-

Posts

3,994 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by George N. M.

-

Concrete clinker for the shop floor?

George N. M. replied to Candidquality's topic in Building, Designing a Shop

In soil science the name of the soil, in this case, Crockett, is the name of the location where it was first described scientifically. It is the same as with geologic formations, e.g. the Mesa Verde Sandstone, the Oglalla Formation, or what I am sitting on and get my well water from, the Casper Formation. So, this soil type was first described near someplace named Crockett (not surprising in Texas). The soil type will vary geographically. Hence, in your area it is fine sandy loam. A mile down the road it may be somewhat different, maybe coarse sandy loam. GNM PS I just mentioned this to my wife, Madelynn, and she raised the issue that if the clinker breaks down under use and becomes dusty that the dust may pose an inhalation hazard. This might not be a problem if it solidifies when moisture is added but it is probably an issue that needs to be addressed. I'm less concerned about this material because it is made of carbonates than I would be with something like coal clinker which is mostly silicates which break up into very sharp particles which can result in silicosis ("miner's tuberulosis"). G -

Show me your blacksmith pets

George N. M. replied to Glenn's topic in Blacksmithing, General Discussion

I agree with Frosty. Buster looks like he is "snoopervising" to make sure that you do it right. Here is a link to a photo of a scout dog and his handler that worked with us in Viet Nam, early 1971. https://www.charliecompanyvietnam.com/class_gallery.cfm?gallery_id=26406&member_id=5514692 In this gallery are photos I took in the bush in Viet Nam 1970-71. I was Platoon Leader of 1st plt, C 1/12 Cav, 1 Cav Div (airmobile). G -

Concrete clinker for the shop floor?

George N. M. replied to Candidquality's topic in Building, Designing a Shop

I'm aware that your climate is a LOT different than semi-arid Wyoming (Laramie gets about 11.53" in precipitation/year) because I have two brothers-in-law near Tyler, TX. You might check with your local US Department of Agriculture office and look at the soil maps of your area and then look at the characteristics of that soil type. Also, the local office of the Texas Department of Highways (or whatever the actual Texas title is) may have engineering data on your particular soil type. A phone call to the local highway engineer may give you a lot of information about whether cement clinker is a good or bad idea. Keep us informed about how it all goes. I'm finding this interesting. GNM -

Concrete clinker for the shop floor?

George N. M. replied to Candidquality's topic in Building, Designing a Shop

It sounds like you have soil with a heavy clay component and that where is a fair amount of expansion and shrinking depending on whether conditions are wet or dry. Have there been any issues with shifting or cracking foundations in your area? (I suspect not because that is usually the result of very expansive bentonite clay which is altered volcanic ash. That is more common in the Rocky Mountain area than in Texas.) I believe that means that you wouold need a thicker layer of anything, gravel, cement clinker, etc. to support a load than you would if you had sandy soil which is more solid and compacted when wet. If it were me, I'd get the equivalent of a couple wheel barrow loads and lay out a few small test areas of a couple square feet each and then use different variables, depth, intentionally soaked, dry, etc. and see what happens. I'd drive one tire of a vehicle across them to observe load bearing characteristics. This is, of course, if you can't find anyone with experience with cement clinker which would give you more guidance as to its suitability than experimentation. I still think that a call to the marketing department of the company manufacturing it would be worthwhile. "By hammer and hand all arts do stand." -

Very nice work, particularly for a first outing. I like the pattern welded steel a lot. The only thing that I would change is the star drive screws but that may just be my personal preference. I think brass rivets would give a cleaner look. Back when I was a criminal prosecutor I had an interesting discussion with a police officer who wanted to charge someone with carrying a dangerous weapon. IIRC, the local ordinance was 3" and the knife in question was very close to that. It was slightly over when measured from the tip to the handle but less when the edge was measured. I refused to bring the charge because I felt that it was ambigous whether the "blade" should include the unsharpened portion. And I personally thought that the ordinance was kind of dumb anyway but I didn't say anything about that. The officer was just trying to stack charges IMO. I agree with Frosty about the background in the photos being too busy. "By hammer and hand all arts do stand."

-

Welcome aboard from 7500' in SE Wyoming. Glad to have you. If you put your general loction in your profile we will be able to give better answers to your queries. A surprising number of issues are controlled by geography. Also, we may be able to suggest local blacksmithing groups and you may be within visiting distance of other smiths. There is nothing better than learning from someone with more experience. I was a lone eagle for the first dozen or 15 years of smithing. It was pre-internet and all I had for instruction were books from the library and my own mistakes. This is a world wide forum and we don't know if you are in Lapland, Tasmania, or Kansas. Re your hammer: Yes, it is obviously a first try but it will work. You ought to be able to compensate for the irregular eye by some custom work on a handle blank. You may need to start with a plain chunk of wood (hickory is a good material but other hardwoods will work) to come up with a shape that will fit the eye. The one thing that bothers me a bit is that in the last picture the head does not appear to be at 90 degrees to the handle. This will likely result in the hammer head hitting your hot metal crooked and that is not a good thing. You may need to drive a wedge in the front of the eye from the bottom to rotate the head a bit. "By hammer and hand all arts do stand."

-

Show me your blacksmith pets

George N. M. replied to Glenn's topic in Blacksmithing, General Discussion

So sorry to hear this. It is our curse to outlive our friends and families, both human and furry. But I am convinced that they will be there on the other side of the Rainbow Bridge. Expect Buster to be there waiting for you and asking what took you so long and did you bring treats. Sadly, George -

Concrete clinker for the shop floor?

George N. M. replied to Candidquality's topic in Building, Designing a Shop

You may want to get a small amount (say, a few hundred pounds) lay it out and experiment with how it acts on its own or mixed with gyp. G -

Concrete clinker for the shop floor?

George N. M. replied to Candidquality's topic in Building, Designing a Shop

I would think that it would perform like gravel made of softer rock in that IIRC cement clinker is fairly soft, softer than, say, limestone rock. So, under heavy weight, e.g. a driveway, the individual chunks would break up into smaller pieces and would compact more. Also, it appears that cement clinker is reactive with water and will become harder if exposed to moisture. So, if you are using it outside exposure to rain would give you something more like limestone gravel. Inside, it would probably harden eventually but would take longer. I'm not sure if I would like a gravel or gravel like floor in my shop. I think it would be less comfortable than dirt or concrete to stand and walk on. How much thickness you need is more an engineering question and dependent on what kind of soil you have and what kind of uses you contemplate. For a shop floor where it only has you walking around on it I would guess that you wouldn't need more than a couple of inches. Compacting is always good. If you have a choice, I would get the finest size available and then wet it down to harden. If you can get a crusher I'd think that pea size and smaller would give a flatter and more solid floor. It may be that if you are using a vibrating compactor it will break up the chunks and give you smaller size particles. I have seen power plant fly ash which I believe is similar to cement clinker used as sort of a poor man's concrete for dust suppresion on dirt roads. It is put down dry and then a water truck sprays it down. As to whether you need to dig out an area or just put it on top of the existing soil would be, IMO, a question of whether you have power excavating equipment available. Digging out even 4-6" of dirt by hand is a very demanding project. I've thought about having a concrete floor laid in my shop which is a dirt floored old horse barn and the only way I'd think about doing it is if I could hire a crew to dig out the dirt to the depth I'd need. I'd ask around with local contractors, particularly those who do driveways, etc. and see if they have any experience with it and what their experience has been. If there is a cement plant in your area you might call their marketing department and ask about uses for cement clinker. Just to be a bit pedantic I am using the term "cement clinker" because it is an intermediate step in the production of cement which is added to sand and gravel to make concrete. Good luck and let us know what you decide and if you go with it how it works out. GNM -

Voldemar, That is a very good price by American standards. Here, it probably would have been $US 4-6/ pound ($US 8-12/kg). From what our European members have said it seems that anvils are more plentiful and cheaper and post vises are rarer and more expensive on your side of the ocean than they are here. We'd love to see some photos of your work. "By hammer and hand all arts do stand."

-

Oh, that is a lovely anvil! Of you don't mind my asking, how much did you have to pay for it? I have no idea how much anvilos sell for in your part of the world. By the way, nice shop. "By hammer and hand all arts do stand."

-

Gondowanaland was a big place and not many folk around. G

-

My son, who was raised by two geologists, insisted that his mother and I had been born in the early Cambrian. GNM

-

You'd think we'd get lots of rattlers around here but in reality you don't get many snakes above about 7,000' in elevation. I've seen a few garter and other non-poisonous snakes around Laramie and in the mountains but I've never seen a rattlesnake this high. Too cold in the winters. However, there are parts of the state that can get pretty snakey and you have to watch your step in places. The snake populations tend to fluctuate along with the populations of small mammals. Generally, if I get buzzed at I will just back off and go around. However, it can still give me a pretty good jolt of adrenaline. GNM

-

Carboniferous oxygen levels are estimated to be about 35% versus 21% today. This allowed terrestrial arthropods (insects, millipedes, spiders, scorpions, etc.) to grow much larger than they do today. Dragonflys had a wingspan of 2.5 feet, millipedes were 8' long and 1.5' wide, and scorpions were about the size of a house cat. Here is a link to an article on Carboniferous creepy crawlies: https://owlcation.com/stem/The-Carboniferous-Period-When-Giant-Insects-Ruled-the-Land-and-Sky GNM

-

The need for Atomic Annie passed when nuclear warheads were miniaturized enough that they could fit in regular field artillery weapons, e.g. 155mm. One of my more arcane areas of knowledge and training is that I am a certified Nuclear and Chemical Targeting Officer. One of those areas of which I am VERY glad I never had to use except in exercises. I've climbed around on Anzio Annie and the USN railway guns and walked around Atomic Annies at Ft. Sill, OK and the Nuclear Energy Museum in Albuquerque. GNM

-

That monster would probably have never been built or deployed because there wasn't a bridge in Europe that could have supported it. Probably more a fantasy concept to impress Der Fuehrer as a wonder weapon than anything that had any real or potential combat effectiveness. There are two preserved railway guns in the US that I know of. One is a German K5(E) ("Anzio Annie") which is at Ft. Gregg-Adams, VA (formerly Ft. Lee). The other is a US Navy 14" railway gun used in WW1 at the Washington Naval Yard Museum. There are also a number (7) surviving M65 11" guns ("Atomic Annie") around the US. They are similar in size to railway guns but had large truck type prime movers. Railway guns had their most effective moment in WW1 when the front was static and firing positions could be built behind your lines and there was a thick net of railroad lines to deploy them. All the major combatants fielded them. Since large caliber guns are slow to make the US pulled quite a number of large coast defense guns out of forts in the US, mounted them on RR carriages, and sent them to France. After WW1 many of the RR guns were used as coast defense weapons in the US, Panama, and Hawaii. GNM

-

The tale is an American version of the "Musicians of Bremen", a German folk tale collected and published by the Brothers Grimm is 1819. Versions go back to the Middle Ages. Here is a link to the Wiki article: https://en.wikipedia.org/wiki/Town_Musicians_of_Bremen GNM

-

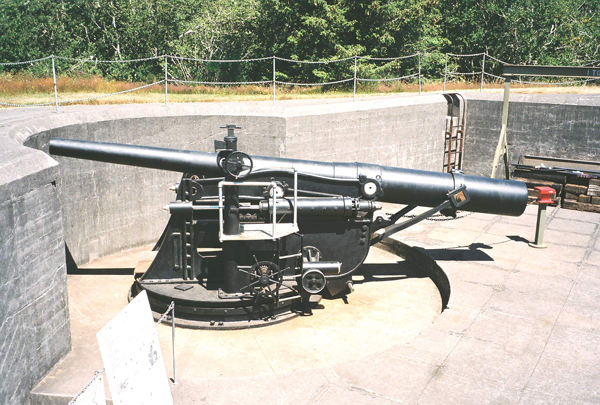

Speaking of historic reproduction artillery here is a reproduction 6" gun on a disappearing carriage at Ft. Stevens, OR aaaaa0mouth of the Columbia River). These were coast defense weapons which were active from the 1890s to WW2. They were loaded in the retracted position, as shown, and then when ready for firing a big counter weight in a well was tripped and the barrel would rise over the parapet for firing. The recoil would bring it back into loading position. On this carriage (15 degrees maximum elevation) this gun could shoot a shell weighing about 100 pounds up to 17,600 yards (10 miles). I've worked with a surviving one in San Francisco and it is a LOT of work to turn the big crank to raise the lead counter weight. But it is very cool to trip it and see the gun rise into the firing position.

-

Probably a very good score. Snowplow blades probably are a more complex alloy than plain 1090 because of the need for abrasion resistance. This may make it somewhat harder to work. My suggestion is to cut a 1/4" or so off the end and experiment with how it works and how it heat treats (and keep notes). Try different quenching mediums and break pieces off so that you can examine the grain structure. If it works out you have gotten a piece of high C steel that you will be using for years at less than scrap value. "By hammer and hand all arts do stand."

-

in a situation like this where you are making things for a specific audience at a specific location you have to be aware that you may, and probably will, saturate the market pretty quickly. We make durable goods and once a person has bought an X they are unlikely to buy a second one. I have done events where I did great the 1st year, OK the 2d year, and barely covered costs the 3d year because the same people were coming back every year and they had already bought the things they wanted from my offerings. So, you either have to keep coming up with new items to attract subsequent sales or move your stuff around to different outlets where a new group of customers will be exposed to your wares. "By hammer and hand all arts do stand."

-

This is yet another time that I miss Thomas' input since he had a medieval falconette which IIRC was about golf ball caliber. G

-

Also, you will often see folk ramming with one hand. You really don't need the force of both hands to firmly place the projectile against the powder charge. BTW, there are a number of internet sites about how to build a cannonball mortar (no links intentionally). Apparently there is a specific size of compressed gas tank that is used in welding shops that is just the right size and is, of course, good quality steel and stessed for the pressure involved. G

-

The touch hole is sealed with a thumb to keep air from blowing out of it during ramming to avoid fanning any sparks in the bore. There is a thing called a "thumb stall" which is a leather pad to protect the thumb from the heat of the gun tube. There is also a safety rammer which has a cone shaped head so that it puches the hands out of the way incase there is an accidental discharge and the rammer staff comes flying out of the barrel. There are re enactment groups that require the person ramming to wear heavy welders gloves while ramming as a safety thing. There is a big Scottish-Irish festival in Estes Park, CO that I used to demo at (until they started charging crazy booth fees). There was always a group there with period weapons including a bowling ball mortar. They made it out of large piece of pipe with a smaller, heavier, detachable chamber welded to the base. They would fill the chamber with a few ounces of black powder (maybe 1/2 cup) and screw it to the breech where a bowling ball had been loaded. When fired it would launch the bowling ball about 300 yards into Lake Estes. They once hit a rock and the bowling ball bounced about 50' into the air and about 100 yards further. Luckily it landed in the water. If it had bounced in another direction it could have hit folk on the shore. Moral of the story: sometimes you do hit your aiming point and you need to consider what will happen if you do. IIRC after that incident they used an inflatable dragon anchored away from the rock as an aiming point. The lake is a reservoir and is drawn down in the winter and they'd go out when the water was down and collect the bowling balls for future use. I don't think that it would be too difficult to constuct a bowling ball mortar if you were a decent welder. It would be safer than a long gun because the powder charges are much smaller and the pressures are much lower. You'd just have to find the right diameter pipe (bowling balls are 8.59" in diameter) and a breech piece (IIRC it looked like the hemispherical end of a pressure vessel welded to the pipe/barrel. GNM One of my pet peeves in historical movies is when the cannons don't recoil. Oddly, you will see cannons recoiling much more often in naval movies, e.g. Master and Commander, than you do in movies set on land. As can be seen in the video muzzle loading cannon recoild back 5-6' pretty violently and you do NOT want to be in the way. G

-

Being an old artilleryman this is something I have always wanted to get into but never have for various reasons. If you haven't watched this Youtube video it will show how full size Civil War cannon recoil when fired with full charges and projectiles: