-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

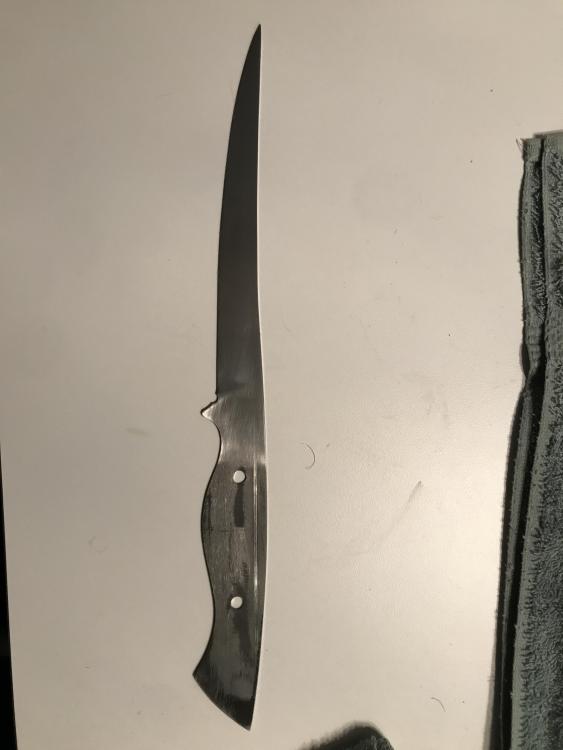

Ah yes, the great black swamp. Messed around with some torch coloring to get this leaf to a nice rainbow color. I think I will give it as a thank you to my chemistry professor. Finished up the blade and started on the walnut handle for this fillet knife that I am giving a friend as a graduation gift (and also in exchange for some welding haha) and made my first kitchen knife, a little 15n20 and purpleheart japanese k tip paring knife. While I quite like it, there are still many things that I'm not satisfied with, so I am already working on another one. My goal is to have made myself a full knife set by the time I graduate (gyuto, petty, paring). In order to do that I will need to start learning some pattern welding or san mai techniques to thicken up my stock. I have finals next week, then I should really be able to hit the forge. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I see. I really need to go to quad state this year. I still have never met up with someone who actually knows what they’re doing, so I’m just spitballing it haha. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy- Is Roy local? I’ve watched many of his videos, and appreciate his no non sense tutorials. I had no idea he was around OH. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I love the axe, Goods. How long does it take you to make something like that? Do you do it all by hand or do you have a press or power hammer? I'd love to make axes, but that seems like a lot of material to move/drift by hand. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks good! I did a bit of leather work as well to make a sheath for this little blacksmith knife I just finished up. It is a neck sheath. -

Gas Smelter and Crucible base

Chimaera replied to BEBailey3's topic in Smelting, Melting, Foundry, and Casting

Hi Bailey. I think the word you are looking for may be "foundry". Melting furnace also works. Smelting is the act of turning ore into a usable product, while melting is just that. To answer your question: most people put a fire brick under the crucible. This helps protect the floor of the foundry, in case you spill or get flux on it. It also provides a level and easily replaceable floor. Finally, it raises it up for better heat circulation. (I'm sorry, I just saw that Latticino covered all those). To make sure your crucible doesn't stick to the firebrick, put a small piece of cardboard between them. It will turn into carbon and keep them from sticking. -

Hi Lucas! Unfortunately, not really. I tried another piece and got completely different results, but still not really what I desired. I have a bit of bar just laying around, so I think I may see if one of the more experienced guys on here would be willing to do some tests for me if I ship a piece to them.

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

The curl or spiral is a blacksmith scroll. While they are beautiful and you create them very well, it is nice to see some of your work that is more sleek. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I love the chairs Alexandr. Very sleek and modern while still retaining the handmade elegance. Finally got back to the forge and tried my new anvil- it’s amazing! The metal moves so much more easily, and it’s actually flat! Started a piece of cable and Made a couple leaves, a little blacksmith neck knife, and a bar of twist mokume. I haven’t done mokume in a while so I seriously misjudged my initial welding temp and ended up with about 1/3 of the original stack. The rest is scattered individual quarters. I need to figure out how to clean and reuse them. This is my first time trying to make a rectangular piece of mokume. It definitely wanted to delaminate. I got it under control, but I ended up with a number of cracks. I don’t know if maybe I didn’t anneal it often enough? Anyway was a fun experiment, and hopefully I can make some necklaces or possibly a ring out of it. I think soon I will build a new mokume clamp and try it in the gas forge (this was in the anthracite forge, which gets hot but is very hard to control). -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Finally got around to handling my flatter with a broken axe handle. Just need to scrape off the lacquer and torch it for a nice charred handle. Now I just need to replace the axe! And the hatchet. And the cross peen. And the ball peens. I’ve got some work to do. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Got some pallet strapping. Tried to do a torch quench, but results were inconclusive. Here is a spark test on an 80 grit belt. Most of the sparks were in the 12-16" range, with some reaching 24". Bright orange to yellow. I know that the definitive test will come when I actually get my forge going one of these days and do a real quench test, but as a preliminary, what do y'all think? IMG-2822.mov -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Oh, didn’t even see the blacksmith knife. Very nice. While I haven’t wet molded a sheath for a blacksmith knife, I have done a few for other styles and can say that it’s by far the easiest way I’ve tried to do sheaths. Just some important hints I’ve figured out- cut your leather oversized, since the clamps leave marks and it shrinks a bit. Spray a bit of WD on the knife and wrap it well with Saran Wrap so it doesn’t rust during the process. Make a few Templates before you get to cutting (I guess that applies to all sheath making). Im the furthest thing from an expert, but they have generally turned out pretty well, and have good fits with wood handles knives. But as I said, I don’t know what it’s like for blacksmith knives. Good luck! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks real nice Goods! I imagine it will end up patinating anyway if it's HC, but that's for the customer to figure out. Les, I like that hawk! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

This is more or less my understanding as well. Makes sense. Thanks for the explanation. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Chad- I have only made a couple (truly horrible) fire steels, but as far as I'm aware they do need to be hardened. If it is too soft, the flint will simply scratch it, instead of chipping off the sparks. At least I think that's why. I've heard that 5160 works well, but someone with more experience would be better suited to answer that. I am looking at teaching a small 1 on 1 class, and I think fire steels may be a good option. First I just need to find some more flint. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Sorry to hear that. Hope you can get it straightened out over the temper. If not, good luck with round two, hope it goes better for you. I'm hoping to do a short sword soon, and I'm really not sure how I plan on doing HT. It's probably good I haven't started on it yet- once I get a project heat treated, I obsess over it. Usually finish it that night instead of taking my time haha. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Chad, those look great! Hope HT goes well! Also, wrench karambit a are a lot of fun, and a good challenge to get the urge right. Goods, that’s a comfy looking handle. The gentleman who recently purchased a fillet knife from me is apparently a prolific prickly pear plant propagator. I know one of the good people on here used to post lots of grafting knives made from bandsaw blade. Does anyone know who that might be? I’d like to talk to them to see their process and what designs worked well for them edit: found them. 671jungle. Unfortunately it looks like they haven’t been on in a while, but I guess we’ll see -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I harden most of my tools, but them being made from a high carbon steel is probably more important. Hardening probably doesn’t matter that much. Cold chisels definitely should be hardened, but make sure the part you hit is soft. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Frazer and Latticino, good work. That's a nice looking hammer. M3F, I like the little hand axe. I've tried making a couple of those with no success. Once I get some thicker mild steel I'll try again. I have precious little WI as it is haha -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I seem to remember it mostly being black, but I’ll test some anyway. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Beautiful work everyone. Alexandr, as always, some of the most wonderful decorative ironwork I’ve seen. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Well, I somewhat accidentally sold a fillet knife. I guess someone likes them! Got started on another. What else can I make with bandsaw blade? I’d like to use it for Damascus, but don’t have the other steel yet. I may test harden some pallet strapping from work, as I’ve heard that can be HC. I want to try little kitchen knives, like small paring and trimming knives. Maybe a bird and trout knife? I have almost unlimited amounts of this stuff for free, but it’s only .042” thick. Next time I light the forge I’ll try to work it down to some thicker stock, but I think it will be a struggle. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Goods, I'm sorry it's not what you expected, but osage orange should also work wonderfully. It's extremely hard, and I like the smell (though that may just be when burning). Padauk is probably one of my favorite woods. It's easy to work, has a lovely smell, and that color can't be beat. Can't wait to see your finished knife! JHCC, I must admit that what you're doing is somewhat outside my league of understanding, but bending 3/8*1 1/2 cold? Wow! Shain, looking good. I need to get myself a twisting wrench like yours. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

A bit of forging, but a lot of stock removal. The bandsaw blade is too thin for me to be able to forge effectively with my level of hammer control. It just wants to crumple instead of thicken. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Here is the second filler knife I made. Bandsaw blade and faceted walnut. Not sure how I feel about the hexagonal cross section. It feels very nice but looks a bit strange.