hawk18

Members-

Posts

46 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by hawk18

-

Sorry for your loss. I'd tell you I know how you feel, but I don't. It's always different for each of us. I also got to go through my dads tools and 'stuff' and took a sampling. I wish I could have got his anvil on the plane. I did get an interesting response from a young girl at the airline counter when she opened my old samsonite to check several of my old steel traps, three of my dads sheath knives and his old Winchester model 12. She got big eyes, said "Okay" and ask me to close it and lock it. Hawk

-

Just picked up this hammer for a couple of bucks. I wondered if any of you had ever seen one like it. Dimensions are: 4-3/4 face-to-face, 1-1/4 cross pein, 1-5/16 straight pein, 10-3/8 haft. It weighs right at one pound. The only markings are personal with an electro engraver. The one highlighted with chalk is the only one I can't figure out. The former owner worked his whole life in the saw mills so it's probably associated with that. Hawk

-

The plate is around 28 to 30 inches across, 1/4" thick. In use, it works good, but, if I had it to do again, I would move the 3" pipe all the way to the rear. I think that would make it better. With the length of the handle and the overall weight, you can crank it down tight. However, I haven't had to bend anything long enough to test it. Hawk

-

Do you think that grinder is rigid enough? (lol). And that anvil, and it is an anvil, will do nicely. Better than some. Hawk

-

They could be handy outside of their intended use too Work well on a wine bottle. No red stains on the counter or hot tub. Hawk

-

And I thought I was the only one. Hawk

-

What did you do in the shop today?

hawk18 replied to Mark Ling's topic in Blacksmithing, General Discussion

I started with a NC Tool model three, which I think was a Whisper Momma or a present day Whisper Deluxe. The forge and a bucket full of tongs, nail pullers and nippers for $30. From a guy pissed at his ex-brother in law. The first modification was to add a second valve between the burners. This, and a chunk of firebrick, worked better on small pieces. But, the open, shallow design was cumbersome, even with the pass-through door. Probably inefficient too. Enter phase two. Cut holes in both ends (sides). Add rails and doors and it's now a long skinny two burner forge. I'll add insulation to the original door and keep it closed. Can't wait to give it a try. Hawk -

What did you do in the shop today?

hawk18 replied to Mark Ling's topic in Blacksmithing, General Discussion

-

This was the final outcome. A 2" pipe nipple, slit, expanded and welded on. Then, hammered around the acorn to form a socket. Added the chain to keep the bigger pieces from falling off. Hawk

-

Here's a couple of shots of the setup. What do you think? Will a ring around the acorn be enough? I planned this with the idea of it being portable, but, at 295 lbs, as it sits, I won't be moving it much. Hawk

-

The mount sits on a base large enough to be standing on when torquing on a work piece in the vise jaws. Much like Thomas describes. That base is 1/4" steel and I have some black iron pipe I could cut and weld to the base to stabilize the acorn. Does that sound like it will work? I'll try to post a picture of it. Hawk

-

Finally getting around to mounting my leg vise and have a question. Does the leg have to be tightly secured to a base, or does it just need to be held in the xy axis to keep it vertical? Hawk

-

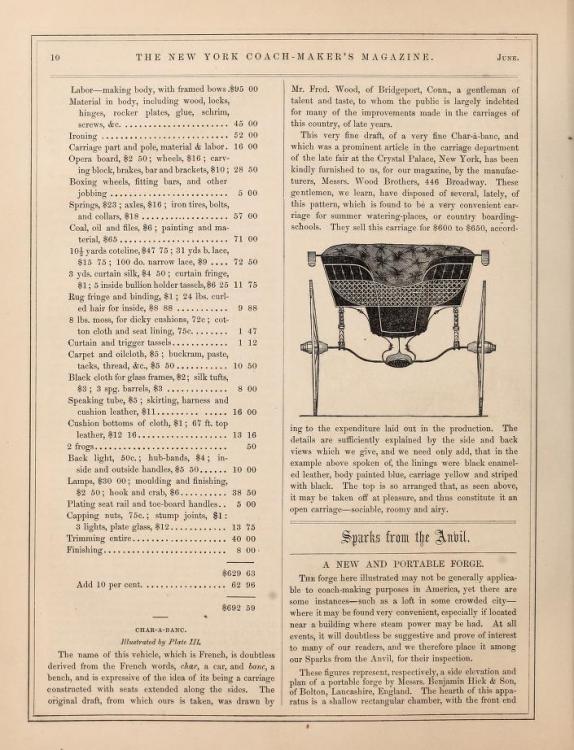

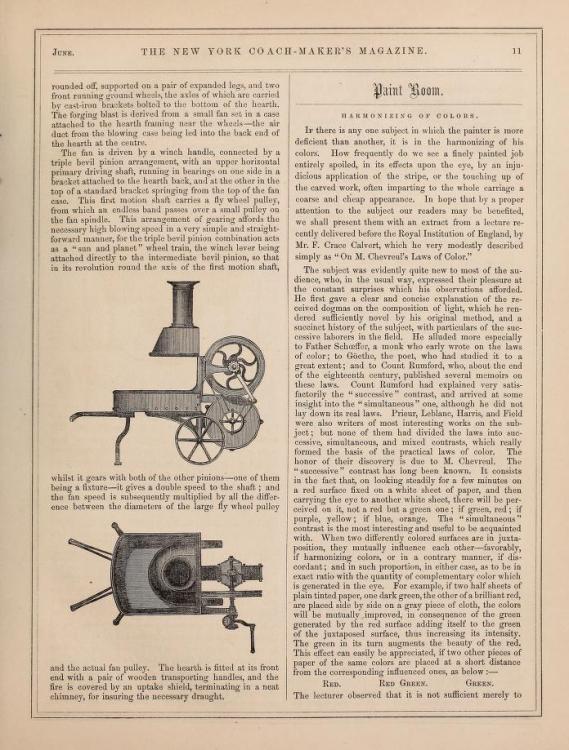

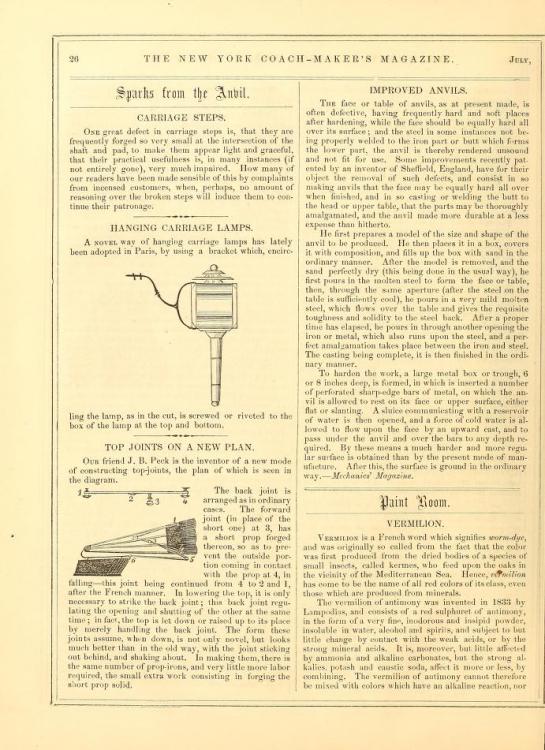

After someone clued me in on the Cornell digitized library, I went looking for similar, free digital books. I found others, including the Smithsonian library of rare publications. In that, I found "The New York Coach-Makers Magazine". It has interesting reading from the mid 1800's, including information pertaining to Blacksmithing. I'll try to include just a couple examples. I hope this works Hawk

-

What Thomas says, many times over. I have an abundance, perhaps an over abundance, of D2 planer knives. Some time back, I figured I would just treat them the same as O1. It didn't work. At all. I have made several knives by stock removal and they are very functional. But, it eats belts and is very difficult to polish to a high luster. Hawk

-

The group of hammers, note the center one, and traveler were my grandfather's. He was a boiler maker. The painted one came from a collection and I can't verify its use. It's about three pounds and both faces are concave. It's edges are too sharp to have been used on rock or brick. Note, the eye isn't "square" with the faces. Hawk

-

Looking for advice... Trenton Anvil

hawk18 replied to Sargos's topic in Anvils, Swage Blocks, and Mandrels

There is also a Covel saw filers anvil for sale in your area. A 300# beast. I considered both but the Trenton doesn't give me anything I don't already have and the Covel is too stationary for me at this time. Good luck. Hawk -

This is something I might expect to see when I visit Portland. I do feel a little guilty when I see the videos by the guy on his third floor balcony in Taiwon. Hawk

-

"How long" is is more defined by space than by will. I have the makins, it just takes time and effort to drag them out and put them back. But, there is a plan. Hawk

-

Rogue Valley. Central Point. I used to work in your area some. Still have a friend that lives in Del Norte county. Hawk

-

This is a photo of some of my Grandfathers boilermakers hammers and his traveler This is a hammer I picked up last weekend. Could it also be a boilermakers hammer? It weighs 2.25 pounds. The head is 3/4" longer than other ball pein hammers I have p Hawk

-

I'm not a blacksmith as much as I'm a tool nut. I love old tools and seem to have developed an addiction to rust. I imagine my fascination with smithing started when I would accompany my Dad to Mr. Jokel's shop in Dederick, Mo. to get plow shears built up and sharpened. His shop was amazing. With a center overhead drive shaft powering all manner of grinders, drills and such and a monstrous power hammer in one corner. He could fix anything, including my broken sheet metal toys. I have lurked around here for a while and find this forum to be a wealth of knowledge and information. I will continue to absorb the product of your sweat from the comfort of my living room. I will contribute as I feel I can. Regards, and thank you Hawk