-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Wonderful, thanks for the help. I just took a guess at 3/4, and obviously I was very wrong. I’ll probably try to find a 1.25”. That’ll probably be too big for my small fingers, but just right for my friend. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

My apologies, I thought that was a “hammer grip”; however, I am very likely wrong. One of the major flaws with this one is that the hole is too small to accommodate the index finger- only the pinky -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Diluted the acid for the cable, and it already seems to be better -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Goods- I think I’ll dilute my ferric a bit and try instant coffee if/when I get a bit of texture. Thanks for the suggestion TP. BK- those look great!! I think I’ll try another one soon with a shorter handle this time and a taller, thinner blade, along with the bigger finger hole. I think that might help the fit. Obviously this one is my first try and the next will be better. Here’s how it fits in a normal grip. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Forgot to post after forging a few weeks ago- I know this shape is a little impractical, but I just let the metal do what it wanted and had fun. Forged from leaf spring. Then I had a friend ask if I could make a karambit. Here is my first try at it, with mediocre success. Forged from 3/4” wrench (friend is a mechanic). I think I’ll try again with a 1”, as the hole was a little small to get my index finger in. Finally, I got my first real success at making cable Damascus. Originally 1.25” cable. Forged down to about .5” round. I’m really struggling to get a good etch on it. I’m trying 40% ferric for 18hrs, and that does something but not much. Maybe I just need to leave it longer? Finally, my brother is in town, so over the past couple weeks we made my mother a garden trowel as a late Mother’s Day/birthday gift. This is probably my favorite project I’ve ever done. It was a big challenge, but here we are. The handle is a piece of wood turned spalted tamarind, with a forged and brass brushed blade. It's all finished off with a blue patinated copper collar and a leather loop. We started by trying to use a piece of 1.25” round bar and work it like a giant leaf, but that didn’t work so we turned to a leaf spring. It’s thicker than I want, but overall I’m very pleased. Sorry for the super long post -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

George, that was kinda what I expected. But would it still be worth it to harden just so it lasts a little longer? I do have a little bit more complex design worked out, but I would probably outsource that to be made with a cnc edm. This one was done only with a dremel cut off wheel, plus a couple minutes on the belt grinder just to clean it up and taper it -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

no forging, but did some grinding. Finished up my most recent knife with a cypress (or cedar. Can’t remember) handle. Unfortunately, one scale cracked but the other side is good. also remade my touch mark. Same fractal triangle design, just cleaner execution. Old on left, new on right. Do you guys harden your touch marks? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Got my second one finished from the other day. This is my first try at something of this style- I was going for a kind of bird and trout thing. Next one definitely needs to be a little thinner with a broader handle. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy, I really like those! It's a nice minimalist style! Alexandr, you always amaze me! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Got a few hours in today, and it went pretty well! While I burned one project, I’d just started it, so it wasn’t a biggie. Other than that, I felt I had really good fire control all day. I got a few knives done. I really enjoyed doing this blacksmith’s neck knife, since the only grinding is in the edge. All profiling and beveling was done by hammer. Cutting edge is about 2.25” -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Simply beautiful alexandr. Your work always blows me away -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Very nice. Is it welded together? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Only thing I can think of is a really big grinding stone, but it would just be easier to get a belt sander. I've got a little WEN 1x30 from home depot, and while it is a bit slow it gets it done and only costs $100. I'm sure you could make some kind of rounded piece that can be bolted onto the back plate, giving it a radius. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I like it! What thickness bar stock is that? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Well most of this is grinding. There was very little forging in this piece. Hopefully my next one will have more. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

It's got me wanting to make EVERYTHING from WI now! This was my first experience with it, and while it was a massive pain, I am ecstatic with the result. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Maybe I'll try that with the next one John. Thank you for the wrought iron in the first place. Sorry it took me so long to get up the nerve to use some. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

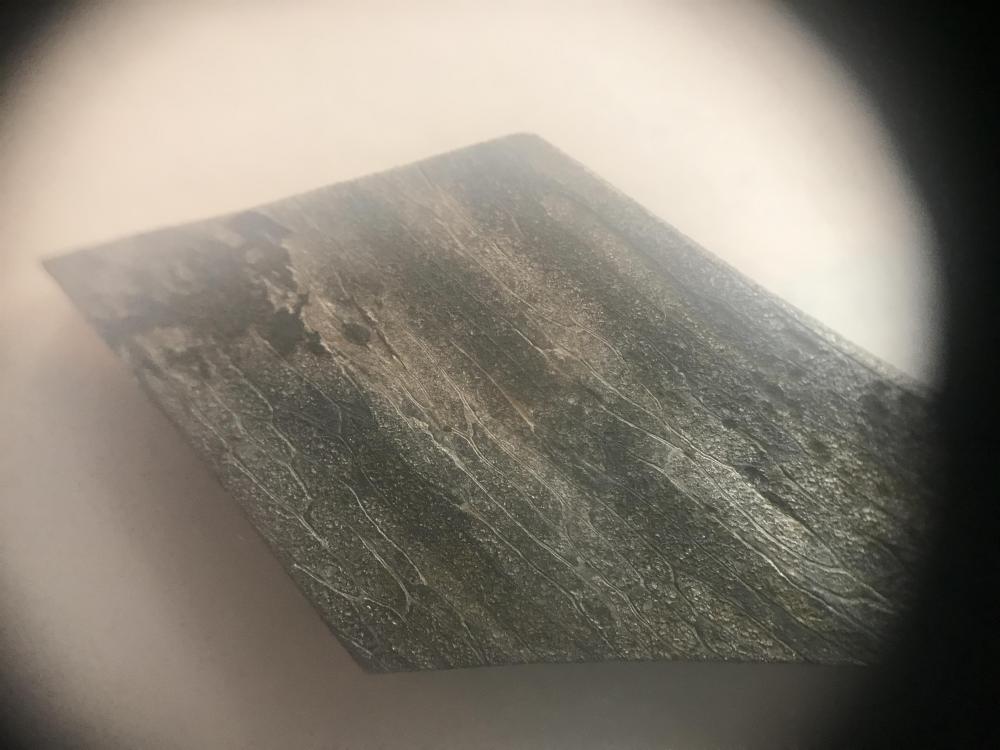

Finished! After about 5hrs of etching in 20% Ferric, I just touched the high spots with a wire brush. That’d be great, if you’d like to! While most of my points are authentic Native American, I do have a small number of modern points. The modern ones are nice because there are many varieties that are just too rare in Ohio, and it’s hard to find good condition stuff. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I’m not sure how the other household residents would feel about that… does 40% ferric work? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Cool, I’ll have to try that on my next one. Little sanding drums worked great but then the sandpaper would explode. The cones look like they wouldn’t have that issue. I’m pretty happy with how it turned out. It could be better, but this is my first try (except prototypes). Now I just need to etch! Are there any tips for etching WI? For example, how do you need to clean it before the etch? Thanks! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

That’s very nice das! I got it mostly ground before the grinder caught and shot it across the workshop. I’ll try to find it and finish grinding tomorrow. Speaking of which, the dremel takes a very long time when using one of the little alumina oxide grinding cylinders. Do you have any recommendations for a different grinding method for future ones? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Unfortunately not. After a few tries I can typically knock out an acceptable chert side notch head, but nothing exceptional. I’m also very out of practice. I have a small collection that includes some beautiful points, all made by people far more talented than myself. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy, I think they both look great. While I’ve been out of town the past couple weeks, I had some time today. I finally started using one of the pieces of wrought iron JHCC so kindly sent me several months ago. It needs a bit more work at the neck, then I’ll facet it with a dremel. I’ve got some ferric coming on Tuesday, so hopefully itll etch up nicely. I plan on making a whole set from different materials and then making a nice little case for them all. I’m thinking WI, mokume, ebony, chert, obsidian, Damascus, and timascus if I feel expensive. Maybe a couple other plain metals like copper, aluminum, and bronze. Might take me all summer but I’d like to make it happen. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I wood love to have one. I don’t see any leaves though. I’d still stick it in my dining room. Lovely piece Alexandr! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

That's lovely! What an incredible room (and I assume house) all around!