-

Posts

161 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Razzputin

-

Thanks guys, I thought it had no credibility as the only factor that could influence it would be the earths magnetic field, but on such a small piece of steel I doubted that it would affect it in any noticible way, I just wanted clarity on the subject so thanks guys :D

-

Hey guys long time. I have an interesting question to ask but it might be a stupid one? I recently watched a video on youtube about quenching and heat treating, the question is the guy said that smiths quench with the blade facing magnetic north to reduce the possibility of warping. Is this an old wives tale or does it hold any credibility?

-

- 4 comments

-

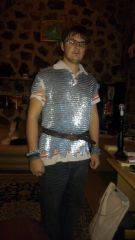

- chainmaille

- haubergeon

-

(and 1 more)

Tagged with:

-

- 4 comments

-

- chainmaille

- haubergeon

-

(and 1 more)

Tagged with:

-

- 4 comments

-

- chainmaille

- haubergeon

-

(and 1 more)

Tagged with:

-

This is my first scrolled candle holder, it took me about an hour to make because I put the cup on the wrong side twice and also made the pin to small to rivet the cup to the body. It is about 30cm across. All done without scrolling tongs, which I made later that day after realizing I actually needed them.

-

Busy weekend and goal achieved

Razzputin replied to Razzputin's topic in Tools, ID, and pictorial reference

I will do so thank you for the advice.- 2 replies

-

- hammer

- water scoop

-

(and 4 more)

Tagged with:

-

A friend of mine has shown interest in my blacksmithing work and has commissioned a staff from me. Here it is. As you can see it is not so difficult, the grooves are 2mm deep and there are a total of 20, 10 a side, the patrons name will be in the center and their initials on the ends. It will be 2m long and 2cm wide. The entire length of the staff will have a hammered texture to it and I think it will look very nice. The only problem is it might weigh quite alot but my friend says he wants to use it for training so I look forward to making this. Thank you all for reading my posts I appreciate it very much. Fell free to drop any comments I look forward to them.

-

Well on Friday I said to myself that I will finish the two pairs of tongs I started and voila! I have done it. The first pair are as ugly as sin but are surprisingly very useful. The second pair are by far much better and look great as well. Here are some pics of them as well as some of my other tools I have amassed. These are all my forge tools I have so far. From right: 1kg machinists hammer, 1 water scoop, 1 punch, 1 cutter, 1 First pair of tongs, top - Second pair of tongs, Bottom - Fire poker. Detail of the scroll work on the end of the poker. The water scoop. My first pair of tongs made from 10mm steel bar, head and neck forged, handles drawn out near head and widening to the back, this balances them very well. The two parts were riveted together by myself. Detail of the head. As you can see the one lip is longer than the other, this makes it an excelent tool to use when doing rivet work as the longer head can be placed over the rivet and is used to hold it in place while you shape the other side of the rivet.I have not included a picture but the lips have a groove down the center so as to be able to grip onto the piece being worked on. My pride and joy at this moment. The second pair of tongs I have made. The heads were forged from 16mm bar and then the neck was drawn out to only 1cm, I then cut them off of the original stock riveted them together and then welded the handles on afterwards. Size comparison. This one also has the groove in the center so as to be able to grip better. Detail of the head. Here you can also see the top lip is slightly longer, this is so that I can scoop the piece I am trying to grab rather than chase it around the fire pot. You can see the welds that I made as well. Thank you all for reading my posts I appreciate it very much. Fell free to drop any comments I look forward to them.

- 2 replies

-

- hammer

- water scoop

-

(and 4 more)

Tagged with:

-

I see the anonymous face

-

Is it just me or are the pictures not around anymore?

-

That ring of them all pounding away at the same piece and that apparently unfazed one who just held up a glowing hot piece to be pounded by those two huge hammers like it was just plastic and the hammers feathers...

-

Who is the artist you used for the song?

-

-

- chainmaille

- bag

-

(and 2 more)

Tagged with:

-

-

- chainmaille

- bag

-

(and 2 more)

Tagged with:

-

-

- chainmaille

- bag

-

(and 2 more)

Tagged with:

-

-

- chainmaille

- bag

-

(and 2 more)

Tagged with:

-

-

- chainmaille

- bag

-

(and 2 more)

Tagged with:

-

-

- chainmaille

- bag

-

(and 2 more)

Tagged with:

-

Thanks Toolish. Is there the possibility of a drawing of said contraption?

-

HHWII Thank you for that link. now I can make myself a ring cutter like that one or similar.

-

Thank you for that idea Thomas I will be sure to use it in future. Toolish the reason I use the washers is that they are cheaper than the rings I make, also they are a lot stronger as one can imagine the comparison between mild steel and spring steel. I unfortunately can not get my hands on any baling wire in large inexpensive quantities. I can only get it in 25 m lengths for about $3.60 (R32 in South Africa) a 5kg bale will cost me $60 (R500 in South Africa). The time it takes to make the rings out of the 25m bale and the fact that the steel is mild steel as opposed to spring steel as well as the fact I can get washers at $6.5 per 1000 from the hardware store ultimately means ill sway towards the pre-made rings. And as you say. the step I took in avoiding doing something a thousand times, is getting pre-wound and pre-cut rings leaving me with only the job of opening and closing them.

-

You twist them open ciladog. Toolish the rings I buy are pre-made and pre-cut 12 gauge spring washers that I get from the local hardware store. I do understand how the ring works and as I said I have tested that idea to the detriment of my finger. The ring works fine on smaller gauges of mild steel wire but not on spring steel.

-

Well I am using spring steel spring washers and at the moment I am using two huge sets of pliers to get the leverage to open them, because spring steel is as you can imagine quite strong. So I am looking for something to open lots at a time with. They aren't open enough just to slot them together otherwise I would not have asked. The opening is really the worst part of doing the chainmaille I do as it takes up a lot of unnecessary time. The ring idea i tested and as I said before about leverage and huge pliers, there just isnt enough between my finger ring and jump ring i just end up pulling my finger around without bending the jump ring at all.

-

Hi people Have any of you got a plan for a multiple ring opening jig? This is the only thing slowing down my work at present and I wanted to find out if any of you had a solution?