AngryOnion

Members-

Posts

55 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by AngryOnion

-

Awesome to hear, thank you for the good news.

-

Does anyone work by a dollar amount they want to make? I know it's more typical early on while learning. So instead of focusing on making xx/hr making s-hooks. You figure out you can profit 2$/hook and just take however long to hit your daily goal. Then as you get better you can either raise the daily goal or work less hours.

-

Should I get rid of my old Lincoln welder?

AngryOnion replied to rdennett's topic in Welding Equipment

I would base getting rid of it on your other equipment. Do you have anything made out of 3/8" or bigger that is somewhat likely to break? If I had a tractor with a 3-point hitch I would keep it just for that. -

Checked it out in person today since I was looking at other stuff anyway. Seemed to be in good condition and spun freely. I wasn't paying too much attention when it ended and went for under $50

-

Hi guys a local auction has this massive blower for sale and I was wondering what it would have been used for. The listing says 32"-34" diameter. I haven't had a chance to look in person and probably won't until Monday. Is it worth trying to pick up at all?

-

Exactly what mine got.

-

What did you do in the shop today?

AngryOnion replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, did you happen to have a picture of it? Is it any different than the woodworking ones? -

In Michigan I would expect this to go around 75$. You'll still see them price over $150 but they sit forever until they drop the price.

-

What did you do in the shop today?

AngryOnion replied to Mark Ling's topic in Blacksmithing, General Discussion

Fire poker looks awesome Loafers -

Got a good deal, paid about $120 for the lot. I'll check into what the other stuff is going for as decor.

-

Picked up about 20 pairs of tongs from an auction. The ice tongs and drill bits were with them as well, but I don't know what to do with those yet.

-

Closed on the house yesterday, so here are the pictures of the real thing. Sadly I did not find any other goodies like it doing a quick look.

-

Fair deal or to much?

AngryOnion replied to Dave Murray's topic in Blacksmithing, General Discussion

Prices seem in line to me for it being Canadian Dollars. -

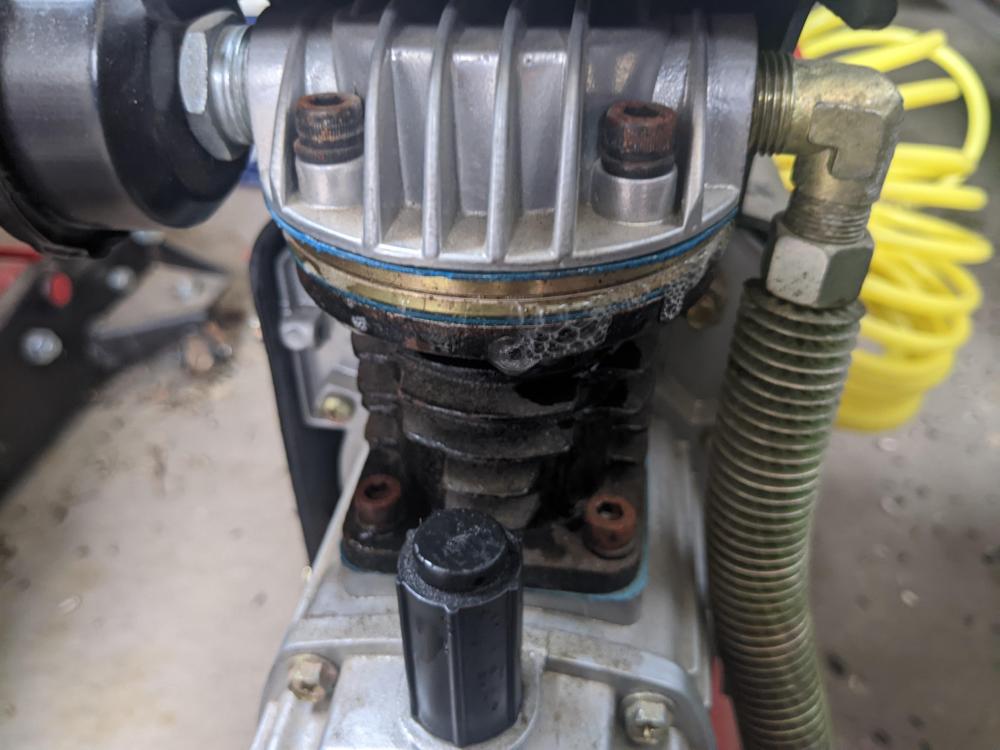

Replaced both gaskets for cylinder head and good as new now.

-

-

So this just happened after I made this topic. My small 3 gallon air compressor started leaking. I put soapy water and it is leaking between the two brass pieces. Is there a gasket that needs replaced? It is a Craftsman 3 gallon direct drive. I'm busy most of today but might be able to take it apart tonight.

-

Hey guys, what are your opinions about buying good sized (50+ gallon) used air compressors? I'm worried about the hazard of not knowing how well they were taken care of. Is there an age cutoff you do or what else do you look out for? I know they can last for decades but I'd rather be safe than sorry.

-

I had a similar instance once, although I didn't even get talked to about it. Our shop was retrofitting amphibious personal carriers for the USMC. Everything had to be welded in flat or horizontal, so the vehicles needed to picked up with 2 overhead cranes inside and rotated. I don't remember the exact weight but I think it was near 10 tons. I had it up in the air and halfway flipped and this genius I worked with just starts walking right next to it. I stop, yell for him to move. He looks up, asks what the big deal is. Tell him much less nicely again and he moves a step or two back. Now I'm seriously annoyed, telling him to go anywhere but here. Eventually he does. Was typically a quieter guy and never tried to report me. Find out later he is struggling bad with alcohol and his marriage and he wasn't even old enough to drink. Got caught drunk on the job (5am) a couple times and fired. He might not care about his life but I did.

-

We are planning on splitting the property with my wife's parents and he has done quite a bit of chainsawing, but really isn't safe. He would have made a great botanist, but probably a dead arborist. Just yesterday he brought over something to for me to weld and kept walking my spark path while I was grinding bevels on it. Just has no idea how much damage a 1/2# piece of steel can do if I let the belt grinder throw it.

-

Wasn't trying to make excuses. Just saying I'm inexperienced. I've only used a chainsaw about 10-15 hours lifetime so far, but that will change quickly with the new place. Still about a month until we own it and they move out, so will be a while before I find any other goodies.

-

Well thank you guys for the information. I'm very much a novice since my dad never took the time to teach me.

-

I was helping out my father-in-law clear downed trees the other day and noticed one of his chainsaws had a trigger lock. Seems like an incredibly bad idea to me but I don't use them a whole lot.

-

Have not tested it yet, in process of buying the house and older lady owner specifically has in contract she is not cleaning out the barn.

-

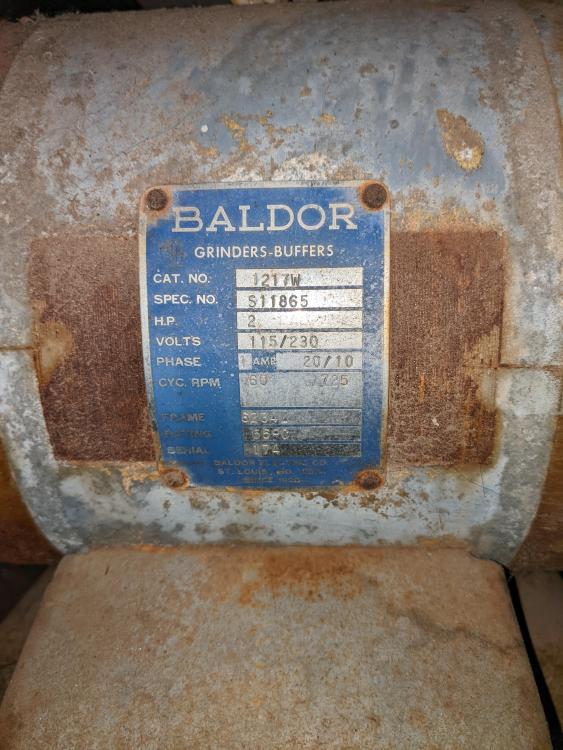

Hi guys, I am in the process of purchasing a new house and in the barn there is a massive bench grinder (Baldor 1217w, 2hp, single phase, 115/230, 12"x2" wheels.) It is not mounted on the pedestal so I would assume it is gone. Picture is just for reference, not this exact one. I don't have any real use for it as of right now, and was wondering what a fair selling price would be? I see a new model is 4-6k. Thanks.

-

Good movie, but I think that's a one timer for me. At least until the kids are old enough to enjoy it.