Melw45

Members-

Posts

173 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Melw45

-

While I was buying my post vise the lady that ran the lot tossed in a loose hammer head. I took some photos of it a the marks on it. The taper to the striking face makes me think it is not a sledge. Have a look at the photos. Any info about it and advise about uses for it would be appreciated. Handle advise would be a help as well. Thanks for looking. Mel W.

-

Frosty All you said above is very good info. You seem to have a strong grasp of Dog psychology. Thanks for sharing! Mel

-

Yep our words are hurry up. LOL I read this to my wife whose feet are in them she cracked up. Then reminded me that my parents gave them to her. Did keep her feet warm in the cold NV evenings. The dog sweater was made form the sleeve of some good will pajamas. She was so small no coat could be found. Worked the pup stopped trying to curl up in a ball when ever we had her outside. and only cost $3.99. Mel With our other dog we would say ouch in a loud voice and stop having any thing to do with her for 15 to 20 min. She eventually got the idea on how to play with out biting hard. She still likes the hand game but no biting at all. I just hope the new one gets it as fast. But she is very young and seems to be just a bit hard headed. Has started to pick up stay at the door. Most times. Working on it. Mel

-

Thanks for the tips. One of the things we have been using is a kong with some of her kibble jammed in it. This will keep her occupied for a while. It also gives her something to chew safely. Our other dog has started to play with her as well. Mel

-

No she is not wearing it here in the bay area. That was in NV. It was cold at night and the little thing was just shivering so hard she did not want to go outside. Her name is Sammy and she is a terrier mix. We found her at the humane society that my brother works at. Thanks for looking. Mel

-

While in NV to pick up our new puppy I stopped at a roadside flea market and found some monkey wenches. Some pics below. Mel

-

JHCC Thanks for the info. That makes me feel better. Will look for more information on line. Mel

-

As I said In the it followed me home post, I was at a used mining equipment yard today. Got a vise and a 8 lb sledge head. It has smooth jaws that are 4 1/4 inch. The spring seems good and the hinge looks tight. Here are some photos. The close up is of the only mark I can find. Looks to be made in China. It will suffice for me to get started with. Thanks for looking Mel

-

Found a vise today. My wife said go ahead and get it. The lady running the used mining equipment yard tossed in the 8 lb sledge head. Will post more pics in the vice forum. Thanks for looking. Mel

-

I have some old computer cases with the u shaped covers. My subconscious keeps saying two or three T burners and some kolwool would make a nice blade forge. Rather like I see on eBay. Mel

-

Forging for now. Welding later. Need to learn hammer control first. Do know that this forge made the bolt hot in a short time. I know that there will be a larger forge in the future. I should have put a door on the back of this one. I was worred that the spring stock I have would not fit in the forge. I checked last night and it did. I hope to get some of it straight today. Want to make some punchs and small drifts. thanks for looking Mel

-

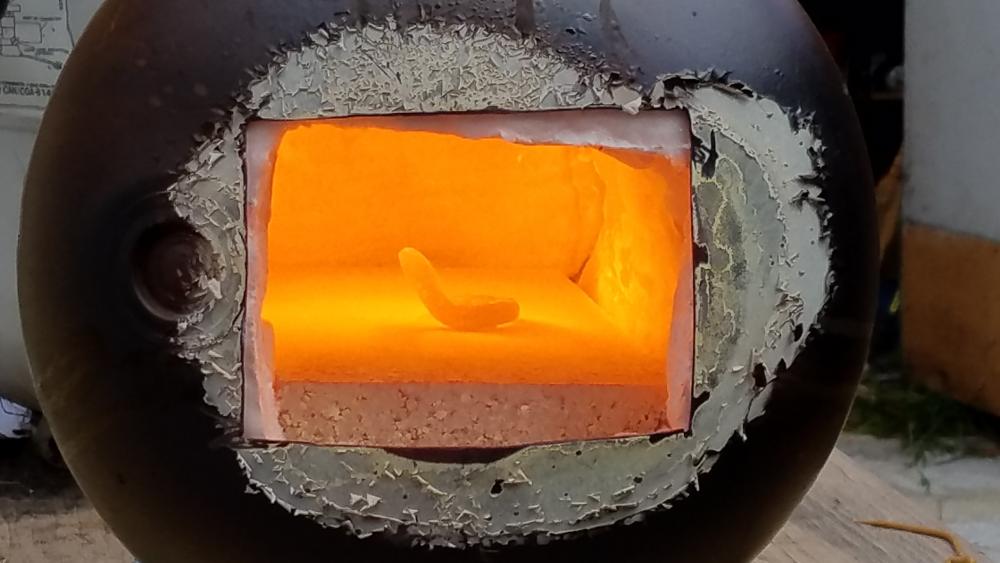

Wow with it in the forge it woke up! Would take as much gas as i could give it. Now for some pics. You can just see the mig tip in the burner. The next one is when I had just lit it. My wife came out to see How I was doing and had to take some photos. So you get to see watching a rusty bolt heat up. Next is a hot bolt in the forge. Last photo is what it looked like when I stopped, Kind of a snake shape. While I was rummaging around in my garage I had found some tong shaped things. I recall making them to put metal in to a foundry furnace I made years ago. Kind of worked to put the bolt in and out of the forge. OK I have learned some things, Need real tongs! Need to make the snake head first. This is some seriously hot work. Thanks for looking. Mel

-

That is why I put it away until I could tune it in my forge. I should get to it. Thinks for the insite in to fthe mig tip placement. Mel

-

I am planning to try that. When I tried with the burner clamped in a vice the flame would blow out. Thanks Mel

-

Thanks Frosty. Was going to try it with some of the intake blocked off. I want to see if being in the forge makes a difference. Not wanting to trim the mig tip if I don't have to. Mel

-

Thanks Dave I Have been frustrated with the weather. Tomorrow should be better. Give the new burner configuration a try then. I will get some photos then as well. Mel

-

Yep used the yellow tape. The wether has turned to rain the last two days. So since I am working outside it is on hold for a while. Thanks for the ffeedback. Mel

-

Out. Mel Thanks Frosty. I have. A .35 tip in there now. Did not trim it. Will try a larger one. Mel

-

Like the forge hood! Nice looking shop. Mel

-

.Got the parts out of the vinegar last night. The burner tube was all clean. The burner tube had a raised ridge where it was cut and threaded I ground it off on both ends. The conduit coupler I have for a flare did not clean just went dull. It was shiny before the vinegar. I don't think it is galvanized. Maybe nickel plated. Put it all back together today and found no leaks. Fired it up and it would only burn if I blocked more then half the air intake. Tried changing the flare position as well as the reg settings with the same results. Thanks for looking. Mel

-

Pulled it apart last night. My wife gave me a Tupperware container large enough for all the parts this morning. They are all under vinegar now. Just starting to bubble. Looks like the plating is very thick may take a while. Thanks for looking Mel

-

Well this forge is to be used outdoors. So I did not give it much thought. I will give them a good soak in vinegar. I have not found the T reducer like this one in black pipe. Unfortunately at this time I don't have funds to start over. I do have a big bottle of vinegar. The weather here is moving into a storm so not much work on the forge today. Thanks for the feedback. Mel

-

I will give it a try. Thanks Mel

-

Well I ran the burnner yesterday. Was trying to get it adjusted and found out the hard way I had a small leak. Got the gas off and tried to stop the leak. In the process of that I raised a nice burr on the brass fitting. That cut a 1/2 inch slice in my thumb and left a brass splinter. After I patched up the thumb I did what I should have done in the first place went to the hardware store and got the propane safe tape. Oh and a new fitting to replace the damaged one. Today was a bunch of honey do's . I will get it back together tomarrow. And address the pulsing. Thanks for looking. Mel I am using a conduit coupler as a flare. With that on the 8 inch 3/4 inch pipe. Setup with that it was pulsing or kind of buzzing. If I turned up the gas pressure the flame would go out. Will get back to fussing with it tomorrow.t Mel

-

Went to the locale metal yard. Found the springs and 1.5 inch rod in the scrap bins. The springs look to have been from some type of shock absorber. The large rod was in with some others that had been threaded. The rod I hope to turn in to some hardy tools.Maybe later make a hammer head from some of it. What is not in the photo is the 3/8 x 1inch flat to use for making some tongs fallowing the process I found on anvil fire. Thanks for looking. Mel