-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

He’s a gray tree frog, so very likely the same kind you have. I picked him out of my yard a couple years back and I’ve had him ever since! Khublai is a bit younger, as I caught him this past summer and he’s still not full grown. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Josh- wonderful job! I’m very impressed by how symmetrical you got the pieces. It looks like some kind of calipers, maybe? But then what’s that center piece? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Cleaned out my coal forge- looks like I had a failed mokume at some time, but I don’t remember it. Anyway, it’s a really cool piece- looks like it’s probably cupronickel- too golden for copper, but I cleaned the forge since last time I used brass. Could have just missed it then, though. Weighs about 50 grams, 1.77oz. While not as much “in the shop” I spent a couple hours rebuilding my frog terrarium after I found some fungus in it. Meet Napoleon, and Khublai (as in Kahn) is hiding somewhere in there. -

I used this bandsaw for a while before I was given it- i don’t know if it is just low power or if the motor is going out, but it definitely bogs down much easier than my friends dewalt portaband. I do have a new blade for it though, so I’ll try cutting some steel. Even if it doesn’t get steel it should work for non ferrous metal, wood… oranges. And the occasional grape fruit!

-

Got a bandsaw- it’s small and underpowered, but it was free! I imagine it’ll be very helpful for cutting handle material, but I’m dubious as to it’s steel cutting capabilities- even with a fresh bimetal blade and some coolant, I think it would inevitably bog down

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Das- that looks great! I’m trying my first cable Damascus and have had, shall we say, limited success. I’ve got a piece of 1/2-5” cable that is somewhat welded in some areas and a slag heap in others. Not having a welder is a bit of a pain since the ends exploded on me. I think I’ll pop it back in next time I fire up the forge and try to get it straightened out and welded better, then I’ll grind off the outside to see how it’s welded. I really hope I can get at least something out of it. My next attempt I’ll probably try a piece of 1”. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I hope that this is all gone by next January, then I can buy some more! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I suppose so! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Sorry to disappoint you gentlemen, but I’ve got 80lbs of leaf springs and cable by my woodpile- this is just for smaller pieces that would get lost there. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

While no forging, I made an overly sturdy wood box out of some scrap wood to hold my high carbon steel- I’m pretty sure this thing could contain an atomic blast. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Tw- lovely crosses! I thought they were wrought iron. I really need to figure those out. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Knocked out this little drop point for someone who got his Eagle Scout award. I think it might be my best yet- clean grinding, smooth lines, I remembered to use my touch mark, wonderful heat treat - I really like it. I think I’m going to do an upswept skinner with the same style handle soon. I just need to keep working on my grinding, and I need to make better things. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Useful tool, AND fun toy- all in one! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Had family in town and a cousin wanted to forge a knife- mainly for throwing, but still with a blade. Here’s a quick and dirty one we forged out of some leaf spring. 3/16” leaf spring, oil quench, with a heated block temper and a concave grind. A simple leather wrap gives it enough bulk to use as a knife but doesn’t impede throwing. While it’s tricky to get a good throw (like any throwing knife) it will embed up to an inch in pine logs. It was really fun making it, and I’m thrilled with how it turned out. One more step towards making a halfway presentable knife! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Loafers, that’s gorgeous! Very clean work- the hooks look identical, and the rack is symmetrical. Great work. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

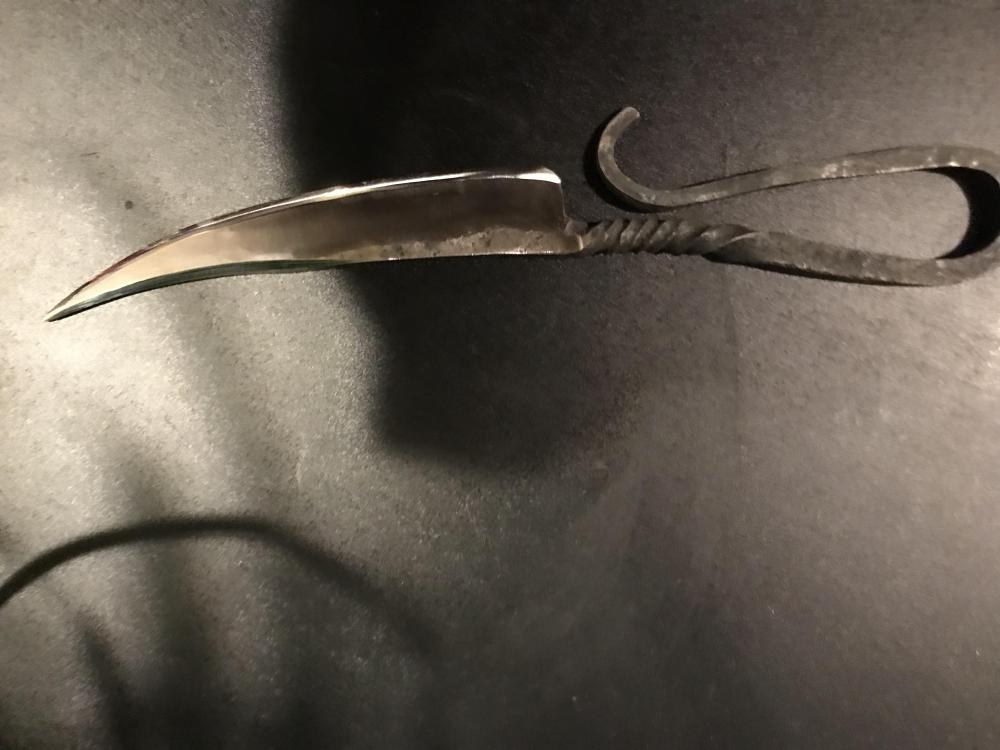

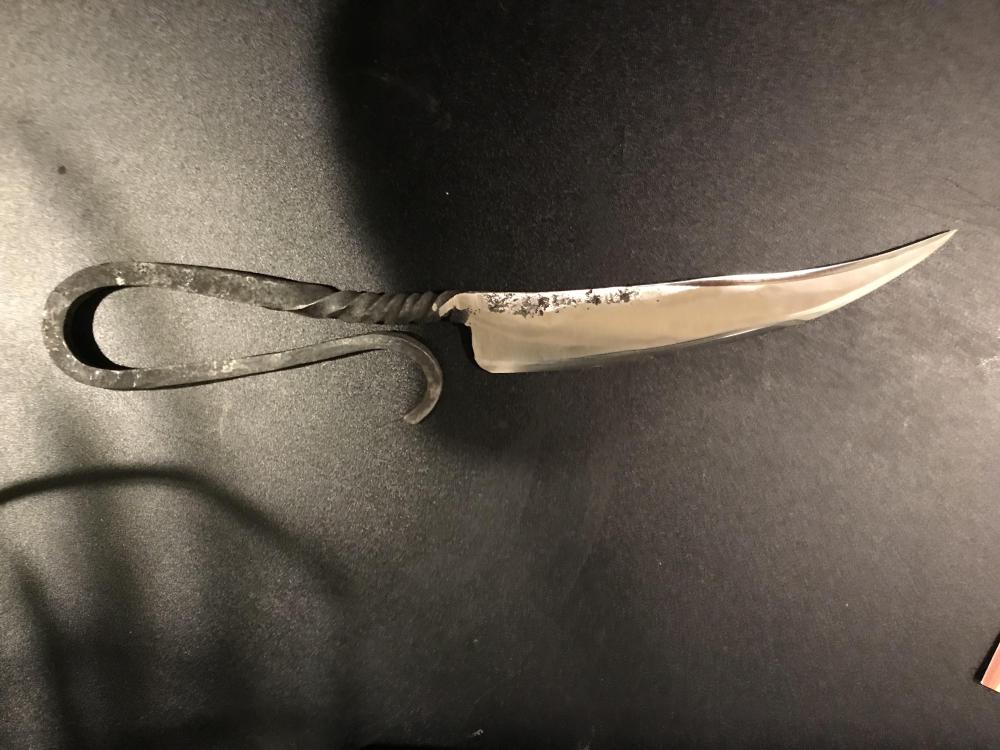

Everyone’s got such beautiful projects! While not as nice as your guys’ stuff, I finished up this clip point/slim Bowie. While it’s hard to see, it’s got a false edge and a hammered spine. I’m really happy with how it turned out. No hammer marks where I don’t want them, pretty sharp- I just need to make a sheath! Over these coming months I need to do a lot of practice grinding- getting nice bevels is tough, especially on hardened steel!!! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Merry Christmas everyone! I received a lovely leather apron and a grinding respirator, along with some new belts. I’ve got a squirrel tail clip point/ slim Bowie that I’m finishing up. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Got a little squirrel tail finished up out of some leaf spring. I have another one forged out that I need to finish grinding. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I’ll have to keep that in mind. At the moment I am just working at it with a dremel, though. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

On the topic of hammers- my go to is a stubby handled 4 1/2# rounding/hand sledge. It typically takes six or so hours for me to get too tired to use it. Luckily, I don’t forge much longer than that on any given day. for lighter work I use a 2# ball peen. SinDoc- what really confuses me is that all the wiring is covered, so nothing could have nicked it. I guess I’ll figure out what happened when I figure out where it happened. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

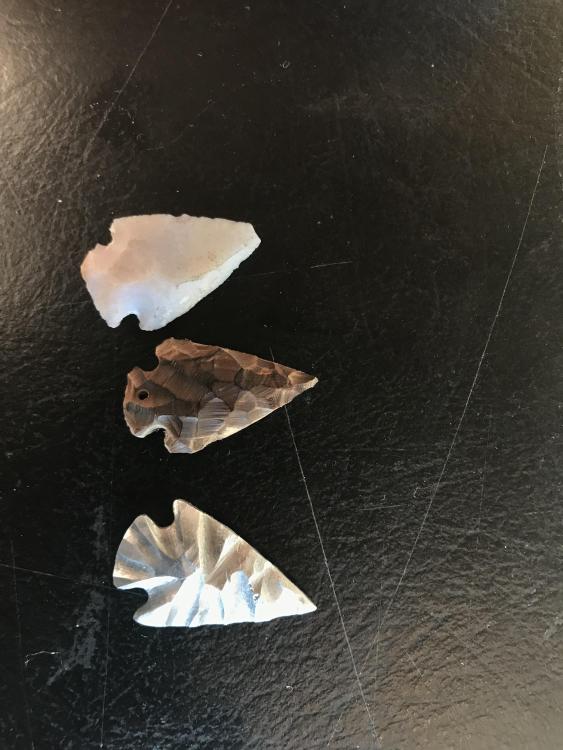

While no forging recently, I made a few arrowheads- one stone, one wood, and one aluminum. I need to make another aluminum one, since this one did not turn out. They are proofs of concept for a Damascus or mokume necklace. I also managed to screw up the whole wiring on my workbench- there’s a short circuit somewhere, so I’m currently running an extension cord from the house. I’ve started to tear it apart to find the short and fix it, but I’m a little low on time at the moment. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Maybe it’s just me, but I think melting 3” of steel qualifies as a mistake Maybe I can forge it into a happy little tree? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

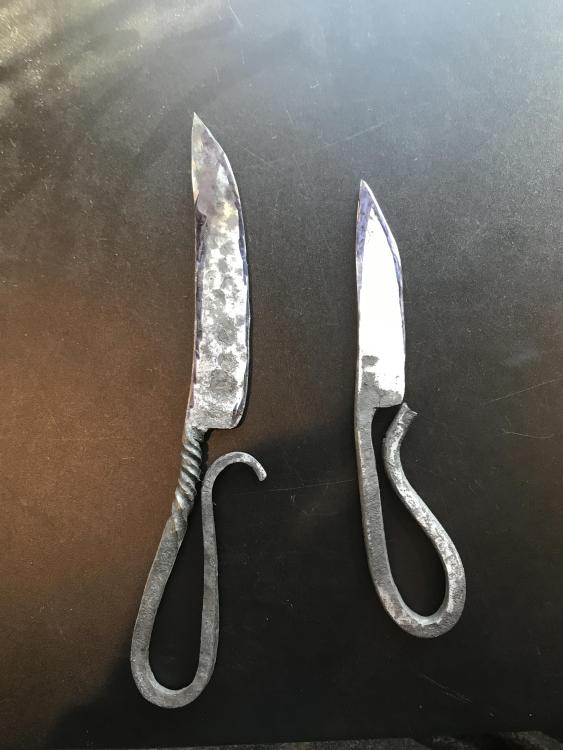

My first heartbreak- my friend, who was supposed to be working on this seax (it was almost ready for hammering in the bevels!) got distracted and it burned. Second heartbreak- as we were getting ready to cut off the tip (try to salvage some of it) it fell and snapped.Third heartbreak- while working on the new replacement seax, he cooled it off in some water. This is 5160. It cracked immediately . I’m not sure where I put that one. This was mostly my fault, since I apparently didn’t stress enough the importance of not water quenching and not burning the steel. Thankfully, we did manage to pull off a couple of squirrel tails. Mine on the left, his on the right. This is just forged and rough ground. Still lots of refinement to blade shape and getting good bevels.hopefully these will turn out well and we’ll get to do that seax soon. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, I much prefer yours. The first one looks like a distorted ampersand, whereas yours have the beautiful scrolls and curls I’d expect from a treble clef necklace. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Makes sense. Are smaller, mom and pop type places usually better? I imagine they would be less likely to have a contract. At least not a strict one.