-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ah… but not sure what I need to practice! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Just finished asking some place and was very politely told, “we do return our oil to a local gas company each month…and that company actually sends us a check in the mail each month as payment for that oil. Due to this, we unfortunately would not be able to part ways with any of it.” Of course, what the gas company pays is probably next to nothing, but it is what it is. Guess it’s on to the next try. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I appreciate the advice. I’ll try to find someplace. Just not sure if I can before this weekend. We shall see. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

John- were you suggesting that for acquisition or disposal? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I was planning on doing a torch temper or using a heated steel block. I figured that not even the dog would appreciate motor oil in the house. I considered the route of asking some place for oil but wasn't sure how to go about it. And also wasn't sure how to dispose of said oil when I am finished. However, it seems that that is going to be my best bet, so I'll try to find somewhere. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Amazing as always, Alexandr. Your work always blows me away. I spent a few minutes yesterday making a bonfire to roast some keilbasas and anneal some leafsprings. I'm preparing to make a broken back seax and maybe a couple squirrel tail knives with a friend this weekend. My first time working with 5160, and first time doing a blade this large, so it should be a lot of fun. While most of my blades I quench in canola, I simply don't have enough for this seax. However, I have plenty of used motor oil. While I've heard plenty of people say not to use old motor oil, I've also heard others say it's ok. I'm operating under the assumption that it is far from ideal. However, if I were to use it, (with a respirator- don't want lead or zinc) how bad might it be? This does not have to be an excellent quench. As long as it passes a file test and is relatively tough, I'm alright. I really don't want to spend any money to get more veg oil, as I don't plan on doing blades this big on a regular basis. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Looking good! Make sure to keep a light oil coat on it when you're done grinding- im not sure from your pictures whether that's scale or rust, but you definitely don't want rust in your final project -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ok. I’ll see what I can find. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Frazer, would some mower blade work for the body, the a 5160 bit? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

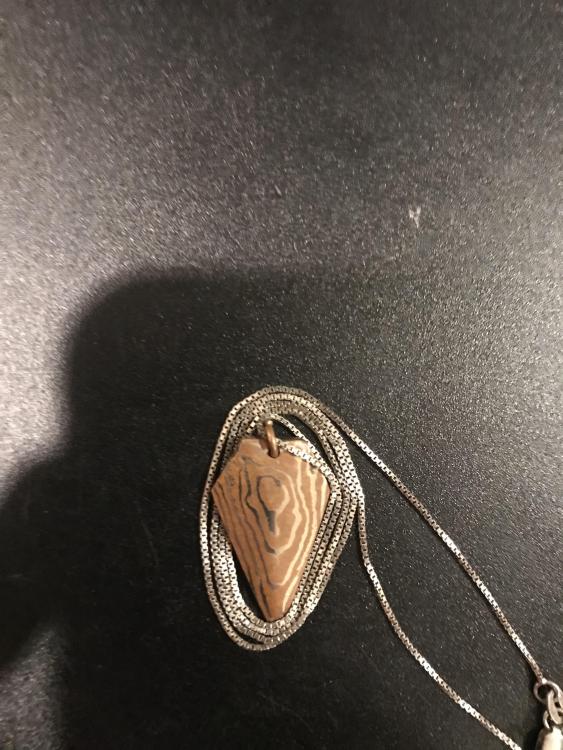

Well folks… long time no see! I have been away from the forge (and all of you) for far too long! I recently got these two pieces of mokume finished up. I made the bottom one with a friend, and the top one is a very small, dainty one I made for my mother. I ground down the edges (a bit like a knife bevel) on it to reveal the pattern a bit better. It was greatly assisted by my new belt grinder which I hope to use to make some squirrel tails and possibly a seax in the near future. I would also like to try a wrapped eye tomahawk out of some leaf spring. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Dax, that’s gorgeous! I might have to try that on my next knife (after some practice). -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

As a boy I made a few knives out of bought blades and antler tines. I used partial tang blades that extended anywhere between one and three inches into the antler and were set with two part epoxy. After a decent bit of abuse, they were all solid. Especially if you pin it, two inches should be fine, three or more excellent. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

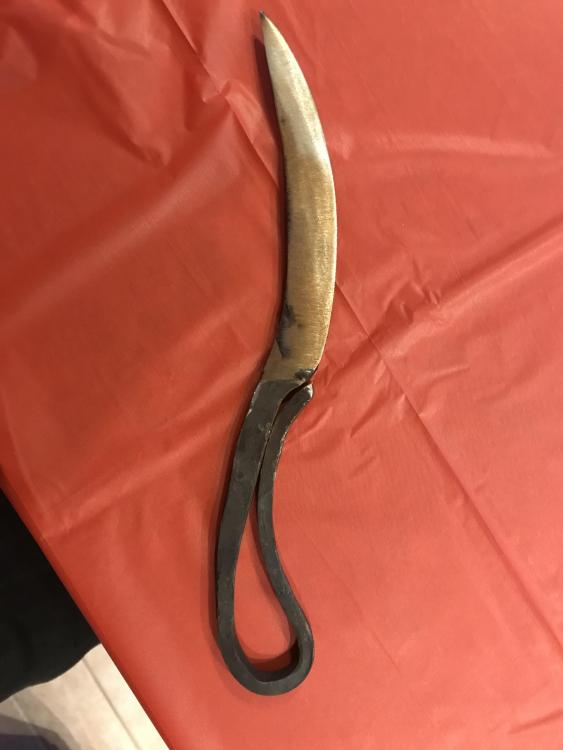

Thanks. I was frankly shocked by how well it turned out. Question is whether I can replicate it. There are a couple things I’d like to change on the next one- do a different twist style, make the choil much smaller (I didn’t have a needle file when I put it in), do a better finishing job, scroll the end of the handle, and try a more complex spine art. Then of course fit and finish. Overall though, I’m quite pleased. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Despite being insanely busy recently, I got to get out to the forge for an afternoon and make my first knife that I’m really truly proud of. About 2” blade, 4.5” overall. Made from scrap hex shaft and quenched in water. Includes my first twist and my first try at file work on the spine. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Tried to do a squirrel tail, started on some mokume. I think the forge built up a massive clinker, since it slowly just died out. The squirrel tail still needs a ton of work, and the mokume has a delam straight through the center. Too ashamed to post pics now ;). Maybe if I figure out the delam, and when I finish on the knife. Want to try cable Damascus soon, but it sounds like a massive pain, especially with coal. -

Believe it or not, I’ve never had an AG wheel shatter. Probably part of it comes from the fact that I always get the thicker ones, so they’re not as high risk. I do always wear PPE, learning from the time a piece of dremel cut off got lodged in my chin (I was still wearing safety glasses then). I imagine a shattering AG is no fun.

-

Unfortunately, I’m probably going to end up doing it with a 4.5” AG

-

Got some good stuff in the past couple days. Neighbor had a tree cut down and I made a big upgrade in anvil stands. Went from two rotting pieces of pine strapped together to a several hundred pound maple log. Has plenty of room for my eventual anvil upgrade. Visited the scrapyard for the first time and ended up with 140 lbs, mostly leaf spring with a big coil, some cable, and a huge file. Ended up costing $0.50/lb. more than I would’ve liked, about what I expected. Should last me a very long time once I break it down (a task I do not look forward to. Time to get an abrasive chop saw?).

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

The trick is to get a "one mile anvil": that is, one that weighs 5,280 lbs. They'd need a fairly large crane to get away with that! Upon further investigation, JD Napiers 6500lb anvil would also suffice. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Sindoc, pnut, I feel ya guys. It’s hot around here. Yesterday, while looking up the weather, I accidentally put in the name of some city in India. Today it’s supposed to be 109 there, with very heavy pollution. Maybe my 85 isn’t so bad after all… -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ted- I dunno what it is, but something about that just lit a spark in me. I absolutely love it. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

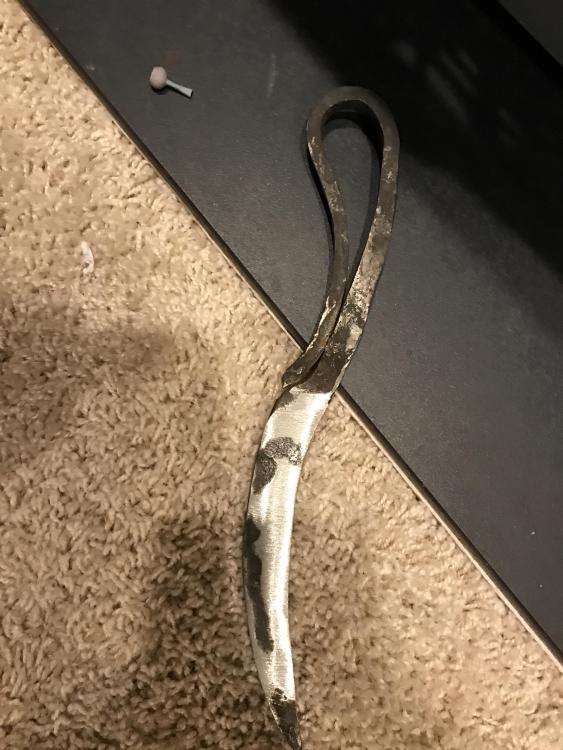

Did my first real knife grinding. Hard work, but I think it turned out alright. Got it ready for heat treat! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Alright. Thinking about it now, I realize that you can't really brass brush such a large piece. However, it is perfect for highlights, such as on that fireplace. If you have not already, you may want to look into it for accent work. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

alexandr- how did you color the chandelier? Is it painted, or brass brushed or something else? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Been really busy. Tried my hand at a squirrel tail knife. Alright in the forging process. We’ll see how the grinding goes.