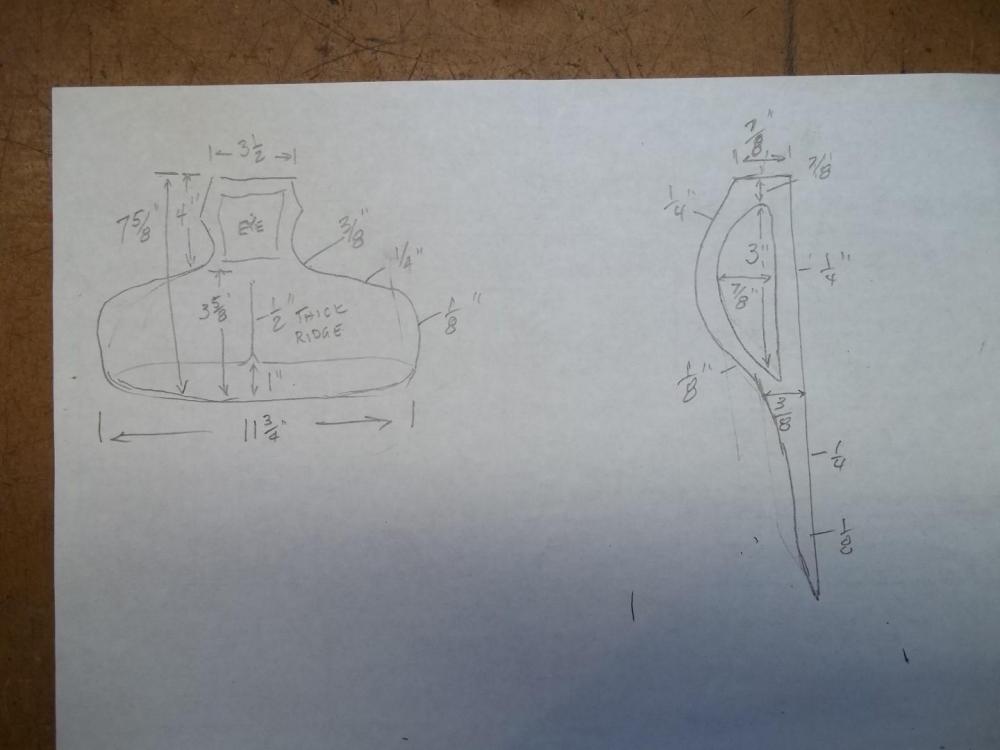

Bluerooster, I have hanging in my shop an old hewing axe head made by the American Axe and Tool Co. It's pitted from probably lying in the dirt for several years, but the photos may be of value to you if you venture into making a hewing axe. The two photos of the axe head show the profile and detail of the shape. The sketch has dimensions that may be hard to read...I scaled the photos down considerably for posting. If the dimensions are too hard to read, I can send you a larger resolution photo by PM. Good luck making one. -

You just repeated what a couple of other folks have said the function was...didn't you read the thread? And...the "font" or formatting of your text is really bad and hard to read. Try to remove the dark background and just use plain, normal text in the future.

-

What did you do in the shop today?

arkie replied to Mark Ling's topic in Blacksmithing, General Discussion

Your trick of using parts from two squares is brilliant!! Quick and easy, plus it keeps the square feature on both sides, not what you have with big calipers. -

light form forge to bright

arkie replied to alderhardtironworks's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Sorry to inform you, but those won't help a bit in filtering the IR from forging...wrong kind of filtering. Wasted your money there...unless you are welding, then you need to see what the filtering percentage for UV is. You apparently didn't read the thread suggested or heed the information provided you earlier in this thread regarding what kind of filtering you need for IR and forging.... -

Back to NORM in oil and gas production, which occurs in the tubular and non-tubular goods (i. e. sucker rods). REPUTABLE scrap yards will scan any incoming goods with geiger/scintillation counters for NORM. If they detect it, it is not permitted on their property in order to prevent radioactive contamination. NON-REPUTABLE scrap yards may not give a hoot where it comes from and not do any radioactive testing. Caveat emptor.......be careful where you get your scrap oil and gas metal. There are very strict regulations in O/G producing areas as to how the scrap is tested and handled. Purple Bullet, your information on NORM should be taken to heart by anyone obtaining scrap metal, well done.

-

light form forge to bright

arkie replied to alderhardtironworks's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I had cataract surgery last year in both eyes. During the exam process, I asked my ophthalmologist who would be doing the surgery, if it was true that the IR from forging could contribute to cataracts forming...."most definitely, it's a fact that IR contributes to cataract formation." When I mentioned that I did hobby/amateur blacksmithing, he said that if it wasn't the primary cause of my cataracts, it probably accelerated the formation. As others pointed out...get some IR glasses. -

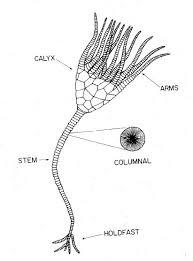

Twisted...this is what crinoids looked like (there are actually still some living species). They were anchored to the seafloor with appendages like roots. The disks you see in the rocks are "columnals", that are similar to vertebrae in humans, which broke apart when the critter died.

-

Retirement.....WAHOO!!!!!!!!!!!!!!!!!!!!!!!!!!

-

Sucker rod hardies

arkie replied to TWISTEDWILLOW's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Good application of the sucker rods. Sucker rods make very good smithing tools, such as punches and particularly tongs. Can be hard to forge by hand (drawing out reins). -

My local chain drugstore has those in the restrooms, presumably so the pharmacists can use the facilities without having to touch the door handles. Some restaurants also have those for the kitchen and waitstaff to help keep "sanitary"...seldom see them use the foot thingies.