Hawkbox

Members-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Hawkbox

-

I don't honestly know what those are, and google only gave me some weird Russian results so I'm going to trust you that they don't work well.

-

That tracks with local terminology drift, I think I described it poorly but it was very soft metal and didn't weld well when we used it. We got thousands of feet of it and made livestock corrals out of it. This may be the ignorance shining through but I'm struggling to see what you would use 3/4" or larger material for in common usage? It seems excessively big and difficult to work with anything that easily comes to mind. The picture attached is definitely the same stuff.

-

Looks good Deimos, tongs are on my list of things I need to address. Channel locks are ok but mine aren't very big and I've already melted part of the grip setting it on hot metal once.

-

That makes sense, one of my neighbours has a pair of old coil springs the garbage guys refuse to pick up so I may go see if he minds me disposing of them for him. I have the sneaking suspicion I should start with mild steel at any rate and start asking around. I don't have the tools handy to really do anything with a leaf spring or car axle yet so I'm not feeling terribly ambitious that way, I have a lot of tools I need to build and/or buy before I get to high on my own supply. I'm wondering if sucker rod is different in the US? Up here it's almost an inch thick on drilling rigs or at least the supply we have on the farm is.

-

It looks neat Twigg, so I'm impressed even if no one else is.

-

Yeah, something to build on. I need to figure out where I can get some known types of steel cheap locally, I found a couple metal shops but I think they're more industrial. I should harass my welder buddy too sometime about it. I found some chunks of flat iron in a metal dumpster so xxxxxx knows what the metal actually is but it's giving me something to beat on that I don't feel bad or wasteful using.

-

So here is what the inside looks like when it gets up to temperature and the colour i can get the metal to without any additional changes yet.

-

Nah I have half the ITC left, I was just curious if it was a good or bad idea. I may just suffer with the fire brick floor until I can get some kastolite and deal with the heat sink problems since I have it running and work on the other aspects first.

-

Well that's a relief, and probably just as much fun to troubleshoot this one as it is to build another one. If I get Kast-o-lite can I paint it over top the existing ITC-100 or is that a bad idea? Since I'm basically going to be multi layering the ITC right now.

-

Yeah I've got tedious meetings for the next few hours and then I'll run the forge and get some better video and pictures this afternoon. I do get a nice solid orange throughout when I'm using it but I definitely don't get a yellow in it. I'm not to worried about running out a propane tank in learning to get this right. You make a good point about taking the time to make this one work and getting all the way finished before I decide to go "squirrel!" and start another one.

-

Ok that makes sense, I just wanted ot make sure I was clear as the base level instructions I had were not terribly clear.

-

Neat, yeah it was a bright orange colour and I wasn't entirely sure if that was right or if I had them misplaced. One of those things where what people gloss over knowing already. To be clear, you're saying put the ITC-100 in a clear container, add water and stir it up cause it's kind of a paste, then let it settle out and then paint with what doesn't drop out over the existing ITC I put on previously?

-

I found a place in Ontario that will ship me a gallon of it for $20 which is a better deal, though if this stuff only has a 2 year shelf like as the MSDS seems to say I don't seem me using anywhere near that much. Feels wasteful.

-

I was about to ask how much silica was needed, a plastics shop near my house has something called Cabosil HDK® N20 that is fumed silica, I'm in the process of finding out if it's hydrophilic or not right now. Naturally they want $35 for 500g of it which is much more than what you're paying so I'll keep looking but I'm not expecting much, we get hosed on pricing up here. I'll reach out to the shop about the Plus and when they might get more or where I could get some, since they clearly have a supplier somewhere. Billy I noticed I could select subsets about 5 minutes ago, this is the only forum I have any involvement in that has an issue with quoting entire posts so I will endeavour to keep it in mind. Edit: Ok so that silica while overpriced will at least work from what I can gather. HDK® N20. HYDROPHILIC PYROGENIC SILICA

-

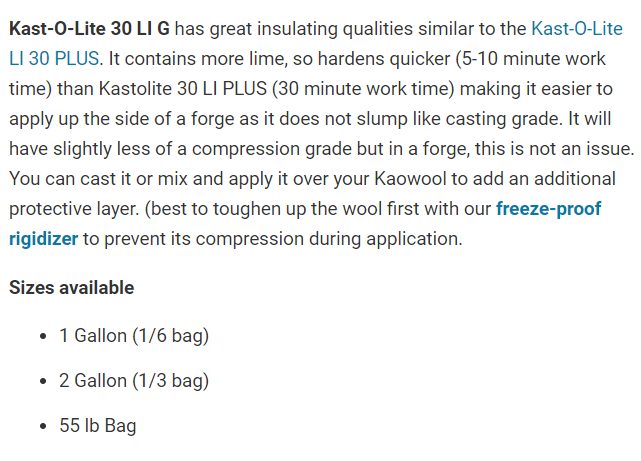

OK so I may have just been blind, they have something called Kast-o-lite 30 LI G and Kast-o-lite 30 LI Plus, they have the G but not the plus. This is the description they give, is there any major concern with one vs the other? The site is called Canadian Forge and Farrier if someone wants to google.

-

I have unfortunately, the ones local to me did not stock most of what is discussed here and the ones online are very vague as to what is actually in the material they're selling. I want to post a link for an example but I will probably get in trouble, let me see if I can take a screen shot. It's surprisingly hard to find these materials in Canada, which is really odd to me as when I am brewing I can get the materials, they just cost more. With this stuff it doesn't seem to even truly exist. I'm sure there is some place I've missed, but I've literally ran out of ideas. Advertising link removed

-

Dude... Buddeh... I never even considered putting an old iron on top and just letting it soak heat. That's genius!

-

I have my phone automatically upload them to dropbox and then I drag and drop them into the forum if that helps Horseman. You can see the pictures in the post I made yesterday, I'm very curious to see what you came up with as I'm already in the build another one with the things I learned the first time in mind.

-

I've spent 2 days reading through it, dozens of pages with random smatterings of information is not an easy or straight forward read. I am aware this forum frowns on new users posting things that can be found eventually but at a certain point I just needed to ask some questions. The reason I went with ITC-100 is that I've spent days trying to find Canadian sources of the other materials stated as preferred here without success, I understand the verboten nature of posting a link to a supplier directly but it makes it bloody hard to find anything. My local farrier supply occasionally stocks it but has been out for months now, I have not found a single other Canadian vendor that I can buy it from. We do not have the overwhelming amount of choice you in the US do, I've found numerous posts from Canadians previously trying to figure out ways around this and I never found one that succeeded. I'm not trying to downplay needing this material but please keep in mind when you're new to this you don't automatically know what stores stock what materials. I will probably end up having to order the material from the US with the exchange rate and customs or I will get ambitious in the spring and attempt to mix my own unless they get more in stock soon, which I have doubts. To the forge itself, I used rigidizer rather liberally but realized after I finished this that I would have been smarter to spray the rigidizer on while it was flat and then fit it in to let it dry, would have been a lot more consistent and probably easier. It would have been less stressful as I tried to get my arm down the tube while wearing an N95 and stressing out that I touched the material and I was going to kill myself with it. I put by far the most of what I thought was refractory (ITC-100) in the burner ports and I was wondering if there is a position on putting refractory on the burner itself. I have been adjusting the positioning to try and make it suitable, I notice though that the bell end of it gets orange itself and I can't imagine that is good for the long term health of the burner. Is that a positioning problem, normal, or me doing something wrong I haven't considered? Can I put Kastolite assuming I can find it over the existing coating or is that basically a one and done situation that I should keep in mind for the next forge? I'm not terribly inclined to pull the wool out and potentially stir up the fibres. They are 2600F rated fire brick in the bottom yes, I had made what appears to be a faulty assumption that you would want a hard and durable material on the bottom so you don't wreck it with the materials you're putting in. My interpretation of what you are saying is I may be just as well off insulating the entire inside with firewool and then building up a flat platform on the bottom out of Kastolite if and when I can find it? Appreciate the feedback, need to definitely do some thinking on the Mk2 forge idea. Edit: I guess it merges separate posts? This is replying to Thomas. Thomas, you are very correct about the safety, I keep all the doors in my garage open. I grew up working on tractors in poorly ventilated shops so I have an appreciation for not choking myself out. But I am going to go buy a CO monitor this afternoon, no point in mucking about. The forge and hammer are indeed room temperature, which here right now in my garage is 10C. I had briefly thought about that but hadn't really realized how much of a heat sink that would act as, I am assuming at this point since I've only been going for less than an hour at a time playing with things to try and line them up I haven't even brought the anvil anywhere near the same heat level before I call it a day and walk away to let it cool. I have a lot of secondary projects I still need to do, building a proper anvil stand (It's a tree stump right now that is not high enough), moving my bench grinder and drill press to where I can more easily use them, figuring out a permanent home for the forge that doesn't burn my garage down, etc... Most of that has to wait until I put my motorbike back together though, was doing a valve adjustment on it and finally got the parts in I needed.

-

The flame started coming up the tube with the burner I turned off, it took a while to melt but it did. I tried removing the burner entirely to see what happened, I ended up with a flame about 6" long coming out of the tube when I removed the burner.

-

Yeah that sounds like a completely valid idea building smaller burners, I did actually try turning the 1 burner off and it melted the tubing. I will look into it but I think I can imagine the chimney effect. I like how the T-burner as you called it works but since I'm still learning, and honestly building the stuff is as much fun to me as using it I will have to poke around for different designs and buy materials to do a few different styles to see which works best. Part of why I'm considering building another smaller one is cause I like building stuff and I feel like I learned from this one, but yeah modifying this one also works as a learning opportunity.

-

I was more being a smart xxx about that, but you make a good point. Only problem is I'm in Canada so that usually kills any of these forum deals.

-

I've got some extra fire brick I've been using to block one end and it does help, when I have some time tomorrow I'll try and get some video of it in operation. I've got some ceramic block I need to cut to shape as well, I was trying to make sure i didn't have anything done objectively wrong before I put more resources into it. Ok 30 seconds is normal? Good, I'm still mucking about and when you watch videos they tend to be a little fuzzy on exactly how long you can work the material before it cools. It is 3/4" pipe into the tank if that's what you mean. It's what I was able to easily get my hands on, they might be overkill but when you don't really have a baseline to compare against (The local blacksmithing groups are all shut down cause of Covid) it's hard to spec things completely accurately. The tubing is absolutely correct, I have been keeping an eye on the lines and they haven't gotten hot but it's definitely high on my priorities to swap it out. I was looking at capping one of the 2 burners for precisely the overkill reason, just have to get to the hardware store and get a pipe cap for it. My propane regulator doesn't have a gauge on it but it's 0-20 psi and I would guestimate I have it running around 5-8 psi most of the time so far, turning it up any higher and I end up with a big flame coming out the end and some coming up through the burner tubes. As for what I am going to do with it, not entirely sure yet. I played around a bit with farrier work in my early 20s around 2001 but went into IT instead and with the lockdown here in Canada I needed a hobby that didn't make me as fat as brewing does. I'll probably end up messing around with knives at some point cause that seems to be what everyone does but for now I am still looking around for good beginner projects too. Edit: I've also been working off a couple stools with fire brick to protect them while I figure out where to put it in my garage so I don't burn the whole place down. The picture in it doesn't have the fire brick yet cause I was monitoring how much heat went down first.

-

That's a very interesting question, I can line my next forge with Colgate maybe.