-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

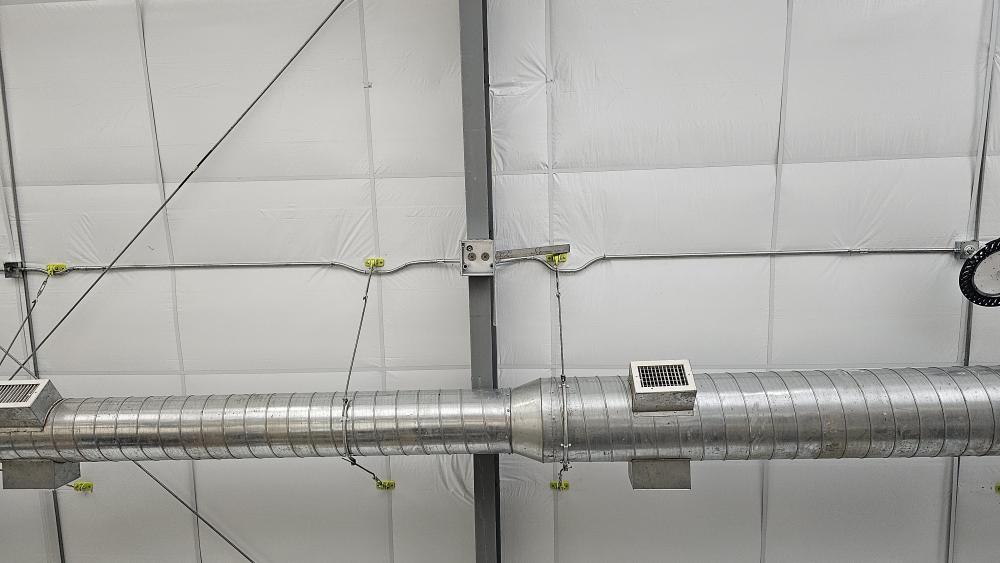

Was a very productive day today on the conduit. Was able to get a couple of complete runs in, few boxes.. Super exciting.. Can start to pull wires soon. -

Double joint Compass (steeled wrought iron).

jlpservicesinc replied to jlpservicesinc's topic in Member Projects

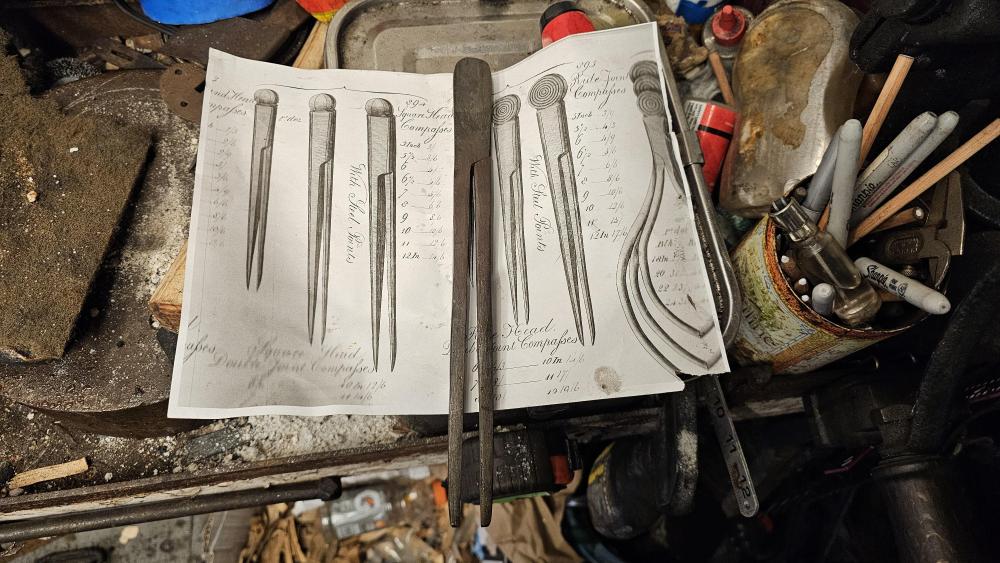

The good pair was about 2hrs of direct forging.. there was a lot of material prep.. Had to forge 5/8" sq down to 1/2" and then prep a horse rasp for the steel. I dragged out the Alex Bealer book to look and did not find the information referenced.. Do you know the page? Love to look it up. All my life I have never had an original idea.. It's always just a rediscovery or progression on a theme.. Tong making and rings was from the Cosira series, Tulip hinges from Alex bealers book.. It is funny how all things get blended together. I think the main thing about doing this so long is I don't spend time on an idea once I see it's not going to yield the results.. All 3 samples were about 6hrs total. This included a lot of metal prep since I don't have wrought iron in standard sizes. Sample 4 was about 1.5hrs since I had to follow it thru to see the exact results. Having a dedicated angle gauge for making these would be the best time saver.. As would a proper hot cut chisel designed for this.. There are a lot of time saving tools that would have been in a MFG's shop.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Jhcc. The one I made I put a jog in the handle. Aka dogs leg. This helped but in use it still wasn't as accurate. . Going with the jaws in line with the handle ended up being the best option use wise, but was lack luster so thru it in the scrap pile. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC How can the bar be held straight without twisting with the lugs on the sides of the bar? I looked into a bender like this 30 years ago and could never get it to work.. Maybe my hands aren't strong enough.. it always wanted to twist in my hand.. -

This will be a several post type deal.. I was invited to do a video for the EAIA " Early American Industrial Association". This would be filmed at the " Moses Wilder blacksmithing shop in Bolton, MA". I am a little tired of seeing the same thing in videos and with the plethora of newer smiths everyone has a yt channel and it seems they copy others' content.. Again, and again, and again.. Anyhow I said this to the EAIA rep.. That I wanted to do something different.. An auger or a double wing divider or a round draw knife.. Some;thing not seen nor shown.. It was agreed it would be a double-wing compass (aka Round head, Double Joint compass) copied out of the "A Pattern Book of Tools and Houshold Goods". ..Jane Rees and Elton Hall.. Of course, the caveat was it had to be steeled wrought iron.. I've never made a double wing/double joint in my life.. All the compasses (dividers) I've ever made were on the cheap.. Aka as fast as possible.. Never having made a pair before and having a filming session meant I had to sit down and figure out how to make them. I tried the flatten and bend into a U method.. No, go.. Not with wrought iron.. Steel would be fine.. Attempt 2 was the same technique but with higher heat and a little more lead-in.. Nope.. Was a bust.. Attempt 3 was welding on the wings to a main section.. This was also a failure.. If you know anything about this type of weld it's well known you have to be able to get back into the center to finish the weld after it shrinks.. (no way to finish the scarf.. So nope.. Failure.. It then hit me that I have to utilize the strengths of what wrought iron would offer and how easy it is to forge and forge weld.. Sample 4 came out perfect.. This was all I needed to be able to film and bring it to life.. I need to pick up a little angle gauge I can keep in my shop apron.. Having to remember what the angle is supposed to be from eye is no fun especially when filing.. This is where the filming left off.. It will resume next year in March.. With this said.. I will be making a new set and will film it in it's entirety. Here are a few photos.. You can see the failures and then that "aw ha moment".. Way easier now having figure it out.

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Reach out when you figure the date.. I can see what I can do to oblige you with a visit.. Be great to see you.. Many items have been forged since last visit. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

JHCC I'm deathly afraid of heights.. always have been.. Driving over a bridge can be a painful experience.. Steve, I just had to undo all the strut clips and feed it in from the other end.. I was able to turn the Bend to the side some and get the flex needed.. I was just hoping there was an "easy" way.. I knew I'd have to redo the work I already had done and was not wanting to do it again.. I marked everything before I took it apart so made going back together a little faster.. I am going to add another 2 runs of conduit from the main wireway.. I need a box for the left side lights .. George.. I feel you.. I can't even watch a movie where they look over the edge.. I jump back in my seat.. I don't do well watching things.. I do alright doing them.. In other words I have to do the thing to trigger the part of my brain that allows focus and then can do.. On the couch or in the car I can't tap into that area of the brain.. And yes, age is a lot of fun.. the alternative well.. I have no photos of today work.. but every step is a step forwards. I still have about 40 pieces of 3/4"X10' EMT.. So plenty to finish what I started.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Youch.. Wow, are they expensive.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Larry, It's amazing how many people claim to not be afraid of heights (AKA OK) and after being in the "women" lift 20min they are clinging to the side.. It's a different experience for sure because it's not solid, and even people who are OK on a ladder will have a change of heart in the Lift.. There is no sense of solidness.. The nice thing about this lift is the 66ft extension can be straight out vs a modern machine that will get tippy.. At 66ft though it's a lot like a diving board, trampoline or air bouncy house.. If you move quickly the basket will also move away from the pressure. Steve, so basically it just comes to hanging down the wireway and feeding them in just like I've been dong right along.. I've found that on straight runs of conduit, there is oftentimes enough sag that the conduit can be pressured more to bend to make up that 1" or so distance needed (shrink) to insert.. Where I find there is a problem is when in an area like this with the 34.5 degree bend at the ridge completely has the easy bend going away or towards the top vs the bottom.. if I had 2ft above the bend it would slide right in. Anyhow I was hoping there was a trade secret that was known and shared with other professionals that was kept from the public at large. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Gewoon Ik, you are very welcome.. Great seeing you at the forge.. I was able to get a little more conduit up.. I am not sure if there is such a thing.. A slip coupler/connector for EMT? I keep getting to the end of the run with a box with no way of installing the conduit into the fitting unless I undo the box? @Steve Sells any ideas? On fitting the very last piece of conduit before a box? Working by myself and feeding in conduit is not much fun. This is where I stopped before undoing all the conduit strut clamps or the wireway.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

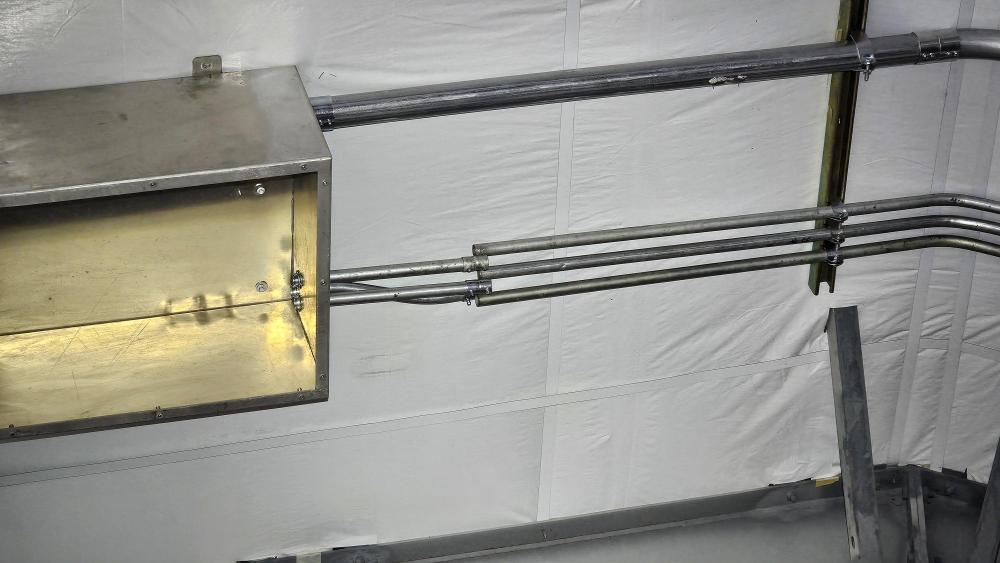

The tape I ordered worked a treat.. Will see how it does in the long term.. on installation it actually clung to the grey irons very nicely.. The stuff from Bayliner did not stick great.. I was also able to get the huge wireway installed with the 2" conduit so now can do the light switch run of conduit. Gewood Ik, the space that is open at the top of the end wall is insulated above and sealed from the outside. The white membrane is attached at every possible point so is very well sealed.. Now that I have moved this far along I will also find some time to finish those very top sections.. problem is there are supposed to be insulation hangers to keep the insulation from sagging down in the wall.. On this end wall there is no place to put the hangers.. The hangers should have been installed when the outside siding was being installed.. Another point that was never mentioned.. So I have to figure out a way to mount the hangers.. I was thinking of mounting the hangers on some of the screws that come thru and putting a piece of foam on it and some gorilla tape to hold it against the wall.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

I like your thinking but can't do it.. The propane infrared heater. Not enough room above.. And can't have anything below.. The air handlers are only like 24X24X by 36" or so.. Plenty of room and can be speed adjustable and contain air cleaning filters.. The window will be back.. I have to order a new one.. So I need to reach out to a few window MFG's to get a price.. Last time I priced, one place was 4400 installed the other 2600 installed. I don't want tempered glass.. When dealing with tempered glass that just right impact (barely anything) takes out the whole window. But if I use plate glass it needs to be coated or protected. Also many companies say.. Lifetime warranty and what they are really saying is the lifetime of the first window.. Once broken your on your own. I want a triple pane 60X65" IIRC.. On the metal side of things I'm by myself so holding the sheets up for fitting is tough and measuring for layout and cutting is slow.. With the sheets in and screwed down in a stable place I'll mark out the cuts and pull those sheets that need cutting off, cut and replace.. As it stands now.. Having the area blocked off from wind/rain/snow.. does keep it a tad warmer. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Not much.. Just the top 3 sections of the east side of the building.. No great way to do them and no instructions.. With this, Even with the little bit of non-insulated areas up at the front eves of the building.. The school is super warm.. R38 roof and R29walls.. The membrane eliminates any drafts.. I keep it between 60 and 65F.. Good working temperature.. The furnace is a multi-fuel unit.. I burn "used oil".. 1/2gallon per hour.. When I'm going to be having the big door open for work inside the building while running the manlift I'll put some wood in the furnace a few hours ahead of time and then burn wood as it's a more consistent heat.. Even with the garage door open 4ft at the bottom the 65F is easy with it 35F outside. What the shop could use is an air handler.. This would be great to blow the heat down off the ceiling. I have plans for a few filter units with the outlets aimed at the floor.. But that's in the future. Before I installed the furnace duct work.. I just had an elbow with a flap of cardboard on it and this was not very good at all.. It would be 45f at the floor and 105F at the ceiling.. I thought the heater duct would help and it does.. Quite a bit.. but.. The air flow out of the duct work is not forceful enough.. Enought velocity.. Its very subtle.. The whole shop is 65F at the human level.. So thinking of installing a larger blower.. This will circulate the heat up top better and make the whole system more efficient. I know there is a balance between too much air and the temperature rise of the furnace. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Hey, Thanks Larry.. The long 1ph runs are so much easier.. I don't like to make scrap.. And laying out the 3ph stuff kinda used some of the scrap pieces.. Meaning cutoffs .. That and not having a working knowledge or what is considered standards of practice.. (aka short cuts) My budget flew south.. Been putting in the mega time so a little tired.. Big push on the siding and insulation front.. Having to get the siding up to continue the electrical.. First was to remove the old window.. This window was forced into the opening so distorted it some.. Taking the window out will allow for pressure to be taken off the steelwork and now things can be screwed together in their correct positions. I removed the 1/4" tapcon screws from the bottom frame and redrilled the holes for 5/16" and put in 6 new screws.. The 5/16" screws have way better mass vs the 1/4".. I then put up the silver faced 1/2" foam insulation into the bottom cubby and put the insulation hangers in. Then put the fiberglass in. Taped it up and installed the membrane. I then installed as much of the double sided tape as I had which was just enough to get to the height of the white metal siding. I then installed the siding.. I decided that doing this job by myself is one of the more torturous jobs there is.. Luckily the panels are only 7.5ft long.. But holding and screwing them into position and cutting them is a problem.. Lucky for me this area is the last tough one with many cuts and cut outs. I ordered several different kinds of tape to put up the rest of the membrane.. From the Insulation company they are 125.00 per roll and 1 roll doesn't quite do 1 bay.. I ordered 2 extra last time thinking it would be enough and NOPE.. I ordered some stuff off Amazon.. will see if it works.. The insulation company now has a NEW England rep and he reached out after sending a message.. I'll know today if the Amazon ordered tape will work.. It's 1/3rd the cost.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexandr fantastic work as always.. It's great seeing your consistency.. Great work day in and day out.. Today was the first time at the forge in a while. I had a broken strap hinge come in for repair. Also attempted a pair of wing dividers out of wrought iron.. This is some really nice wrought iron but it has a tendency to fracture across the grain. First attempt ever at making this style.. Happy with the process overall.. The wrought iron really makes me push my forging prowess.. I have a video film session on the 9th so I have to dial it in by then. If I can't get the wrought iron to not fracture I'll just make them from mild steel. The tips are tool steel.. I'll make a set and etch them.. should be cool. The dividers were forged to size.. There was no allowance for material to be removed in finishing more than just a clean up. This means all the angles were forged in.. I might have pushed the level of prescision past the point.. With closed dies it's easy.. But open anvil forging.. Well. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

It is an interesting point about spending a bunch of time and no one really seeing the results.. I suppose that's where the "luck" of doing it all comes in.. What gets me, is how long something can take.. From inception or design (figuring out something since there are no directions) and then doing it.. Then having to take it apart because something that should have been there first (no directions) has to be put in before you did that next step.. Rinse and repeat. Many, many times.. You think you get finished with something.. NOPE..,. Some of the most simple of things in a wood framed or brick/block framed building is a major undertaking in this steel building.. Because of frame spacing, etc, etc.. anyhow, every step is a step.. Spent all day in the manlift yesterday so last night I felt like a druken sailor.. For those that know what I'm talking about hats off.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Want to, have to.. Those lines get very cloudy.. $$$$$$ If one has $$$$$$ then anything is possible.. If I had to pay someone to do the work on this shop/school build I would not be able to afford it.. Want to.. When I started this idea some 35 years ago it was a want.. 15yrs ago when I put this school build into motion it was a want.. about 1/2way thru for a lot of it, it became a "have to".. Not only because of the money I have tied up in the place, but also because if it's not finished it's a space that would be useless except for storage.. This would not work well because then I'd just sell all the blacksmithing equipment so then would not need storage. LOL.. $$$$$$ is really the dictating facet for all of it. I am making progress on the electrical for sure.. It's hard to believe the school is nearly complete as a building. There is something about doing "good work" that to me is very satisfying. Good quality work. Running that 2" conduit took a while.. The bends are neither 45's nor 90's.. Going to be stunning when I'm finished. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

I wanted to run a trough.. My Master Electritrian friend told me adamantly to avoid it. And here is what I found: Sadly here in the USA code and such have limits on what can to be used. and even go as far as mentioning it has to be UL approved and stamped or coded as such. Its expensive if you buy UL listed cable tray from what I looked at or found. I was going to make my own out of old walk way.. which would have worked a treat.. If the cable tray is installed then you got lucky.. I am not a builder, heating/plumbing person, nor electrician. So all of it is my first time.. as is learning about all the codes involved. AKA no real guidance.. Just told at ever turn " you can't do that". The largest percentage of "Hold up" is figuring out why, where and how things should or should not be/go. What this project has taught me is this. People will tell me " You can't do that". nearing 100%. But percentage-wise around 0% are willing to help or even offer real suggestions on how to do something.. In today's world with all the information on the internet, there are certain professions that keep things under such tight wraps (so secretive).. Often times I think it's steeped in money and the worry that the job really is very simple and they are worried if people really found out, everyone would just do it themselves.. As for the conduit, and runs.. Once the first piece is made, it's just copying the rest of the needed pieces to the first. So 6 runs.. Just copy the first run.. If you make 90's remember to add 2 inches on each other piece running from inside to outside.. Or removed 2 inches in length if ran from outside in.. Which means if I have a bend on the side conduit and the measurement is 50 inches to the bend.. ON the next bend to match the corner and have space I need to make the next bend at 52" on the next run at that original spot. I'm terrible with the bender as I'm not used to seeing things backwards.. I have to force myself to turn the bar the opposite way of what I think is right.. Even with such little use I know my conventional thinking is wrong so just work at not fighting it.. As long as I do this, the bends come out very nicely. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Today was putting up strut to run the conduit from the left side breaker panel. This will supply 240 100amp to the sub panel on the far wall as well as be the side that is used for the lights and for the power on the sides of the forges and workstations. The right side panel is powering the 3ph items and the 240volt 1ph stuff like machinery. It is interesting how long it takes to finally make a decision where things should go. Never having done this before and then reading the codes with exceptions.. it's daunting. Hard to believe this is nearing completion. Got the first run of conduit up that will feed the 4 gangs of lights. Ordered the 4 gang light boxes too. I should have just enough strut if I plan well.. If not I'll have to buy another couple of pieces. It's going to be very close. I need to order 3 more 12x12x6" enclosures.. That will complete the junction of the wiring going over the grey irons or upright frames. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Shaina, Looks like something is a little to tight on your forge drive.. The flywheel should keep spinning even with that little bit of lever crank.. Looks like there is some resistance someplace. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Well, after some varying this and that situations I was able to get back onto running EMT for the lights. The Manlift was giving some fitz and quirks and needed to be gone thru.. The manlift has 4x4 brakes that automatically engage and disengage when the joy stick reaches a certain position. The joystick is designed to creep the PWM on the solenoids to vary the speed.. Last summer the unit worked as it should but this fall, It was going from brakes on, to brakes off and full speed instantly.. 5mph is not that fast on a bike, but in a 27,000lbs manlift with 35ft out, its super fast when you need only to move a few inches. first time nearly threw me out of the basket. So cleaned all the connections, checked all the wiring with no results and then decided it was time to check the all ready adjusted Joystick.. And low and behold.. The adjustment at the joystick did it. Few weeks back I ended up with a flat tire that somehow holds air perfectly and now the joystick that is out of adjustment.. Gremlins.. thought I was punked on the tire... Whos to say. Getting better at my emt Saddle bends.. The last one I did even looked respectable. By the time I get good at them, I won't be doing them again. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Hey, I was waiting for you to share your experiences.. There are no mystical or magical aspects to making hydraulic hoses.. It's not an archaic science either.. If you use Kurt products you go and look up what the crimp specs are and crimp to those specs.. Every MFG has look up tables for their products.. Some of the crimp machines that are made by certain MFGs have simplified the process but using color coated items.. Use this crimp ring with these fittings and this hose. Like anything one needs to do the research and gain the knowledge to use any type of item safely.. Watching videos of people test cutting with Katanas is always hair-raising.. Scary to say the least. And yes, there are many, many dangers with hydraulics especially when ill-trained.. 2 people.. Go start the unit and push the lever until it bottoms out.. I'll then run my hand down the line to see exactly where it's leaking.. Not smart.. But accidents happen everyday.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

that's really handy.. Do they have a service call fee? What i mean is.. Do they expect to do the whole job or just make the hose?

-frameat0m19s.thumb.jpg.c4190d8fc9845a3f144e9d202f309015.jpg)

.mp400_00_1520231127-66727073_6375.thumb.png.e1d2b360eeef2345691e3b20db077014.png)