-

Posts

119 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Will-I-am

-

Portable cordless bandsaw recommendations

Will-I-am replied to BillyBones's topic in Saws, bandsaws, hack saws, etc

-

Mr. Powers, I do not think I can get the temp hot enough to hot cut yet. I would love to hot cut, but still working on temperature refinements. I would have to cut on edge of anvil since I do not have a hardy hole cutter or good chisels yet. Holding the hot metal steady while using chisel is more advanced for my current level. No vice either just vice grips and first tongs that only hold larger round stock comfortably. I am still learning to draw out metal. I like the way the ball peen hammer works on the anvil edge, very fulfilling. I will continue to draw out the machete handle until it is round and I can hold it comfortably. Then I will heat the blade side and start drawing out the blade on both sides and then final sharpen with angle grinder. I want to shape the whole blade by heating, just for the experience. Originally, I tried to cut the stock closer to a bowie knife size but the leaf spring was way harder than any steel I have ever tried to cut with jigsaw or reciprocal saw. These saws literally bounced off the metal, so I used angle grinder which was very difficult even with cooling oil. Almost burned up grinder and used 1/2 disk for 3 cuts through spring steel, one point and one heel. I want to hammer the blade angle instead of grinding it to shape. Hot cutting intimidates me for now. Holding a luminous piece of metal and hammering is enough for me right now. Safety is important; some of that hot hammered scale flew off and landed on my feet and legs but luckily I was barefoot and instantly moved, similar to hammering without gloves.

-

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

Since the carborizing process (adding carbon to reduced oxygen iron in bloomery) is only on the surface of billet, would this account for differences in rust? The final forge welded helix would be twists of high carbon and low carbon and rust at different rates? -

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Mr. Powers. I looked up the term pattern welding. https://en.wikipedia.org/wiki/Pattern_welding. Very interesting. It talks about the Vikings twisting long bars together forge welding and then repeating. This helix pattern is the Wurm you are referring to? -

Brick side draft chimney plans?

Will-I-am replied to will52100's topic in Chimneys, Hoods, and Stacks

This Sauder guy has an interesting plan for incorporating regular .50cent bricks with a fireclay ($9 for 50 lb bag special ordered at building supply) mortar. Then stacking mixed fireclay balls around a wood form to form chimney that will withstand 3000degree heat. Regular mortar cracks under high heat but fireclay melts to ceramic. This plan idea could be incorporated into a coal chimney design. https://s3.amazonaws.com/images.icompendium.com/sites/eliz2406/sup/3696366-furnace-construction.pdf -

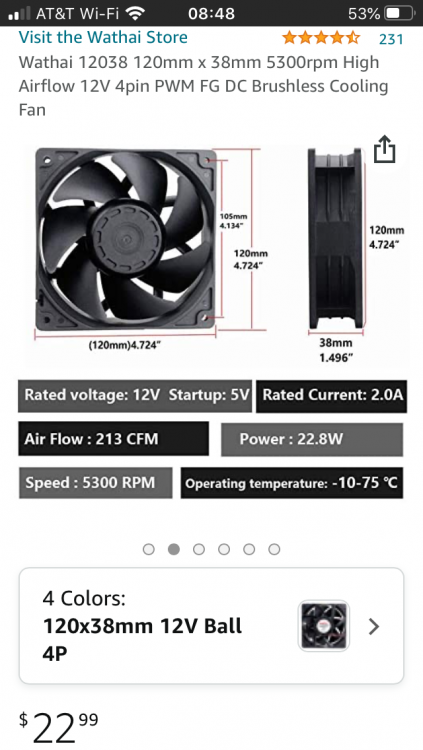

Substituted new 9” diameter centrifugal tuyere fan for old 4” fan. Twice cfm, 4xwatts and way more push and only 50 decibels quiet. On high the fan cools material but on low it is perfect but gobbles up wood. Cut 30lb spring steel found on hike; still sore from hauling on back 4 miles. New jigsaw blades didn’t dent steel and reciprocal saw was similar, so had to angle grind. Used grinding oil but was a chore. Originally wanted to make Bowie but would need more disks so now a machete. Spent all day trying to draw out handle using ball peen and edge of anvil. Fan made fire a little hotter, hot enough to see first black chunks of scale over yellow. Hands sore. A good day.

-

Concerning my above pic of spark test. Looking at spark chart images my greenhorn opinion would be mild but shouldn’t the spark be white and not straw color? Since leaf spring was found off old logging/ mining road 4 miles deep from both directions, up 1500 ft in dry cold desert climate, near copper mines. Mining truck leaf spring over 50 years old? Ore trucked down steep rocky dusty bumpy roads. Then ore put on trains in flat. More info to help with identification.

-

Me and the wife went on 8 mile hike over the mountain today. Checking out old copper mine, found 30 lb 5ft tall leaf spring. Hauled back on sore shoulders for 4 miles! Did spark test. Medium carbon steel, good for first knives?

-

Frazer, this is different from a regular booster fan. The old 100cfm fan which was regular 4" "almost" worked even after 2x 90degree bends and 10' 1" pipe, I got the material always bright orange and sometimes yellow. It was 15 watts the new one is around 60 watts. Yes, there was back pressure and yes there was ash buildup. This new fan is different, the larger centrifugal 9" flywheel combined with twice the cfm should overcome backpressure and certainly be a large gain from the old fan. I expect more yellow. Also the fan blades are spinning so that there is little friction which will also lead to less backpressure, see pic. Plus very quiet.

-

I ordered this vivosun 4" fan and it will arrive in the mail tomorrow. It is variable speed so dialing it in for multiple forge types should work. I was using a hvac booster fan with only 100cfm and it would not get the material color past bright orange. This new fan is twice the cfm and also is a larger 9" centrifugal like the hand cranks which has more push and less backpressure when ash, clinker and whatever tries to clog/block the tuyere. I cost $50. excited!

-

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

Lee Sauder's area on his site called "smelting research" has quite a number of research papers that are a highly educational read. Just finished reading 5 papers he wrote on bloomery and he even has one just on bloomery construction plans with lots of pictures in each paper. His concepts and his "clay mix" could be incorporated into normal forge builds. Gets the creative juices flowing. -

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

just typing in Lee Sauder in the search bar on this blog get 72 hits, way more if I use a search engine. Why would a link to his website be removed, I could not find a reason in the rules? His research papers are a foundational read. -

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

I was digging through this blog looking for more information on bloomery and someone recommended checking out this guy. Wow! link removed His research papers are especially interesting. Forging totally from scratch from ore to axe. Converting iron oxide to iron and adding carbon to iron in a fire. There are a lot of copper and gold mines here in northern washington. Ideas are flowing. -

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

It would be really satisfying to create a knife from a primitive bloomery. I found this fun link with lots of pictures of a modern viking age bloomery reproduction. http://www.hurstwic.org/history/articles/manufacturing/text/bog_iron.htm -

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

Mr. Powers, what an amazing experience it must had been to participate at Pennsic all those years. Did your Scandinavian team build the bloomery from scratch each year? I am curious about the short stack build, any pics? Even better is if you have a link to the ironmaster research paper, would love to read it? -

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

I was under the impression ancestral Iron was made my smashing iron rich ore rocks and heating in bloomery. As charcoal is added and higher heats are obtained more ore is added and charcoal carbon is chemically mixed with iron to make primitive steel, then billet then sword. wikipedia: A bloomery consists of a pit or chimney with heat-resistant walls made of earth, clay, or stone. Near the bottom, one or more pipes (made of clay or metal) enter through the side walls. These pipes, called tuyeres', allow air to enter the furnace, either by natural draught or forced with bellows or a trompe. An opening at the bottom of the bloomery may be used to remove the bloom, or the bloomery can be tipped over and the bloom removed from the top. The first step taken before the bloomery can be used is the preparation of the charcoal and the iron ore. Charcoal is nearly pure carbon which both produces the high temperature needed for the smelting process and provides the carbon required for the steel alloy. The ore is broken into small pieces and usually roasted in a fire to remove any moisture in the ore. Any large impurities in the ore can be crushed and removed. Since slag from previous blooms may have a high iron content, it can also be broken up and recycled into the bloomery with the new ore. In operation, the bloomery is preheated by burning charcoal, and once hot, iron ore and additional charcoal are introduced through the top, in a roughly one-to-one ratio. Inside the furnace, carbon monoxide from the incomplete combustion of the charcoal reduces the iron oxides in the ore to metallic iron, without melting the ore; this allows the bloomery to operate at lower temperatures than the melting temperature of the ore. As the desired product of a bloomery is iron which is easily forgeable, it requires a low carbon content. The temperature and ratio of charcoal to iron ore must be carefully controlled to keep the iron from absorbing too much carbon and thus becoming unforgeable. Cast iron occurs when the iron absorbs 2% to 4% carbon. Because the bloomery is self-fluxing the addition of limestone is not required to form a slag. The small particles of iron produced in this way fall to the bottom of the furnace, where they combine with molten slag, often consisting of fayalite, a compound of silicon, oxygen and iron mixed with other impurities from the ore. The mixed iron and slag cool to form a spongy mass referred to as the bloom. Because the bloom is highly porous, and its open spaces are full of slag, the bloom must later be reheated and beaten with a hammer to drive the molten slag out of it. Iron treated this way is said to be wrought (worked), and the resulting iron, with reduced amounts of slag, is called wrought iron or bar iron. It is also possible to produce blooms coated in steel by manipulating the charge of and air flow to the bloomery. As the era of modern commercial steelmaking began, the word bloom was extended to another sense referring to an intermediate-stage piece of steel, of a size comparable to many traditional iron blooms, that was ready to be further worked into billet. -

I have been thinking of upgrading my tuyere fan with more cfm. The hvac fan I am using now is only 100cfm. It is quiet and works to get the work bright orange with rare hues of yellow. I cant forge weld, and the hammering is more labor intensive with typical orange color. I am leaning toward a centrifugal design with larger diameter like the hand cranks but electric with variable speed. The extra 100cfm should help with back pressure as the ash builds up and get me to yellow and maybe the rare white. This one is 200cfm with 10" diameter centrifugal and around $50 bucks with good ratings for continual use and quiet. VIVOSUN 4 Inch 203 CFM Inline Duct Ventilation Fan with Variable Speed Controller

-

Paul, a bmx guy used to frequent one of our skate spots in 80’s. He did beautiful G turns on his front wheel; I could do G turns on my skate and it was very satisfying. Did get into mountain biking, loved to launch off bumps. Pnut, I never had bowls just street and street ramps growing up. You are inspiring me to pull out that old board. Remember zorlac boards, skate tough or go home. Happy just trail running now.

-

Show me your blacksmith pets

Will-I-am replied to Glenn's topic in Blacksmithing, General Discussion

This is our 10yr old Shadow. Lab/Belgian Shepard mix. He stays outside and guards animals. He goes on every trail run with me and the wife. He likes fire pit but hates anvil. -

Pnut that’s interesting you are still skating. My prime was 89. I skated some of these concrete skateparks with my kids, but local youth had that who is the old bald guy look. I could still olley ok but not knee high. Knee surgery 6 years ago after bike accident ended skating. Started running for recovery 5 years ago. Just turned 50 years old and I trail run with my wife 10 miles a week; best thing I have ever done.

-

Frazer you are probably right. I didn’t realize Dave had a battery and thought he was trying to run dc direct from solar panel to fan. With a large enough panel 200 watts this could work. The fan I suggested looks like computer fan and probably would only produce 75cfm. The centrifugal fan Dave suggested looks nice; since same type as hand cranks. Is 100 true cfm the target cfm?

-

Nice class of 89. I also skated hardcore. Kick flips off loading docks, built huge number of street ramps, rail slid handrails; that’s how I learned skills to build house and cabin. Good memories. Then came snowboarding mt baker wa.

-

No debt, what kind of motorcycle do you ride? I love my husqvarna 701 enduro with an aftermarket pipe, cool backfire.

-

That sea flow centrifugal is sweet; and add variable speed controller to dial it in.

-

I think Dave is looking for dc fans not ac. This one could be run direct from solar panel with no battery and is boasting high cfm, probably exaggerated.