-

Posts

24 -

Joined

-

Last visited

-

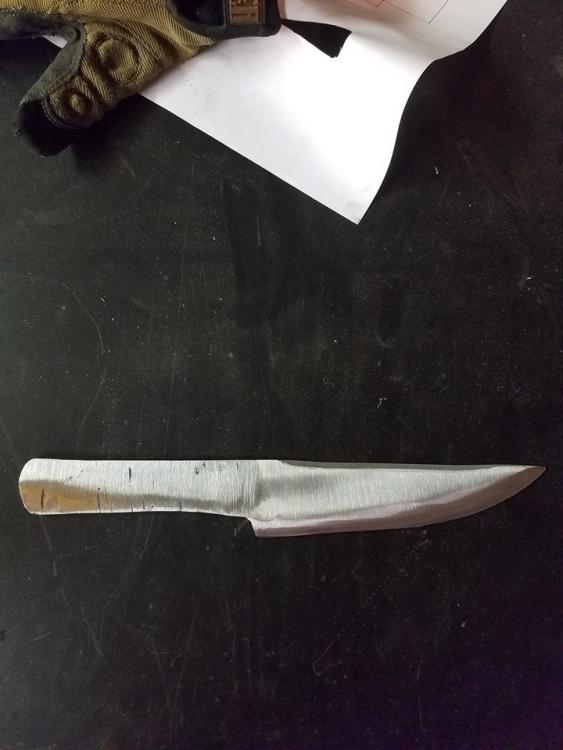

I finished it and took all of the suggestions that were posted here and they helped a lot! Far from perfect but I learned a lot from the process. A lot of do's and more DON'T DOs. This pic isn't the absolute finished product. I cleaned the blade and handle up and finshed the edge. I need to work on my bevels a lot more but forging them in is probably the best step rather than grinding. I need to dial in my hammering skills and take my time but that will come. I used a 1x30 belt grinder which was mind numbing and not efficient at all. I purchased the plans for the No Weld Grinder and Sander Plans from Midwest Knifemakers Supply and will be buying and gathering the components needed over the next month or so. I am looking forward to getting this thing built and put to use.

-

Thanks, Buzzkill and MastaStan.

-

Thanks, everyone. that's a lot more responses than I expected. I will do the heat treat this weekend and post how it went. Another question I have is: should I heat the oil up prior to the quench? I've read that some people don't and others say to do it. I'm not exactly sure which is the best route to take here.

-

Ok, that makes perfect sense, Will. I certainly understand the reasoning for the blade portion but I wasn't clear on the tang. I REALLY appreciate the feedback!

-

Thanks, Stan. Will, so it's better to not harden the tang? I want to make sure I get this right so I appreciate your insight.

-

Thanks, Buzzkill. I really appreciate the suggestion and I will do that. Seeing as it's my first attempt I probably won't stress myself out with making a guard on this.

-

Good catch! That was the plan as well but I failed to put that in the post.

-

Here is my first attempt at a forged blade. The piece i used to start with was 6.5 inches of 1084 steel. I drew it out to 11.5 inches and shaped it. The grind isn't finished yet as I have to bevel it out and finish forming the grip on the tang. I will take care of that this coming weekend and heat treat it. I learned a LOT from the forging process as far as hammering is concerned. Grinding is harder than I expected but i'm using a 1x30 belt grinder so it's taking a long time. Any and all suggestions are welcome if you have any!

-

That is a beast! Even dropping it on a foot will do some damage.

-

Good looking blade!

-

Nope, no powerhammer. NO idea what the stainless is either. nothing identifying marks on it.

-

Nice Craigslist Mousehole just popped up

Hawk200 replied to Lou L's topic in Anvils, Swage Blocks, and Mandrels

I'm tempted to contact him about it. -

I just scored a rod of stainless steel from a buddy of mine. Weighs about 30lbs. I'm not too familiar with stainless steel but I may try to mess around with it this coming weekend. I stil haven't finished my anvil stand yet.

-

What! You hit the jackpot for steel! Too bad it didn't work out for the anvils. 4 of them and not one available. Hopefully he will part with one eventually.

-

wow....I didn't realize that was the size!