-

Posts

119 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Will-I-am

-

Also, using the right tool that is most efficient and safe for the given task. For instance an angle grinder will cut a 55gallon drum but a reciprocal saw will do it much safer.

-

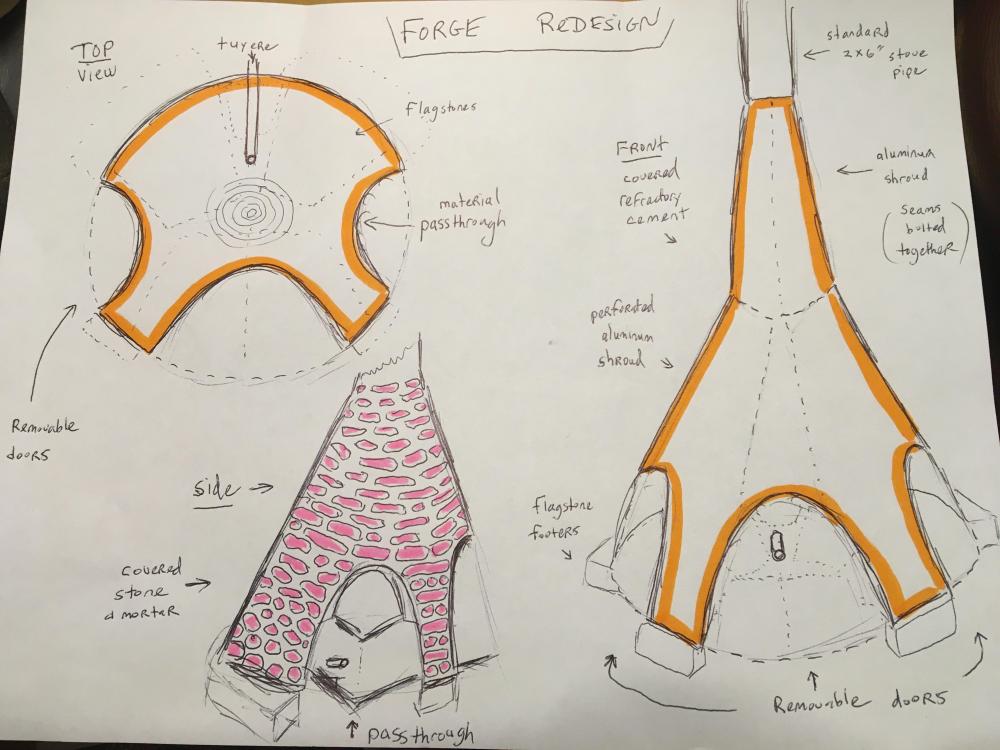

Fire pit rebuild plan. Previously, i can only heat 6” of material end to forging temperatures; so need a pass through ground forge. Will use perforated aluminum as form for hood. Cover holes with refractory cement then rock. Removable doors.

-

That Gurdy guy jams. He is the joe satriani of that instrument. I played guitar since a teenager and appreciate his skill.

-

Too late now, pins have been in for 10 years. Fortunately, there is a desert climate here in eastern washington, so not a lot of rust, but lots of wind and dust. My wife thinks everything I build is an "eyesore" aka scroungehenge. When Jim Morrison faked his death and changed this name to Rush Limbaugh, he said scroungehenges are a natural form of art. Long live "riders on the storm".

-

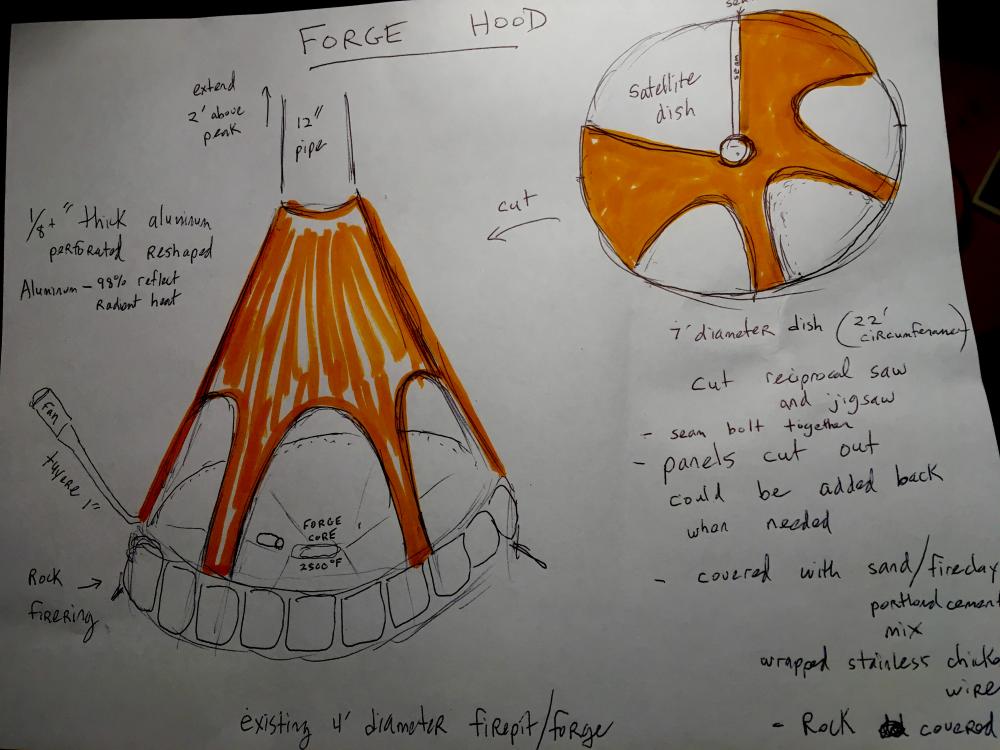

Call it lodgepolehenge. Not all the firepit smoke exits the center cone hole. So I decided to cover the firepit with a hood for the sake of healthy lungs. I took a 9' diameter 1/4" perforated aluminum satellite dish and cut it in half. Annealed it and bent it in cone shape with body weight. Plan is to take other dish half and roll into 15" diameter to 12" diameter pipe and connect to standard 12"(2x6") stove pipe. All perforated pores will be smeared with refractory cement and then covered with rock. Yesterday I decided to rebuild the whole firepit so I have a passthrough to forge longer objects. I have more large flagstones to use as a footing for the hood since it will support considerable weight covered in rock. Will also have removable access doors so the hood can be used as firepit for entertaining (drumming) or forging. Have been chainsaw carving a djembe drum from 21" sycamore cut from property, nearly finished, in pic. Have to sweep the shop after every forging session because of the woodchips generated from rechargable chainsaw could be fire hazard. Spent all day trying to draw out the reigns on tongs, seen in pic. Progress is slow but building dexterity with ball peen. I need a lot of fine tuning to get more yellow/white colors instead of bright orange.

-

I built a shop 10 years ago on lower bench of my property. This "agricultural building" was an experiment in primitive construction. Drilled 12 holes equal distant on 20' diameter circle and inserted treated poles. Leveled pole tops and connected with lodgepole pine half notching and drilling with rebar pinning, like stonehenge. Cut 14' lodgepole from forest loading each piece on my back to truck. Created reciprocal roof connecting to rebar pin, which left cone with open circle in center. Rock firepit added under center smoke hole. Over the years added some cement walls and cedar walls and metal roof. Recently converted firepit to forge by adding tuyere 1" pipe with electric variable speed hvac booster fan. Lined firepit with large flagstones.

-

I have decided to start an area dedicated to all my projects. The new 136lb anvil was originally quite loud in my shop, so I deadened it down with a tow chain. I have an old busted guitar amp that I could scavenge a magnet from to deaden further. The chinese steel held up well for first two hammering sessions. Angle grinded leaded edges and spark test revealed high carbon steel pattern. Swung hammers my whole life and never used ball peen until recently. Ambidextrous hammering helps me balance bodily stresses and hammer fatigue.

-

Just ordered some refractory cement to trowel over the aluminum mesh. This stuff should work until I can cover with rock. Just need to use cinch straps to tighten up the top and add extra mesh to fill in transition to 12" pipe and bolt together by march 1st when cement arrives in mail. Dries in one day.

-

On the east porch, I built a chiminea. Took 55 gal drum, sawed top to cone wrapped in chain link fence. Cut arch door added pipe and covered in mud. The mix was 1/3 fire clay, 1/3 sand (filtered subsoil), and 1/3 Portland cement. Still used today but has some cracks.

-

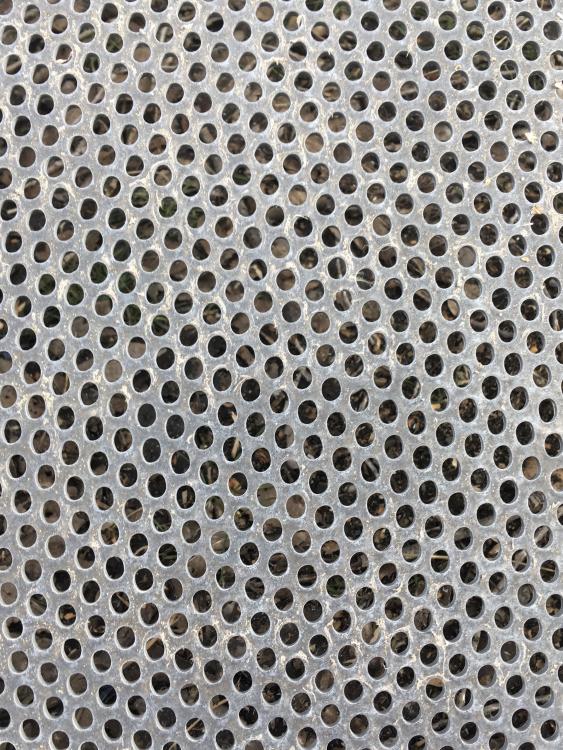

Worked all day in shop. Reciprocal saw cut aluminum easily, then split dish in equal sections then cut off curled ring off bottom shroud. Bent by stepping on inside and pushing, didn’t need come along. Anealed over fire pit then moved outside and bent again by body weight. Micro fit around fire pit and bent edges. Added cutoff curl too. Made fire much hotter. Forged without gloves but still got too hot a few times. Worked ambidextrous both sides of anvil, moving material constantly. Ball pien hammer is fun. Made point on poker, worked tongs, shattered aluminum motorcycle bonz, chainsaw carved djembe drum and drummed a little too. Hands sore a good day. Aluminum fumes?

-

-

Goat lady, is that fine critter you have a Nubian/boer mix? My buck has to go, smells XXXX XXXX, gotten stronger in last week.

-

Great idea; I do have a come along. Will try winching tomorrow; that is not a winch joke. Thanks for supporting my idea.

-

Not sure on type of aluminum alloy. When I used angle grinder to weaken welds to remove aluminum cap, had to be careful not to cut through mesh. Seems soft when heated with angle grinder. Mesh is strong but flexes with 20lb pressure. Will use reciprocal saw and try to bend by hand /with torch heating. Here’s a good laugh, wife said I am taking this tin foil hat thing a little too serious, pic.

-

Goat lady, we started with ducks 15 years ago and enjoyed many years of eggs but eagles, coons and poor laying location ended that. Then got pregnant sow and raised pigs. Then did free range chickens. Decided 5 years ago to coop them up because our front porch was becoming messy and coons were bad. Killed lots of 30lb coons. We have mixed breeds of all colors. They are getting old now. We used to get 15 eggs every day now only 6. Start fresh in spring. One old rooster and 20 hens. Hens are not good sitters. We had good sitters years back and lovely memories of baby ducks/chickens with mothers. What is your opinion on eating bucks? Here is my greenhouse I built last fall, bent hoops myself.

-

Thanks, lots of good advice and experience, wow you type fast. I picked up Nubians last spring and alpine in fall. The buck has never bucked me, if he looked frisky I would lay a stick to his ass to let him know who is boss. I don’t want a stinky drum skin so I will probably trade him. Good to know meat is good. I want to band baby bucks and maybe choose newborn to breed. The Nubian buck is dehorned and near 200 lbs. I dragged elm limbs every day to feed them, then got hay rolls last fall. They get soaked corn every day too. Good animals. Chickens too for last 6 years.

-

What did you do in the shop today?

Will-I-am replied to Mark Ling's topic in Blacksmithing, General Discussion

Worked all day around ground pit forge. Cut off 6” off tong reigns. Worked the edge of new anvil with 2lb ball hammer. Slid the material up constantly moving and rotating trying to draw out reigns. Switched hands from left hammering to right the whole session. Progress slow but learning. Transported 2 gallons of hot coal to smoker and about to eat 2 racks of 2 hour mesquite smoked ribs after forging done. Tired, time for a beer. -

Will make cone first and then cut out one door and add the other two as pass trough. Will smear fire clay and attach 12” pipe. Will help with general smokiness. Tips on bending with torch?

-

These goats are a year old 2 Nubian with star milker and star buck parents and 2 Swiss alpine mixes. One buck and 3 females hopefully pregnant. Enjoyed reading goat lady and frosty info. Need to rid of stinky male before babies born any day now. Should eat male? Need a drum head for newly chainsaw carved djembe but will meat stink? Could trade buck for more females. Spotted Nubian female will hop up and let me bucket feed her, preparing for future milking. Fat white swiss has fist size milk bag, kids soon.

-

Thanks for responding folks, progress as follows. Picked up dish this morning. Plenty of tin foil hat jokes with it transported on top of my truck. Real thickness is 1/8” and 9’ diameter. If you step on it it dents but springs back ito shape. Center aluminum cover was welded to mesh; used angle grinder to weaken weld then hammered chisel through, hard one hour of deafening pounding but only mesh left now. Edges rolled for strength. Have a brush burning torch to heat and bend maybe over log to get cone. So once cone is achieved heat up over fire pit then cool quickly with water, is that annealing?

-

Bois d' arc/Osage Orange/Horse Apple trees and wood

Will-I-am replied to Leather Bill's topic in Everything Else

Thanks for the info Glen. This 24”x21” diameter sycamore was incredibly heavy green; I could barely lift it off the ground, almost hurt my back, heavier than my 136lb anvil. I am excited it will dry to light weight. I have carved the djembe drum shell down to 1.5” now but still have to take it to 1” thickness to complete. Still weighs over 50lbs and 3 weeks since green. The important thing is to get the center hole made quick before cracking. Used 18” gas chainsaw to rough carve then axe and hammer. But 80% is with this awesome rechargeable 12” chainsaw with half dollar tip. Should finish her soon. I have 40 gallons of curly oily fluff that saw spit out to use as fire starter. Hope to forge weld 2 top rings to hold skin head. -

Tomorrow I am picking up a vintage satellite dish 7' diameter free from a friend. He claims it is 1/4+ thick aluminum mesh. I plan on using a reciprocal saw to cut with a 9 teeth carbide blade using wd40 as a lubricant. I have bent plenty of sheet metal but never aluminum. I plan on bending it into a cone with 1' top diameter and 4' bottom diameter, then drilling and bolting together seam. I understand aluminum cracks and do not want breaking to happen. I want to bend the cone first and then cut out removable doors later. Please share tips on bending without cracking?

-

Bois d' arc/Osage Orange/Horse Apple trees and wood

Will-I-am replied to Leather Bill's topic in Everything Else

A month ago I cut down a 23 inch diameter sycamore on my property. It grew this big after hogging sun and water for 15 years and shading out my garden, so I had to move the garden to a sunnier spot. That worked out for the better because I built a 17'x67' greenhouse over the new garden last fall. Sycamore wood is very hard and reminds me of ironwood from the east. Some of the limbs grow horizontally for 20 ft. The bottom round is what I am chainsaw carving my djembe drum from. The second round will be another drum and the third was the anvil stand. The rest of the tree will be many projects, hopefully many handles for forged tool heads. -

Cool advice folks. Since I am not lucky enough to have a drilled well for water, a water filter is super important. You can go for a while without food but water is different. Dirty water will kill you quick, but charcoal will help recovery. Two 5 clean gallon buckets stacked with a $100 fancy filter is a good survival investment. If the power was out for an extended period and the city water pump fails then I could hike down to the lake fill 2x 5 gallon water carriers (balanced load) and then add to filter setup. With clean water one can think clearly to hunt, scavenge or cook survival food. Collodial silver is a good survival medicine. Some complete gravity water filters can be had for $250 and they would be worth it. Alexipure is one company. Solar panel and battery are nice too for light. Hopefully rolling blackouts wont spread to the rest of the us.

- 102 replies

-

- introductions

- gas forges

-

(and 1 more)

Tagged with:

-

I already cut the jaws and boss in the tongs with the oversized stock, that was what I did the last few short forging sessions while I was carving a drum with my chainsaw. Drawing down the reigns will help me learn the much needed skillset and lighten the weight plus the cutoff 6" ends will be 2 more projects. The boss needs work on the anvil edge so it closes more smoothly. My daddy put a hammer in my hand very young, but I did not learn to hammer left handed until I built my house. I got to where I could hammer small finish nails lefty; the right is always more accurate. This helps minimize neck pain. Hopefully I will minimize future elbow issues by using both arms to anvil hammer.