-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Hawk200

-

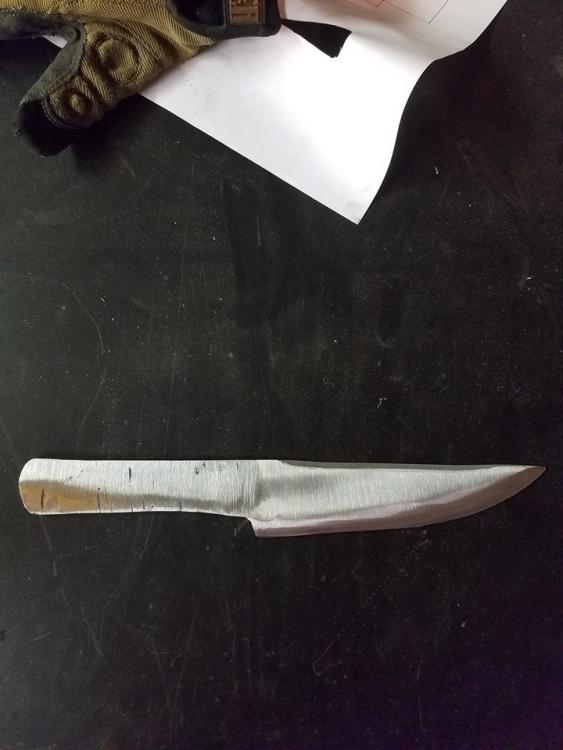

I finished it and took all of the suggestions that were posted here and they helped a lot! Far from perfect but I learned a lot from the process. A lot of do's and more DON'T DOs. This pic isn't the absolute finished product. I cleaned the blade and handle up and finshed the edge. I need to work on my bevels a lot more but forging them in is probably the best step rather than grinding. I need to dial in my hammering skills and take my time but that will come. I used a 1x30 belt grinder which was mind numbing and not efficient at all. I purchased the plans for the No Weld Grinder and Sander Plans from Midwest Knifemakers Supply and will be buying and gathering the components needed over the next month or so. I am looking forward to getting this thing built and put to use.

-

Thanks, Buzzkill and MastaStan.

-

Thanks, everyone. that's a lot more responses than I expected. I will do the heat treat this weekend and post how it went. Another question I have is: should I heat the oil up prior to the quench? I've read that some people don't and others say to do it. I'm not exactly sure which is the best route to take here.

-

Ok, that makes perfect sense, Will. I certainly understand the reasoning for the blade portion but I wasn't clear on the tang. I REALLY appreciate the feedback!

-

Thanks, Stan. Will, so it's better to not harden the tang? I want to make sure I get this right so I appreciate your insight.

-

Thanks, Buzzkill. I really appreciate the suggestion and I will do that. Seeing as it's my first attempt I probably won't stress myself out with making a guard on this.

-

Good catch! That was the plan as well but I failed to put that in the post.

-

Here is my first attempt at a forged blade. The piece i used to start with was 6.5 inches of 1084 steel. I drew it out to 11.5 inches and shaped it. The grind isn't finished yet as I have to bevel it out and finish forming the grip on the tang. I will take care of that this coming weekend and heat treat it. I learned a LOT from the forging process as far as hammering is concerned. Grinding is harder than I expected but i'm using a 1x30 belt grinder so it's taking a long time. Any and all suggestions are welcome if you have any!

-

That is a beast! Even dropping it on a foot will do some damage.

-

Good looking blade!

-

Nope, no powerhammer. NO idea what the stainless is either. nothing identifying marks on it.

-

Nice Craigslist Mousehole just popped up

Hawk200 replied to Lou L's topic in Anvils, Swage Blocks, and Mandrels

I'm tempted to contact him about it. -

I just scored a rod of stainless steel from a buddy of mine. Weighs about 30lbs. I'm not too familiar with stainless steel but I may try to mess around with it this coming weekend. I stil haven't finished my anvil stand yet.

-

What! You hit the jackpot for steel! Too bad it didn't work out for the anvils. 4 of them and not one available. Hopefully he will part with one eventually.

-

wow....I didn't realize that was the size!

-

haha, sounds like you are all set for scrap. Jeez! that's nice.

-

Haha, I have two children as well. 7 year old son and a 5 year old daughter so I know how it goes. have fun on your trip. Hit me up after you get back and we can set up a Saturday and crank the forge up.

-

Even more reason to go talk to my local mechanic! Lou, that would be great! having someone with a bit of experience show me a couple of things would be fantastic.

-

Ah, very good to know. I have a mechanic in my town that I can check with. Most likely the coil springs will be used but at least it will be something to practice with if I can get my hands on them.

-

I actually don't work at UConn but I have an acquaintance that does. JHCC, I just bookmarked the web site for Logan Steel. I will be making a trip there soon!

-

Thanks, Lou! I actually saw your profile after I joined. I was looking for people in the CT area that's on this forum. So, you're right. I am using the rebar to figure out hammering and shaping without wasting time and money on good steel. That's exactly why I was looking for spikes so I can figure out movement with thicker stock. HAHA, grinding was mind numbing to say the least. So far the gas forge seems to be working great but i've only used it a couple of times and I don't know exactly what to look for yet. I appreciate you mentioning it. And, THANKS! I haven't even looked around for places to buy handle materials yet.

-

Exactly! I've been on other forums that I've been a moderator on (for bodybuilding) and that was an unwritten rule as well. So I take that to any other forum I go to. So far the search engine on the site has provided the content I've been looking for but I will keep that in mind if I have a problem looking for something.

-

Thanks, JHCC. I updated my location and profile as suggested. Thanks for the tips!

-

Hi everyone! I just happened to come by this place by doing a search on railroad spikes....first link to pop up! I'm glad I found it. I just read a few topics and I am as giddy as an 8 year old girl with a xxxxxxx puppy! Anyway, I just started this craft about two weeks ago. I have a slight addiction to Forged in Fire and watching Alec Steele on youtube. Of course there are others I have been watching too. I purchased a Majestic 3 Burner Knifemaker Deluxe forge and set it up right when I got it. My dad gave me a small anvil (around 50lbs) and I purchased some hammers, PPE, a 1x30 belt sander, and some odds and ends. I had some rebar in my garage that I used to make a small knife that I was pretty proud of. Now that I spent some money on a setup I'm on the lookout for some cheap metal to try things out on which is why I started my search on railroad spikes. I found quite a few answers on that and where to go for scrap so, THANKS! A little about me. I'm 42 and have been working in IT for about 22 years. I live near UConn in NE Connecticut and have been here (in this town) for almost 10 years. I have been interested in blacksmithing since I was a kid but had no idea where to start or how to. It wasn't until the past couple of years where blacksmithing and bladesmithing has become a lot more popular that I REALLY looked into it. About 4 weeks ago I told my wife I wanted to get a forge and she really wasn't agreeable to it. Matter of fact she told me "you better not buy one". Well, just because she said that I went and bought one that night. When she went to bed. I was brave enough to tell her the next night after I had a six pack...six or more. Surprisingly she was ok with it and after she watched me make my first knife she was impressed with it. OK, maybe not impressed but no longer xxxxxx. Right now I'm making an anvil stand out of 4x4s. My anvil is on a wood stump that I had cut in my yard. It's not flat nor is it stable so I figured I would be safe and make one. I should be done with it today and back to forging this weekend! My apologies for the long intro.