-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ok, gotcha. This robot is named Midas. Once we finish painting, it will be all maroon and black with the end of the arm being gold. Still lots to go, but it's coming together. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Neat. What was the axel for? While I'd love to make something for the robot, I haven't really found any good applications. Casting would probably be more likely to come in handy, but I don't have a foundry set up. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Not exactly "my" shop, and no blacksmithing, but got a robot to start working. Competition is in a few weeks, so we better finish up fast. Apologies for the shaky video. Finished my second fillet knife. Will get some pictures tomorrow. IMG_1006 (online-video-cutter.com).mp4 -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Lookin great Goods. Can't wait to see the finished product. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Sorry to hear that JHCC, those are a pain. What do you make with stuff that thin? I have a ton of maybe 1/8-3/16 garage spring. I made a screwdriver, but don't know what else to make from it. I guess little hooks and hairpins could be neat. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ok. Nicely done. I don’t have a fireplace but I’m inclined to try making one, even if just as a gift to a family member/friend. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Honestly, now that I think about it, I'm not sure either if that's a scarf. We need an expert for the nomenclature. What I was really trying to ask is if you folded it over and welded it, since I know most people do that while a minority ends up chiseling and splitting firepokers. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks brilliant to me indish. Scarf welded? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ok, thanks for the tip. I like all forging, but I'm just bad at it so I end up making lots of knives haha. I'm hoping to get more diversity in what I make once I have more time -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

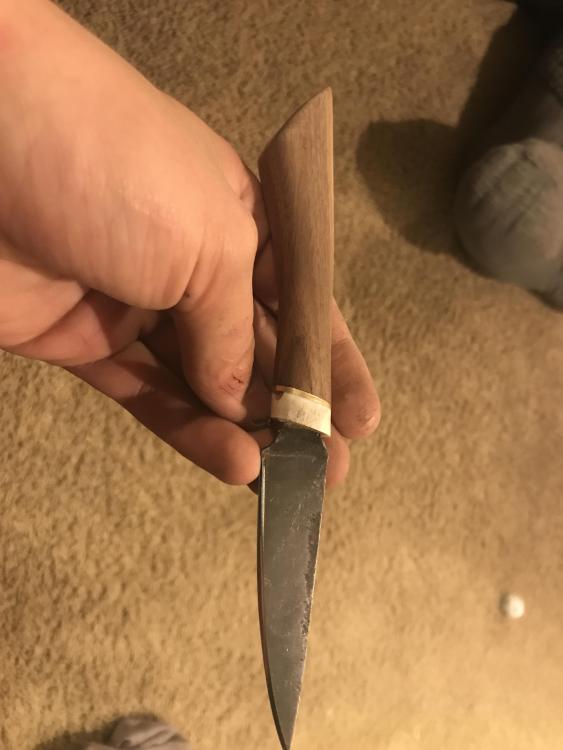

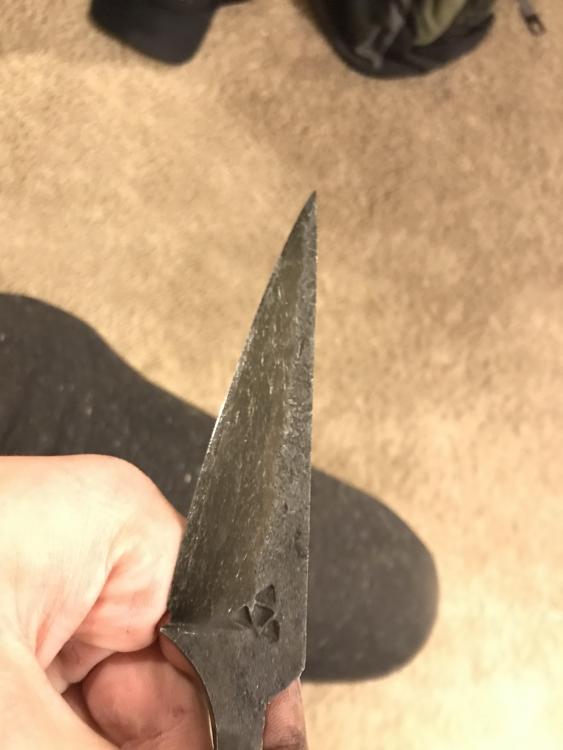

Alexandr- stunning as always. Les and Goods- very nice knives, I like the shapes on those. My dear people- Too much to do, not enough time! Got my new anvil a month ago, and still haven't used it. Hopefully will be able to forge soon. Did get a little time for some stock removal however. Started using bandsaw blades from work (machine shop) to make fillet knives. Here's the first one. Tried it yesterday on some bass. It's a bit short, but does a great job otherwise. Will finish the second soon, it's quite a bit longer. Kept the original heat treat as I didn't want to heat treat something less than 1/16" thick and 10" long. Also finished and sold this forged hidden tang with walnut and antler. A friend is going to give it to his son for his birthday. Starting to get a lot more confident in my forging, grinding, and leatherworking. Since my new anvil has a hardy hole, I need to start fabricating some tools. I believe it's 5/8", so I think RR spikes would fit it. Any ideas on what I should make? I don't weld, but I can probably have a friend do some welds for me. I'm thinking a hotcut, bottom fuller, something for bending, and a holdfast to start with. Started to draw up designs and prepare for my biggest project yet, a 26" short sword from a nicholson file. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Das. Clear is probably wise, don't want rust. I like the steampunk mechanical look, but a daughter is hard to trump. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Personally I like the bare steel, but that’s just preference -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Had my first sale yesterday. Two hidden tang knives of $75 and $95. Three pairs of mokume earrings for $25 apiece. Quite happy with the results. My new anvil came today! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

That's a good looking hammer. Have fun with the handle! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Pat, an observation- the leafy one looks quite like California, at least to my tired eyes. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished up a full tang and started on the handle for a hidden. Bought myself an early christmas present of a Vevor 66lb anvil- definitely a step up from the 12lb RR track. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Hope you’re feeling better pat. I love the lily. How do those bookmarks work? They look like they might be a bit thick, but can’t get a good view via phone screen. Those look like they could be fun in cold worked cooper -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

DHarris- was that welded or drifted? Looks great either way. I’d really like to make a hatchet but the last time I tried was a disaster and I don’t feel like reliving it. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Relocating? You’re passing up a good dinner! Got one of my full tangs finished up with a bit of mahogany. Got one with cherry rough shaped, and a cute little stonewashed hidden tang with walnut, brass and antler glued up. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Gotcha. I actually have a couple of those swaged portions myself and was unsure whether they would work. It sounds likt the answer is yes. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Blue rooster, that’s a clean cable billet. If it came from the same size as is next to it, I’m astounded. All mine have been dirty, rough things about half the thickness of my starting stock. Let me know how it goes to use it- I can’t for the life of me figure out how to etch mine. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Got a couple full tangs heat treated and handles glued and pinned. Started playing with stonewashing and I’m in love. The etching hides my bad grinds, then the tumbling hides my bad etching! I also love how subtle the forged flats look. There’s still contrast, but not so much as to make it feel discontinuous I’ve also done copper jaws. In addition, I fabricated some out of scrap 1/8” Al and 3D printer a pair. Those are all very useful for different things. Could also do plywood. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks shain. I think they’re very technically simple; probably why I make them ;). I still manage to screw them up though! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks les. I feel really stupid, both of those top ones I’ll have to re heat treat- they picked up warps that I didn’t notice in my rush. I think they’ll be fine though once I get them straightened out.

.thumb.jpg.787f029cf15c78bac98447fbf0de453f.jpg)