-

Posts

68 -

Joined

-

Last visited

-

I know methods of grain refining by normalizing carbon steel by heat treatment, but these methods would take hours and hours in stainless, so I don't think this is an option. My metallurgy is not completely up to date, but I did investigate this: https://japaneseknifereviews.files.wordpress.com/2017/07/reducing-grain-size-in-pattern-welded-damascus-steel.pdf If anybody knows a method to do this in stainless, I'm all ears

-

Oh, I forgot to mention why I like the screwpress, the flywheel accumulates a lot of energy, so with a relatively small (7,5kW) motor, you can have lots of forging impact. The beche powerhammer also does this to some extent but has a 18,5kW motor. I got 3x25A electrical mains so the 40A motor is a bit on the larger side. Further more, the screwpress won't need a big and heavy fundament. I think I should also mention I only need the machine (powerhammer of screwpress) for drawing out stainless billets. Most other operations can be done by the small hydraulic press.

-

Hi everybody, I hope you can help me with this question. I have already made some stainless damascus on my little 20 ton hydraulic press (33mm/s ramspeed), I succeeded but I had to make the stainless so hot that I got too much grain growth so this is not the way to go. At normal colder temperatures (1100 degrees Celsius max) the press won´t forge the steel. Years ago I bought his 150kg Beche LV4 powerhammer. I never installed it because I was in a rented building. I am 100% sure this hammer is strong enough to forge the stainless, you can see Devin Thomas using the exact same hammer. Recently I bought a new workshop so I might install it, but I am not 100% percent sure I will stay here so I don't really like the idea of putting 6000 euro's worth of concrete etc in the ground. The alternative is a 100-200mm thick steel plate on special air inflated machine dampers but the steel plate with current steel prices will be +/- 15000 euro and the dampers +/- 4000. I can do a lot of other things with that money.. So I was looking at this 100 ton Berrenberg – RSPW 125/100 screwpress, I attached a photo. Do you think press will be strong enough to forge 120*40*120mm stainless blocks? I know Marco Guldimann used a similar but smaller press for his carbon damascus, you can see him working with it in the video. Thanks for you input! Kind regards, Johan van Zanten www.vanzantenmessen.nl/galerie/

-

very creative, congrats for building this!

-

[Video] Gas forge exhaust gas extraction system

Lateralus replied to Lateralus's topic in Chimneys, Hoods, and Stacks

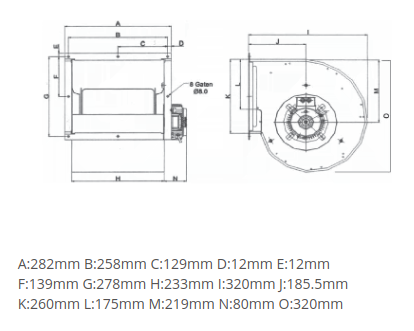

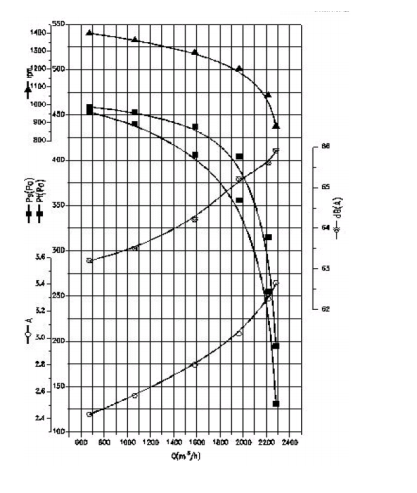

Latticino Thanks for your technical response. First I will add some fan specs: • Flow: 2650m3/h • Weight: 21kg • Power: 1080 • 4 pole • 1400 rpm • Ø 250mm • Voltage: 230v/50hz • Dimensions: 450x450x450mm https://www.spirototaal.nl/stalen-ventilatorbox-2650m3-th.html Does larger ducting make less noise? First I made my design with 13" ducting, but that would have resulted in an even larger fan box (for correct intake size) so I choose 10". The system is very quite now, with earplugs in I can't hear it, this is kind of scary because I won't know if it is working, but I do take a look at my CO2 meter often and I have a CO alarm nearby. Yeah, have a look at the video Thanks. Fun fact about the forge, it has ribbon burners, but they are not cast in refractory, just drilled holes in insulating fire brick Working great for over a year now! Much easier to make. The forge has a PID which works as a thermocouple readout, it is not controlled by it. I'm tuning the gas/air mix while working with it. For instance, when I want less scale or when I take a kerosine weld on a piece of damascus I crank the propane up a lot. When the bricks are hot it idles real nice at 1250 degrees Celsius at the lowest setting. Here is more about it: https://www.youtube.com/watch?v=eNDa3fWvALY no I don't, the exhaust of the forge is in the back so the bulk goes backwards, the door is closed 95% of the time -

Gas forge ventilation via sheet metal hood

Lateralus replied to Adodero's topic in Chimneys, Hoods, and Stacks

this might help you? let me know when you have questions -

Hello everybody, I couldn't find any info online about making a proper gas forge exhaust gas extraction system, so I decided to build one and make a little video about it. There are very nice smoke extract fans for sale online (ruck.eu), but I decided to buy a cheaper regular steel box fan and retrofit it with a little trick a learned from "Smederij de Waard - Wanroij" in order to keep the motor and bearings cool. The system had to be as quite as possible, the gas forge itself is very quiet, so I don't want the sound level to be overruled by the fan. Two big sound dampers are used, also to suppress the noise as much as possible for the surrounding neighbors. Specs: Ducting: 250mm Box fan capacity: 2600 m³/h (maybe 2000 m³/h after the retrofit) So far it is working really well, the motor stays cool. Next thing would be proper electrical wiring and a on/off switch..

-

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

Thanks guys! Thanks > kachelmaterialenshop in Nijkerk for most of the bricks etc, steel at MCB, electronics at TechnischeUnie, stainless steel at RVSPaleis, valves etc at Tameson, air pressure sensor at Huba Control. The blower can be bought new for 146 euro incl VAT at Warmteservice, it is a 24 VDC Intergas Torin. It's a regular household heating gas combustion fan. Pretty silent, I run it at 13,8 V, more than enough flow and pressure. -

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

Yes it is! Greatest band ever in my opinion So far I did my first canister weld, not flux free without other protection so far. It frightens me a bit. When the oven runs at welding temp and I add some extra gas for the dragons breath, I don't really know how much extra is needed. I should just try it, but to be honest, I don't really believe it will work, I do hope so though. Maybe first a WD40/kerosine weld to get some more confidence? I attached the knife with the latest pattern. With the new forge it was real nice to have long even heat for twisting the big bars. I do have some problems with clogging holes. I don't understand how they become clogged, I had to push a little rod through a few holes. Another problem I had was with the steel square tubes in (front of the burners bricks) heating up too much when first using the forge at full temp for hours, and than ramping down to the smallest flame, in that case, too much heat is getting back and it gets cooled too little by the gas/air mixture, so I had a backfire or something, at least some loud explosions. The forge didn't bother luckily. I might solve it by placing a Peltier module on the steel square tubes. Other than that it's working great. https://www.vanzantenknives.com/ here is some more info on the Merovingian twist. -

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

-

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

Frosty, thanks for the explanation. Your forge looks very usable for putting in different shapes and sizes of stock and workpieces. At this point I'm not so sure what to do with the inner lining. I have the following concerns: 1. What will re-radiate heat better, an IFB surface, a INTOVAL T 85 SP 10 REPA surface or a Plistex surface? So this has to do with the thermal conductivity and the specific heat capacity of the material. I suppose the IFB will be the worst. 2. Will the IFB surface hold up to abuse from putting stuff in the forge and damaging the walls, specifically the burner holes which are vulnerable. Will a refractory wall be better, and can I make a wall with burner holes in it, without getting shrinkage and rupture problems? Mikey98118, The brick is in the attachments PDF. I have the TAI-28. Do they match the brick you are talking about? I also uploaded a little movie about the current status of the forge. Wiring is done, actually pretty much everything is done, I only have to make the hood. It is running beautifully even, I'll make a better video soon when everything is done. VID_20210203_151837.mp4 Data Sheet Insulating Fire Brick.pdf -

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

hahaha yes it does look so! Frosty yes, the air mistake was a real no no. Today I got my pressure sensor, Monday I'll make the safety system. OK, so you suggest leaving the air on after shutdown, I was thinking about that, I was afraid the cool air might make the burner block crack earlier, but your argument is also valid, hmmms, I'd have to think about what's best. I still don't really understand the difference between a kiln wash and a refractory cement. I do have INTOVAL T 85 SP 10 REPA (as in the attachment) laying here (refractory), but I guess a kiln wash is from different composition and maybe thinner and easier to apply with a brush in thin layers? Do you mean you built a certain forge depending on the materials you got on hand? What is your latest and most usable forge? Would be great to see some pictures. I have to say, I don't do regular smith work, only bladesmithing and maybe heat treating. INTOVAL T 85 SP 10 REPA INTOVAL T 85 SP 10 REPA(1).pdf -

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

I fixed the burners, and decided to mason the bricks together. Did a little painting job and bought another blower. The bigger one uses 200 watt 3 phase, the new blower is from a boiler, 24v DC 2A, 48 watt and still has more than enough power. It is quieter too. By the way, these ribbon burners are very silent! I'm very happy with that, keeping in mind the loud roar from the venturi burners I'm used to. Today I checked the lowest possible air setting for the gate valve (photo), I'll make a little stopper in the valve so I won't have backfires anymore. The next thing is wiring. -

Lateralus changed their profile photo

-

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

Commercial link removed per TOS. Here it is, Seal-It 211 Silicon HT, it goes to 300 degrees Celsius. It makes a very good glue bond between the brick and the steel. I had the oven running for 45 minutes, and during the run the silicone kit never got hot because of the cooling effect of the gas/air stream. When I shut it off, it did get warm, but not above 75 degrees C. So I guess it will be fine after hours of running, but that will still need to be proved. -

Dual IFB ribbon burner gas forge with retractable rear wall

Lateralus replied to Lateralus's topic in Gas Forges

2600F, for the bottom, because there was not enough 2800F left in the store, the rest is 2800F and the burners are 3000F insulating fire brick. Unfortunately they break very easily. Maybe they are low quality...? I'm thinking of getting the walls together with mortar for extra strength. This is what the backfire explosion did with the burner: