-

Posts

521 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jobtiel1

-

How do you store your metal ?

Jobtiel1 replied to Glenn's topic in Blacksmithing, General Discussion

It looks like a display rack for window wipers from cars. Those at least look quite similar. ~Jobtiel -

What did you do in the shop today?

Jobtiel1 replied to Mark Ling's topic in Blacksmithing, General Discussion

Today I've been doing some cleaning, and separated some of the egg coals from the smithing coal to test them separately, if the smithing coal in those bags is good enough I'll sort it all and sell the egg coals, too much of a hassle to use them. I've also been checking if the wagon wheel and wall anchor I got are wrought iron. I've been bend/break testing them but I don't know for sure what I'm looking at is wrought iron. I'm gone for the weekend so I left some pieces in cleaning vinegar to hopefully show the wrought pattern. The results of the break test, maybe someone here can more accurately identify it. This is from the wall anchor, which I believe shows that is is wrought iron. these pictures are from the wagon wheel. And the final piece is a piece of mild steel to compare against: Looking at this, I think that the wagon wheel is mild steel, what do you guys think? ~Jobtiel -

This link (it's in dutch) describes the local wood types and what they were and are used for. it also describes that Cornus Mas, (Gele karnoelje in dutch) was used for smithing hammers and spear shafts. Maybe some good information for other types of wooden builds you want to do and what wood you want to use for it. ~Jobtiel

-

What country do you think made the best anvils?

Jobtiel1 replied to Malleus's topic in Anvils, Swage Blocks, and Mandrels

Maybe it's a good place to talk about specific anvil patterns and what your favorite is instead of the specific anvil manufacturers. -

I always check the "readers for readers" part in the local newspaper, and yesterday someone wanted to give away an old wagon wheel for free. I drove there to pick it up, the thing was massive! It's about 140 cm in diameter. The guy also tossed in an old wall anchor he said came from an old restored church. He mentioned it being from around 1400-1600. So that should be wrought, and I'm hoping the wagon wheel is too! ~Jobtiel

-

"egg coals" for blacksmithing

Jobtiel1 replied to Jobtiel1's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I use a bottom blast with the Bob Patrick firepot, so there is just a small slot for that air to go through, some round bar with a few tack weld might work to allow the ash to get through the slot easier, I'll try it out, thank for the tip! ~Jobtiel -

"egg coals" for blacksmithing

Jobtiel1 replied to Jobtiel1's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Spending some more time with the stuff and there is a big issue, its the ash. after about an hour or two there is so much pent up ash that the fire becomes nearly to small to heat stuff up. I do remove it regularly with the rake but I don't have a good way to remove it all efficiently without disturbing the fire too much. I guess I can use the bags to practice working with dirty fuel more. ~Jobtiel -

How do you store your metal ?

Jobtiel1 replied to Glenn's topic in Blacksmithing, General Discussion

Well.. I have a dedicated corner for it to lean against, and a bucket for the small stuff. I remember HC steel by how and when I bought it, and it works fine so far, most of what I have is in spring form or in long hex or thick round stock. I do want to mark it all someday, but I haven't come up with a good system yet. ~Jobtiel -

What did you do in the shop today?

Jobtiel1 replied to Mark Ling's topic in Blacksmithing, General Discussion

Recently I got a speaker magnet for on my anvil too. i just stuck it on without removing the stuff around it, it works well enough as a dampener. Today a minion one of my friends came over to help me with some striking. I needed a big drift to forge the eye of a froe tapered and round. made one from 45 mm round C45 steel. First time forging this stock, and I must say it went a lot easier than I expected. so next time he comes over we will be making a set hammer. and after that or that same session a big fuller, both from the same stock. the set hammer I will be using to make bench dogs for his workbench. He also gave me a small wooden block plane, which I flattened out and sharpened the iron for. In the mean time he made some handles for some stuff on the wood lathe. All in all a productive day, but no pictures unfortunately. ~Jobtiel -

Most useful tool in your shop ?

Jobtiel1 replied to Glenn's topic in Blacksmithing, General Discussion

Angle grinder. I use that for most if not all projects. To clean up with a cup brush, grind with a flap disc, or cut with a cut off disc. ~Jobtiel -

What did you do in the shop today?

Jobtiel1 replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Unfortunately I didn't get the book, the price wasn't really right. I have noted it in case I come across it again for a better price. ~Jobtiel

-

Sichelschmidt und Schlasse (Sickle smith and lock)

Jobtiel1 replied to Zozon's topic in Anvil Reviews by brand

Very nice anvil! Congrats! And I agree, anvils aplenty, German pattern vises too. But forges, not so much. I'm still on the lookout for a proper hand crank blower! ~Jobtiel -

Those types of stores are the best, in our house, most of the breaker circuits and the entirety of the structural wood for the shed were recycled from building sites. A lot cheaper than buying it all new!

-

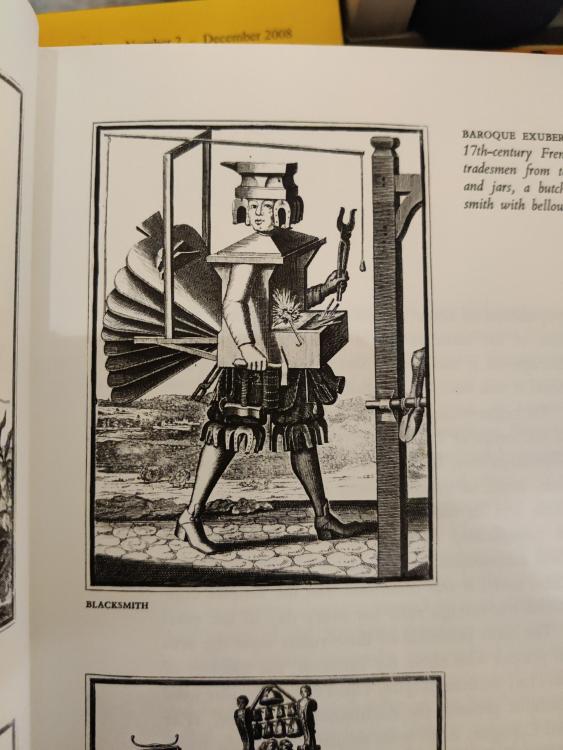

I came across this figure in the second hand book store. A very interesting ... representation .. I would call it. ~Jobtiel

-

"egg coals" for blacksmithing

Jobtiel1 replied to Jobtiel1's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

So, I've been using them for a day now, and they seem to work really well, upside is that there is a lot less smell and smoke compared to bituminous. There is however a lot more ash and fireflies compared to bituminous, and the whole workpiece was completely covered everytime. The eggs also have a tendency to block the airway as a lump. Some heavy poking to break up the eggs is also needed. I've got steel yellow hot and a little sparkling here and there, but I haven't tried to forge weld. It seems that the eggs have no trouble to reach that temperature though. I think lighting them might be a bit more trouble than with using coke from the previous day. We'll see about lighting them the next time. All in all, I think they work pretty well. And I can definitely use them to forge! ~Jobtiel -

Best Online Beginner Supplies (Tools/Stock)

Jobtiel1 replied to MaybeASmith's topic in Blacksmithing, General Discussion

I recommend finding a local scrapyard to buy a big block of steel to use as an anvil. And you can probably find stock there as well. What you need is also dependent on what you make. I think you can ask at your hardware store to order you one of those hammers and you can still get them for their price that way. Forge wise a JABOD is the most affordable way to start forging. If you're really set on propane I can't help you, never used that. ~Jobtiel -

"egg coals" for blacksmithing

Jobtiel1 replied to Jobtiel1's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Glenn, they indeed look similar to the charcoal briquettes, but they are significantly smaller, and often only sold by coal dealers. Its quite easy now for smallish amounts to be taken out and tested separately. the most important to me is to see if I can forge weld with it, if not, I have to go get some more bags of proper smithing coal to use when forge welding. Thanks for the info Irondragon, glancing over the report it seems to me these things are just a somewhat inferior coal with a binder, just to be able to sell the fines too. I test it out tomorrow and I'll share the results. ~Jobtiel -

Hi all, Today I picked up about 300kg of coal from a friend of mine who wanted to get rid of it fast. Completely free. Now, the coal is two types mixed, one of which I think is bituminous, the other chunks are called "egg coals" (translated). Now I looked up what that meant and it is said that these are coal fines pressed together. They break up easy, and I don't know if there is stuff added to keep them in shape. Do any of you have experience using this type of coal? Should I bother using it? I'm gonna try them out tomorrow, so I will of course also update this thread with my findings, as I couldn't find any other discussion on egg coals. Attached some pictures of what they look like. The egg coals: ~Jobtiel

-

Trouble seeing details in glowing metal

Jobtiel1 replied to IronChef's topic in Blacksmithing, General Discussion

I haven't really seen people use these kind of glasses both on here and with other local smiths, are you using them all the time? Or only during forge welding? I haven't really considered IR radiation from hot steel, but I've made it a habit not to stare in the fire. Do you still recommend getting these kind of glasses over normal safety glasses? And do you guys use them all the time or just for forge welding? ~Jobtiel -

Yeah that thing is a shoemaker's anvil. They are everywhere around here. the ones here are nearly all cast iron. ~Jobtiel

-

What did you do in the shop today?

Jobtiel1 replied to Mark Ling's topic in Blacksmithing, General Discussion

I advised some of the older scouts and their guides today on doing some aluminium casting, making sure it will work and emphasizing the safety aspect. We dried some dirt over the campfire to pour the aluminium in, and I welded up a steel crucible to melt the aluminium in. Some guys dug a hole and with a hair dryer and some charcoal we did a few pours, nothing really worked well, but they found the flaws in their designs and in a few weeks they will try again. Very fun day! My own group did some runs on an obstacle course we worked on the past week. ~Jobtiel -

Ah that makes a lot of sense actually, thanks for clearing that up! ~Jobtiel

-

Yeah, I think that will really come in handy, looking around it seems that the company has fused, so the original name is not there anymore,. It the new company still produces torches. There is also some other part in there that I don't know the use for, maybe it doesn't belong in there at all. At the end of the small rod there is a point, and there is a place for a second rod in there. ~Jobtiel

-

The torch is from a company called Oxygenium, based in Schiedam. The part labeled from Sweden is part of some other set. Haven't looked around much yet, but iirc correctly the one my brother uses on his work is from the same company. ~Jobtiel