-

Posts

535 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Cincinnati OH

-

Interests

Fishing, Reading, Animal Husbandry, Forging, Bladesmithing

Recent Profile Visitors

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes, it was certainly a big mess. Many people don't realize just how long the egyptian empire lasted. The actual empire went for two or three times as long as the Romans and certainly had complexities throughout that entire time (nevermind the period before it was really an "empire")I read a book called The Last Man Who Knew Everything about Thomas Young, a polymath who was one of the people to really crack heiroglyphics. One other "egyptologist" translated a group of glyphs as such "The protection of Osiris against the violence of Typho must be elicited according to the proper rites and ceremonies by sacrifices and by appeal to the tutelary Genii of the triple world in order to ensure the enjoyment of the prosperity customarily given by the nile against the violence of the enemy Typho". Who knows what that is even supposed to mean. Turns out it was simply a cartouche, the name of a pharoah or other important person (don't remember who precisely). The previous guy had just made it all up. I'd forgotten about Atenism. Fascinating period. My understanding is that Egypt was never truly monotheistic under Amun-Ra, but rather Amun-Ra was thought to be so powerful and important that the other gods were considered to be minor deities of little importance. Frosty, what are your thoughts on the triangle M? Just trying to get opinions on different options. I also tried a smaller M inside but I like this version more. I personally like either this or the AMON, but would appreciate others' inputs before biting the bullet. Both have some merits. Aamon is also a demon described by Johan Weifer in the Pseudomonarchia daemonum in 1583. It is described as having the "likeness of a Wolf, having a serpents tail, [vomiting] flames of fire". The name is adapted from the egyptian Amon and/or Ba'al Hammon of Phoenicia. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes, the egyptians loved to mix things. For example, Amun was a very old deity. Then they moved over to ra as the king of the gods, and eventually just mixed them together to form Amun-Ra. Some egyptologists have even suggested that it could be considered a largely monotheistic religion during the period of Amun-Ra, as he was so much more important than any of the other gods. Similarly they'd throw Amun on as a suffix, like you pointed out. My initials are AKM but my last name starts with Mon which is why I was considering that. My understanding is that Amun is a more common spelling but Amon is also widely accepted. I have been exploring the M inside a triangle idea as well, I think it has some merit. Not certain what you mean by this. Could you expand? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, I will probably order some online. I’ve looked into custom vinyl ones. Still trying to decide on a logo though. I think my last name is too long, so I’m trying to decide what they should be. I’m looking at my initials (AKM), AMON (first initial and first few letters of my last name, also Egyptian King of the gods before ra) mor a more abstract logo. I’ve been using a basic Sierpinski triangle as my touch mark. May continue with that but wondering if it would be easier to trace words/letters back to me. Open to any suggestions. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a redneck electro etcher. Not variable or anything, but it does a good job (forgot to get pictures of any of the test pieces). Thinking it probably shouldn't be too dangerous, but we'll see. Need to order some good stencils now. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

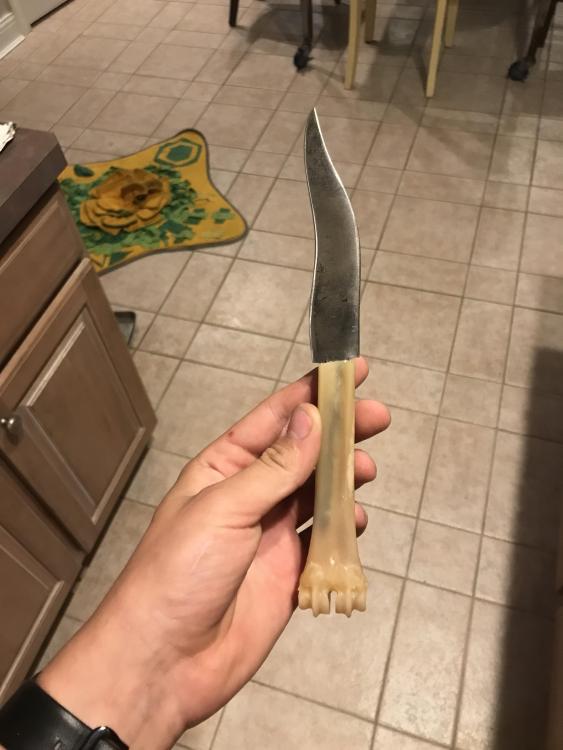

Nautilus is looking great! Did a bit more work on this one… bone still needs some more degreasing. Also need advise for the transition. I’m thinking this will be more decorative than functional, and the vibe I’m going for is “sacrificial dagger”. I think I might torch the bone. Considering a sinew wrap, but not sure. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks good. How much was that? I've been thinking of switching from a touchmark to an electroetcher... It's easy to electromark with just a 9V but deep etching requires DC. Thinking of making a DC converter from an old laptop cord, but don't know if it's worth the time, money, risk etc. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks frosty, but no job offer for me?? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Looking good everyone. Quadstate was a blast, I met up with some guys from the Cincy Blacksmiths' Guild and got an opportunity to do some forging with them. Mine are on the top, my father's (with a bit of help from yours truly) are on the bottom. Was a lot of fun to have the opportunity to do some with my dad. I got a bit overly fancy and tried to do a leaf on my bottle opener. Do not like how that turned out, and additionally I accidentally made it left handed. Will probably cut off the leaf, clean it up a bit, and give it to one of my lefty friends. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

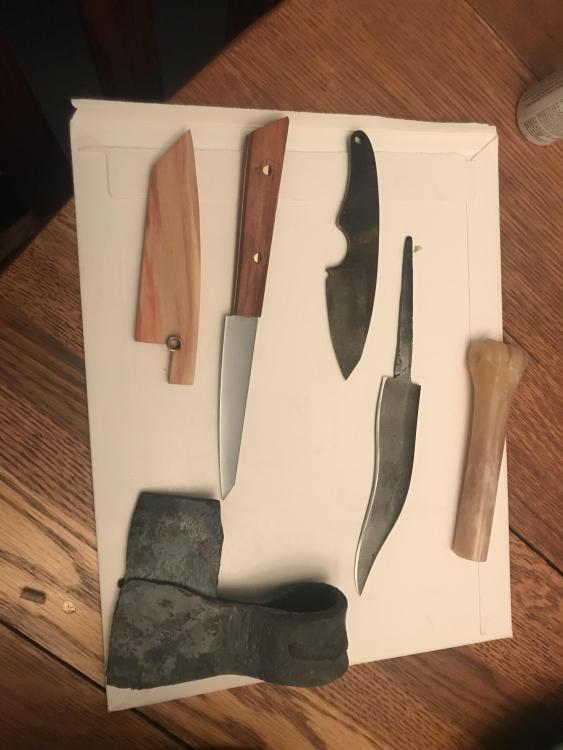

Not sure when that'll happen. I'd like to use that deer radius as part of the handle but it still needs a good cleaning. And also I hate working with bone so might procrastinate on it. Glad the other stuff is looking good, my things have come a long way. Heading there as soon as I finish classes. Hope to see you there. John, I guess that could work. It looks halfway inbetween a persian and a kris. I guess that's what happens when I get bored. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

SOrry to hear that Goods, welds didn't take or something else? Heat treated a pair of neck knives, forged and HT this abomination (kris dagger?), and made this little paring knife as a thank you to someone for some wood. My first time trying a saya, a bit tricky but lots of fun. Can't wait for quadstate after classes tomorrow! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks for the suggestion. I've been trying to keep the eye round throughout the process, but it makes sense that that would make it much harder to get a good weld. Hopefully the next one works out if I can't make this one happen. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Goods and Jennifer, great tomahawks from both of y'all. I'm still on my 4th (5th?) attempt with no luck yet. Praying this one will take, but not too hopeful. It's welded in the middle but not anywhere else. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, love the spoon and fork. I've been trying to make a copper coffee scoop for months, but just can't get a good bowl. Did you use a swage block? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey, that result looks an awful lot like most of my forging when I forget to brush my workpieces!