-

Posts

181 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by lloe01

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

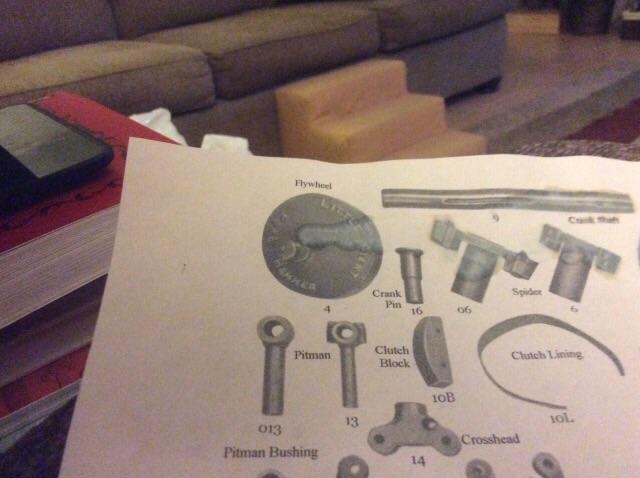

The ram guides are brazed, but they don't look adjustable anyways, even at the top. As for flywheel, that is what it says on Little giant resources Parts diagram. Remember, this is a Mayer and not a Little Giant. Parts may be different. But, then again, whoever owned this hammer loved brazing.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

The big ring that was wrapped around the flywheel is blocking me from removing the ram or it would be on my work bench. I thought about grinding it. I figure it is not worth it and didn't want to weaken the ram ears. There sure are a lot of ears on this hammer! I still might be able to get that ram off when I can dedicate some more time to it.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Ordered my bushings again. Should be here Saturday. Meanwhile I tried to cutout the pins that are welded into the ram, connecting the toggle links to the ram. I tried a hacksaw, nothing. The blade did even bite So, I tried my sawzall and got the same result.....nothing. Finally, I got out my portable bandsaw and it wouldn't even bite the metal. Maybe I can get my torch and heat it and then try the bandsaw again. This hammer is fighting all the way!- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

The bushings came in today. Dang, they sent the wrong size, way too small. Trying to contact the company and let them know.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Thanks Frosty. I do, sometimes, work barefooted. Not with hot stuff, tho! Just putting things together in the garage it would definitely hurt if I dropped an ear on my toes.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Ok, I didn't have to take hardly any thing of the ear of the arm. Actually, all I did was remove the paint and smooth the ear so it wasn't rough. I then took a few thousandths off the inside of the ears of the crosshead and it fit great. Now I am waiting for the bronze bushings to insert into the ears of the arms. I also need to get the 1/2" pins for the ears of the arms.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Pitman shaft measurement

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Frosty, I got an answer from Roger. He said the pitman he had was 1-1/8" so it is about 1/8 inch wider then the one I have for the Mayer. Thanks! -

What is the diameter of the shaft of the pitman on an LG 25 lber? Thanks

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Frosty, I am looking for another crosshead. I'm have emailed Roger to see if he might have anything I can use. If I had actual measurements I could get someone local to fabricate one. thanks :)- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Sorry, Frosty, just a casual welder. on one side of the crosshead, the ears of the crosshead, where the arm fits between them and you then put in a pin or a bolt, they are not wide enough for the arm to fit. On the other side, the arm fits and I still have about a tenth of an inch clearance. Augus7us, i emailed Roger with the pitman measurement, hoping he had some kind of crosshead that might fit it.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Jeremy, I would love to fabricate a new crosshead, but I'm not a machinist. I don't have the measurements to give to anyone, either. It is a good idea, though. Thanks I measured the pitman at the bottom. It is .98" diameter. Anyone know if that is the correct measurement for the Mayer 25lb? Of course, if anyone has a spare crosshead for a Mayer/Moloch 25lb, I am interested.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

On one side, there is enough room. It is only on one side where the ear isn't wide enough.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Ok, the ears of the arms are 3/4" thick. The ears on the crosshead are only .71" apart. I cannot grind the crosshead ears as they don't have a whole bunch of metal of them. Being the crosshead ears have been brazed, that bothers me too, if I was to heat them up to bend them out a little.So, is it ok to remove some metal from the ears of the arms?- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Frosty, you are a genius! Bushings! Brilliant! Looks like they need to be 3/4" OD, 1/2" ID and .4" long.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

The parts came in today, yay! But, while the new parts are awesome, they don't seem to fit. In fact, I can't drill them out to fit the crosshead because there wouldn't be much left to the upper ears of the arms! sheesh! Help?!?! Any ideas, anyone? I'm thinking about drilling out the original crosshead pins to the size of the new ears of the upper arms and using them as sleeves for pins that do fit the new arms.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

I just cleaned up the pitman and cross head. They had so much grease that I didn't discover they had both been broken and brazed at some time in their use life. Anyone have a spare Mayers/Moloch cross head and/or pitman? Notice the wearing of the bolt head on the cross Head? I will have to check the Flywheel to see where it was rubbing. Larry- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

I wanted to get a new pitman and cross head, but Roger said he didn't have anything that would fit it. That would have made it even more expensive. Of course, I paid $800 for it knowing I would have to do some repair. Once it is running again, it still will be pretty cheap, I hope Kozzy, I will keep it in mind in case it doesn't pull as well as I think it should. Thanks!- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Mouse hole? can you show a pic of the other side? incredible shape!

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Just talked to Roger. i ordered: 2 - H12 Toggle Arm for Old Style 1 - H15 Spring 2 - H18 Lower Toggle Pin: Standard .625 Diameter 2 - Tension Adjusting Knuckle They are in the mail and I should get them in a few days. Once I get those, Roger said we will need to make measurements and then customize any other parts I need. He did say to place a 1-inch block between the dies to take proper measurements. I have some metal cutting to do to get the old Toggle links removed from the ram. The old links were placed on the pin and then the pin was welded to the ram. This should be fun- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Serial Numbers 34001-42000 were made in 1903. Postman says the "A" stands for "Anvil".

-

Is that a big diamond on the side? It might be a Trenton. I have a 450 lb Trenton. Here is the diamond on its side:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

I called Roger at LittleGiant and he wanted me to send him my shipping info and some pics of the hammer. I hope he has the parts I need He said he would get back to me tomorrow. Woohoo!- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

I did run it for a couple minutes after I got it. It ran well, but I was concerned with the parts and felt it would be safer to repair it before I started using it.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

it does look different from the LGs. I thought the same thing.- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with:

-

Working on my Mayer 25lb

lloe01 replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Thomas, I'd never heard of that. It shocked me when I finally realized there wasn't a spring. At first I thought the spring had shattered in the tube. But, nope, rubber tube :)- 81 replies

-

- moloch

- little giant

-

(and 1 more)

Tagged with: