d72hemi

Members-

Posts

6 -

Joined

-

Last visited

-

Jackhammer for forging?

d72hemi replied to Austin Ferraiuolo's topic in Power Hammers, Treadle Hammers, Olivers

Purple Bullet, That is a cool set up. Do you get much impact/vibration sent back to your foot raising the anvil to the jackhammer? -

That is just my resent find. The weight restrictions for an E-6 is 11,000 lbs, and I am a bit over that. My other blacksmithing items that I picked up over the years are a coal field forge (pictured just behind the anvil) 2 German post vises(40/50 kg), 1 French post vise (kg), my first anvil (80kg, WW2 German army) plus BLO'd oak stump, looks like a nice furniture piece, and many tongs and hammers. If this was an antique furniture forum I would have even more to post! Blacksmithing equipment is about 10-20 cents on the dollar out here, but if you have to pay for shipping that is the deal breaker. A couple day before the movers came my wife told me that she wants/needs to buy 400-600 Euro of clothes before we go, I told her "only if I can buy the equivalent in tools". She agreed, not knowing that I was watching that anvil for a few days trying to think of a way to get her to buy off, and not be upset with. Since my flight out of here is delayed 24 hours I will try to find time to post pictures of the above listed equipment that is following me home to the US.

-

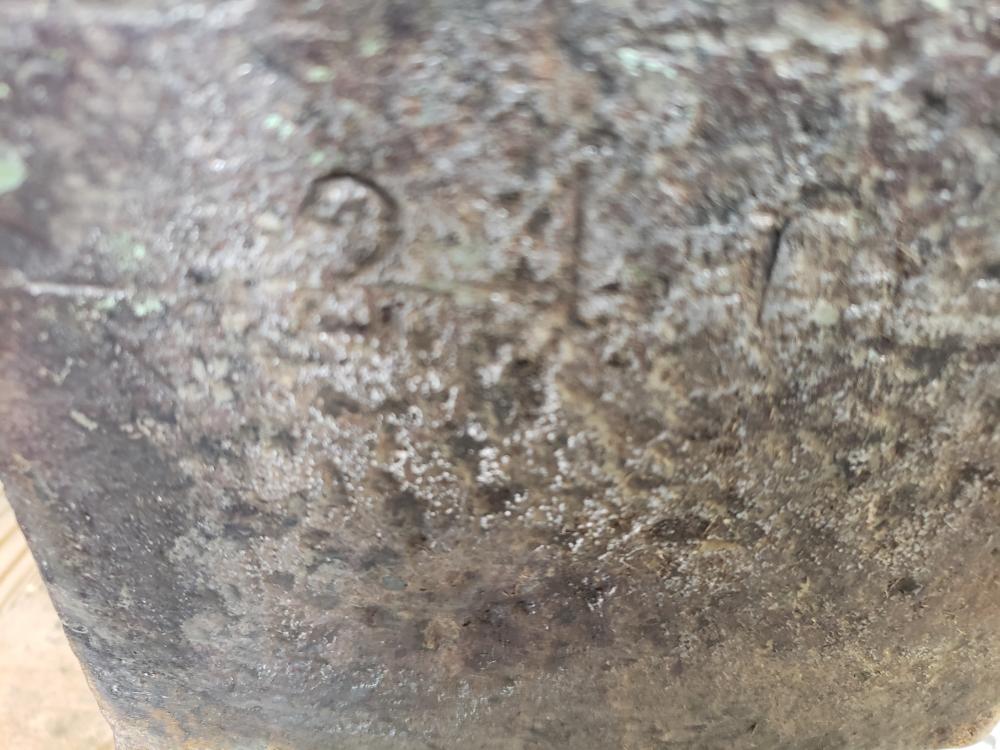

A 210 kg (463 lbs) S&H from 1940 followed me home in two ways. I found it for 400 Euro ($470) just days befor the movers packed my house. After 10 years of being stationed in Europe my family is heading back to the US. I masked the face but gave the sides a quick and light coating of spray paint since movers can complain about rusty objects.

-

ThomasPowers, Please correct me if my thought process is incorrect. Assuming that the fire is properly maintained, the ideal location to heat steel is about 4 inches above the bottom of the fire pot, with a few inches of coal covering it. Since the fence top is 4 inches above the bottom of the firepot, this should make it so the steel to be heated should be able to rest on the fence while parallel to the ground. Am I missing anything? Also, do you see any advantage in using the bricks to "extend" the firepot as in the first set of pictures?

-

OK, I took and modified the advice. I built a fence to the hight of 4 inches above the bottom of the firepot. I then built a ducks nest, also to a hight of 4 inches above the bottom of the firepot. Unfortunately, the skills I mastered while making hidious, asymmetrical crap out of clay in school a few decades ago did not transfer to the duck's nest. I fired it in place by burning firewood over it. I should have baked it in the oven on low to ensure all of the moisture was driven out before firing at high heat, that would have prevented it from exploding into a thousand pieces. I think I will just try it with the fence, keeping the outer coal wet. At least this will help keep the coal from falling off of the edge. I believe this setup is similar to Roy's forge (Youtube channel Christ Centered Ironworks, https://www.youtube.com/watch?v=xXwqMpSYsCI), but I have an electric blower. Hopefully during my leave the next two weeks of leave the weather will allow me to try some forge work done. I will keep you all posted, Thanks for all the information you have provided me.

-

Yesterday I fired up my first forge for the 3rd time yesterday, each time using bituminous coal. I know the firepot is shallow, and maybe a too large in width and length (Depth 1.5", base 8"x6", top/opening 11.5"x10") so I am looking for recommendations to remedy my forge situation. My first attempt was to pile coal and try to keep steel at least 5 inches from the bottom of the firepot; I burnt nearly everything because I let nearly everything get to low (2-3 inches from the bottom). For my second attempt, I made a wire frame above the firepot as a visual marker to keet the steel ar or above 5" and thereby outside of the oxidization area. Yesterday I put a parameter of bricks around the firepot, effectively raising walls to 5 inches. This worked much better, so the only times I burnt anything was when I failed to recognize a large clinker had formed. I do think that the brick solution increases the effective size of the firepot to much, and it limits cokeing of the coal outside of the firepot and maks it difficult to pull in new coal/coke into the firepot. I think the best solution, besides buying a new firepot, is to build a clay duck's nest that reduces the volume and has an external ramp for feeding new coal/coke into the fire pot. Please let me know if my idea is good, or if you recommend another route.