-

Posts

296 -

Joined

-

Last visited

Contact Methods

-

MSN

enoch@warrior-way.org

-

Website URL

www.warrior-way.org

Profile Information

-

Gender

Male

-

Location

Box Elder, SD

-

Interests

Shooting /reloading, fabricating /welding, leather work, forging

Recent Profile Visitors

1,865 profile views

-

What did you do in the shop today?

Cannon Cocker replied to Mark Ling's topic in Blacksmithing, General Discussion

That is a beautiful knife jobtiel -

What did you do in the shop today?

Cannon Cocker replied to Mark Ling's topic in Blacksmithing, General Discussion

The thumbnail I saw was off a processor so I copied the link without watching the whole video. Sorry for my laziness!!! Here a picture of one. -

What did you do in the shop today?

Cannon Cocker replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy the base is a drive wheel for a log processor. It’s what pushes the logs through the limbing blades and sets it to the length before it’s bucked. this video shows that at Work. -

What did you do in the shop today?

Cannon Cocker replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Cannon Cocker replied to Mark Ling's topic in Blacksmithing, General Discussion

I am afraid of making it too cluttered, and considered not doing one side of the table. But I figure it’s much easier to remove than add on. The base is a drive wheel for a log processor and they weigh about 80 lbs so I can put a decent amount of pressure on things. If it does start to twist or get tippy it’s easily handled with one foot on the base. I have my other leg vise similarly mounted. -

What did you do in the shop today?

Cannon Cocker replied to Mark Ling's topic in Blacksmithing, General Discussion

I got my new vise mounted and adjusted (the jaws were over a half inch out of alignment). I intended to put a 2” fence around the table, but now I’m debating mounting a small bench vise and a pipe vise on it. I also am thinking about adding two inches to the width of the jaws on the leg vise. It’s as heavy as most 6” vises I’ve seen but only has 4” jaws. -

Yep it worked out pretty well. He got the vise cheap and fixed it up. When you figure the time and money we both had invested it was pretty fair. Plus I’ve got a lot of HC steel and rail road spikes that I’m sending his way as well.

-

I met a young man who is starting in our addiction who has a post vise that he has restored and wanted to sell. I talked him into trading for a hammer. He decided the “hammer” he wanted was a flatter. I didn’t take the time to tell him that they aren’t in the same category and made him a flatter. I just picked up the vise today.

-

I think the lathe beats the wire wheel because although a wire wheel can hurt you bad it can't suck you in one side and spit you it the other looking like an empty tube of toothpaste! For now I'll get one of those lockable plug covers to keep the kids from doing an imitation of used dental supplies. I won't be using this enough to need the fancy quick change tool holder. Plus I think I'll enjoy shaping my own cutters. I like to do as much on my own as possible for my projects. Unless my income depends on it. Then I'm all about saving time!

-

I have always believed that the lathe is THE most dangerous shop tool out there. I'm always conscious of the fast spinny parts because of how fast they can grab you and ruin your life. So after bringing it home I had a very serious talk with the kids explaining the dangers of the machine and telling them under no uncertain terms they were to never touch it unless I told them they could. Then I showed them a (very mild) video of a guy getting wrapped up in a lathe to drive the point home. I also want to put a lock out on it so they can't adventure when no one is watching.

-

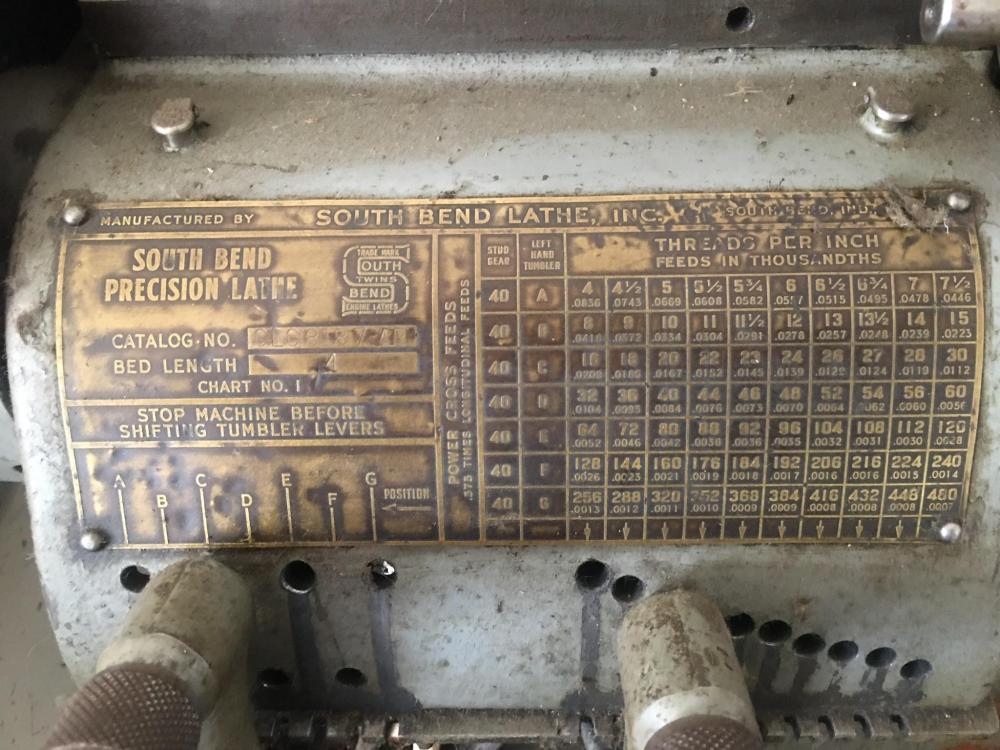

Thanks for the advice Frosty. I'm not new to machining (far from coinciding myself a good machinist) I worked for two years as a machinist making suppressors on CNC machines, then another 2.5 years as a millwright running manual lathes and mills. Where my knowledge lacks is in the tooling itself. All of my experience is with carbide insert tools, so the different shaped cutters and bars and old style tool holders are what I need to get figured out. Not hard, it's just gonna take time to learn how to use sharpen/shape them.

-

I have the original, just need to read through it and play with the tools as I do to get my mind wrapped around it.

-

Thanks TW I've got quite the task ahead of me. This is a few generations of tooling ahead of what I'm used to so I've gotta read up and figure out what does what!

-

Today is a really exciting "it followed me home". I keep being blessed with being trusted as the custodian for good family heirlooms. I brought home my father-in-law's 10" South Bend lathe complete with all of his tooling and a bunch of stock. He was really particular about maintaining his tools so this thing is in amazing shape. Now it's my job to keep it that way for the next generation!

-

What did you do in the shop today?

Cannon Cocker replied to Mark Ling's topic in Blacksmithing, General Discussion

Love the wand, gas keys, and especially that candle holder!