-

Posts

1,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SReynolds

-

I once made the mistake that I was in attendance (as a blacksmith) at a civil war reenactment. Well, wouldn't you know..............."Which Civil War"???? I be like......."For REAL" ???? But yes. I do reenact smithing in a village. Which I do semi-full-time. SO that would be part time I guess........? I do use two bellows and kneel on the floor and use only bloomery iron and wear hand- weaved cotton underwear, muslin shirt and a stone for the hammer. Tooooo funny Thomas. You are always thinking outside the box. I'd have never thought of that.

-

The use of a straight peen makes sense. Thanks. But I use the anvil corners as a fuller as well as the horn. So I doubt I'd pay 30-some for a hammer that does the fullering. But yea...that makes sense. And the cross-pein does the spreading. That is what I use the cross -pein for. But if I need to fuller a large section, I use the anvil. But seldom need to as this sin't the 1600s. If I need smaller stock I buy it. I can't visualize anyone hammering on a section of 1x1 to render it down to 1/2" or 1/4" but I know **somebody** is going to reply that is exactly what they do cuz all they can afford is free RR spikes and they have to make 1/4"- S hooks and 1/8" shank nails. So, yea. There I **can** sympathize with you and your Straight peen. I find one at the flea market for cheap I'm gonna have one cuz somebody will ask me If I have one.................someday.

-

Any Helpful Resources on how RR Track is made?

SReynolds replied to SReynolds's topic in Everything Else

I scored a section. All the rave about RR Anvils and all. I never had one. I went from reading about smithing to a factory made forge and anvil. So........ never used rail. I got this section of rail and am wondering how it's made into the shape it is and obviously what the steel chemistry is. Mine has an ultra high carbon steel wrap welded around it. Nothing I have ever seen. -

That isn't even a challenge. Throw it out and build a new one from 1/4 plate or more. With a clinker breaker too. You are off to the races!!

-

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

That is another. Blacksmith Basics for the Homesteader if I recall, mentioned the penny thrown into a fire and no welds would take. The author (DeLaRonde) likely never employed a gas shielded metal arc welder. -

anyone? What have you found out there?

-

I become quite tired of correcting the folks (tourists) who visit the shop and call me a smithy. Enough!!!

-

I have that same chisel. I cut it in half. Used the bulb on the end for the cutting end of a hardie and the handle portion is squared and forged to fit the hardie hole. The opposite end that is already a cutter was left alone. I fullered the handle and squared it to fit the hardie hole as well. Two hardie cutters.

-

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

You guys.......now I feel less accomplished. More than one popular "how to" book clearly stated you cannot weld with a dirty fire. "All traces of clinker must be removed or a new fire constructed" . One of them pointing out "it is best to accomplish all your welding at the start of the day to assure clean fire and successful welds. Apparently the clinker give off impurities preventing a weld so says another book or two. And all this time I have been welding at days end and proving these published experts wrong.......and NOW you inform me it's only by the heat of the FIRE !? I thought I was some super smith or something. I even went so far ad to scrap my leather apron and wear a cape. That is untill it caught fire a number of months back. LOL Spoilers. -

I was looking for a set (sette??) hammer and found one in the stack of used items at the local farrier supply. But the question; I have never tried a straight peen. What is the advantage of a straight? I just can;'t see paying 40.00 for one when I don't know what to use it for. Funny in that a cross pein is less than half the cost of a straight. Why? If I can locate one for the cost of a cross pein, I'd have one. I can see where the coveted 45° pein would be nice.......but never seen one for sale. Maybe eBay?

-

TSC coal sale

SReynolds replied to BAndritsch's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Probably the rice sized. It would go down into the bottom of the fire pot and plug off the air.He was using some of the nut sized with the soft coal I sold him. The Hard coal-nut sized was recommended by a friend of his who performs some smithing on the other side of the state. But I can tell you I have tried some nut sized hard coal and I was embarrassed to have to perform in front of a live studio audience. It just wasn't right. In fact the guy I replaced said not to use it. It was dumped on top of the soft coal and can remember digging for it. But he was on the way out and I took over. Now it was my problem and had a time to get rid of it. Even visited TWO stove shops that sell it and THEY didn't even want it. I hauled it around and was about to dump it in the land-fill. I found an Amish shop that wanted to use it in their coal furnace. It was quite a truck load. Now that I have all soft coal, it's like sliding into a hot tub. Very relaxing and you have no worries. -

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

1/8" flat is what I started with. It welds easily. Thus I employ this inthe welding class I teach. They do it when they never have forge welded prior to this. So it must be a good idea as they learn how to forge weld for first time. Then I have them move onto lap welds with two individual lengths of 1/8" thick flat stock. That too is an easy weld. But my point is the source of information . An individual must get it somewhere. What would be a reputable source? If not books then youtube? Or this site? That alone is a challenge for a beginner. I worked under a talented smith (per the work he does) but insists that water quench cools slowest and heavy oil the quickest. I have met a smith who informed me you harden low carbon steel at black heat and quench in engine oil. So yeah. I'm trying to point out there is alot of bad information. -

TSC coal sale

SReynolds replied to BAndritsch's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

That is true. He had purchased both. I can't say for sure. it pops and crackles like shale. It would plug the air holes. I remember clearing the air holes and cranking the champion blower and nothing was happening. The steel was trying to turn red. Wouldn't go to orange/yellow. -

TSC coal sale

SReynolds replied to BAndritsch's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I had a student of mine take over operations of a shop in a historic village. I sold him several bags of soft coal. Visited him sime time ago and was doing well with soft coal and the old Champion 400 Whirlwind Blast fire pot. I returned recently and he had purchased the TSC hard coal. It wont work in the fire pot. Fight. Fight. Fight.Troubles. Troubles. Troubles. I raked it out. Threw in some soft coal I sold him and he was heating steel. -

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

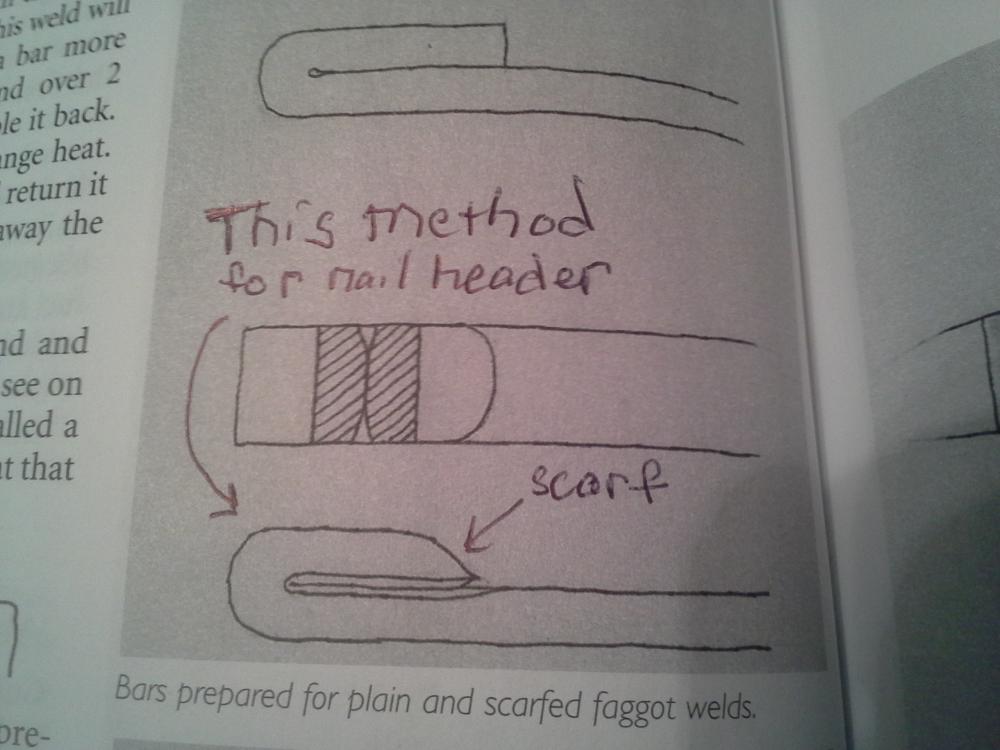

I don't know. I don't write books. This is his second book so he must know how to do it. He clearly states if you don't scarf a foggot weld, the weld is weak. I do however recommend performing this weld as a beginner .........with thin flat stock. 1/8". I dont scarf it. As is too thin. I will experiment cutting part way through and then folding it with my (thicker) horse shoe stock. -

My table top forge with firepot has a cut--out at far side. I use a gate to forge smaller items and remove The gate for longer sections . To keep coke off floor I have a tray under gate about 5" by 12" long. I dont push out more than I have to but what falls out is held by the tray. Likewise I use a similar set up for front of forge. Also serves as a tool/workpiece rest. Keeps me from stepping on coke.

-

Two common methods I employ include notching with a hack-saw when I can ..... or liquid paper corrective fluid pen. Unless you go into welding heat, it won't burn away.

-

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

That is the point I brought up. The Andrews books says otherwise. You must scarf the joint otherwise cold shuts are formed. I have performed the task each way and both can form cold shuts. -

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

I dont know if he makes swards. Probably just writes books. But his isn't the only book that will Inform you, you have to scarf. If you don't, it is reported the two sections are apt to slide. And cold shuts. I don't write books. I just read them and experiment on my own. Everyone would seem to have their own opinion. -

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

In this book it is clearly stated that you can attempt the faggot weld w/o scarfing but it will result in cold shut. I see you tube videos of large knife makers ( no, not a hobbyists with drum forge outside and rr spikes) who layer iron and steel and weld with hyd press. They don't seem to scarf. Thus jack Andrews book new edge of anvil will point out they build swards incorrectly as their welds are bad. -

So would Fold Forge Welding be fine for a start?

SReynolds replied to jacbow2's topic in Blacksmithing, General Discussion

That is known as faggot welds. Not fold forge welding. no such thing. -

Yes. Right here in northern ohio is a company building steam locomotives. Ageofsteamroundhouse sugarcreek ohio

-

Let the HAMMER do the work (?)

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

You know.......if that is true and I don't particularly have reason to believe it isn't, I have thought about the anvil and why it's so important to locate the 80% rebound anvil as opposed to , I don't know........much less I guess. I subscribed to the wear resistant surface of high carbon compared to a softer surface. And moving the mass (velocity) is one I will try to remember. wish I could have said something more intelligent than simply "YOU GOTS TO SWING THE HAMMER" !!! -

There are three large scrap yards in Mansfield ohio very near and they don't allow it to set about. It is sorted and ground into steel mulch. Same as aluminum. I cant imagine digging through that to pick out what may or may not be wrought. I don't believe you can even go in unless you have a load to drop off. You can tour the auto scrap. Spring steel etc. But even if you locate wrought somewhere and it is in plate form ,I cant imagine the process to render that into usable stock.