-

Posts

5,754 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Frosty, because this is a forced burn chamber unit, the exhaust is pressurized. The stack temps are pretty high because of this factor.. It's not as efficient as a "draft over fire" model which uses a chimney and barometric dampener. What is good is this can be put nearly anywhere and ducted to outside even with nearly a 90 degree elbow and ran 50ft out the side of a building easily with some upsized pipe. The stack temperature even at the 14ft mark with 20F and wind blowing temps is 180F at the top. The 14ft is to get the smoke as high up as possible to keep it away from the blower intake. Or else it just blows the smoke into the trailer.. It's an interesting machine.. Basically a "home or building" hot air furnace with the same cold air intake and heat output into ducting. Both the intake and and hot air output can be ducted as well as the chimney.. This model at 300K is designed to work even at low temperatures and still output ample amounhts of heated air. If you look up "indirect oil fired heaters" there is a ton of great info out there.. Some of the newer units use nearly the same arrangement for burner setup.. they use a flame retention head held in a tube with little windows on each side of the tube to collect the right amount of air. These being dialed in at the factory.. The output is very clean but these types of heaters are not as efficient as the totally separate burner models which use a separate blower.. Some of these burner/blower units use a venturi assist in the stack since they are "Draft over fire" And yes.. Having a heater blowing warm/hot air out into open space is still useful when working on equipment in the cold. I love the crispness of -10F to 16F winter air.. I really enjoy it.. But working in it.. Ah, not so much.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice key.. Forge brazed? -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Frosty, thats the thing right.. I'm super happy with how it looks and overall it functions well "enough".. I have a 14ft stack on it now.. but when the wind blows oil smoke is pretty heavy and it floats low gets sucked into the blower and ends up inside the trailer. Much better than it was but still. Be really nice to find an owners/service manual.. I just got spoiled with the heater I made.. it was smoke-free and had plenty of heat.. The main part is limited service life.. What I mean is.. In another few months, I won't have a real use for this heater except to heat space and tractors when I'm out in the snow fixing them.. Which can be a really nice thing.. could have used it last week when I replaced a wheel bearing outside in 20F.. I guess this becomes the true answer since I have all the parts and burner.. It simply means having to adapt a holder plate and a fan shroud since I won't modify this unit.. I'll just make new pieces to keep it original. Some old oil burner tech guy would probably have an answer as to the question quickly in terms of how to clear the smoke.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks.. On the subject of creams.. I like the Goldbond medicated.. I get alligator skin and funky breakouts this time of year. I've tried all sorts of over the counter and even some prescription stuff.. Nothing would touch it.. On a whim I tried goldbond extra strength and a week later it was cleared up.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Heater is back together and a full 3hrs of use today. While its certainly a lot less smokey, it's still not burning as cleanly as I'd like.. I have a burner I can fit since I had all the parts to make a long tube burner.. The real argument is, do I spend the time to make this 100% of what I think it should be.. Or should I just leave it alone since by this time next year, the school will be up and running and I'll have someplace warm to forge and won't need to heat the trailer to work in. I know the true potential.. Thats where I fall apart between logic and reason. Install the retention head oil burner and have a more effective and efficient portable heating unit (which is nice when outside working).. Or leave it alone and suffer with the extra smoke and smell.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

John, very nice.. Steady improvements.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

I forge with the left hand too.. But it's just roughing stuff out.. Sadly I'm just getting to be at forging speed after all those years away.. only to get this far and the accidents.. Eh, I'll push thru or I won't.. Time will tell.. So I have to ask because of where you are at.. Your trying to make a Tanto? Wakasashi? with traditional HC outer skin with inner softer metal? Don't take this the wrong way.. Your kinda going about it the hardway.. Or the ultimate skill way.. I often lose heart when I see someone trying something in which the chances of success are very low.. The best way is to forge a Sunobe and forge from there.. Put in all the correct markers and lines and then go from there. I'm a huge fan of "Success breeding success" and within a few blades, you would be right where it would be much easier. Way, way back I had experimented with taking the little shortcuts and what I learned is, that there are no real shortcuts if the desired outcome is something that is "known".. IE chasing after.. Way, way back. I had done the very thing you are doing on more than a few occasions.. A few of the blades I had forged right thru the HC on one side. Yes it is possible. At welding heat, each blow of the hammer has to be counted.. Also a flat faced hammer is preferred vs rounded face unless trying to manipulate the grain.. Anyhow, keep after it. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Chad, thanks.. Love the hearts and hair pin.. I'm not sure exactly what will happen with the hand/wrist. I keep forging but it's awfully painful. Today I picked up the large hammer and it really yelled at me. Peening is where it's the worse.. Having to control the hammer in flight to the target is excruciating. With that here are the items I forged and finished today. The handled cold cut.. Yes, this is a cold cut, not a hot cut. Tempered correctly I've never seen the need for a wide cold chisel affair.. This is forged a little thinner than I'd like but will be dressed back more after a few uses. Wanna see if I can get away with the edge being so thin with very little side to side support the blade has a () shape. Forged from 1.25sq 4140 by hand the eye did the old fashioned round punch way.. I filmed it for a video.. I'm going to be at the ABANA conference competing in the grill comp and we are making/using different tools for others in our group to try. As forged and then a little cleanup. Still not a fan of going at things with the grinder but have my new-to-me Bader clear space running with VFD.. Just wired it so get to test out. The chisel was all done by hand steeled mild steel. Socket welded with floating mandrel vs horn. No grinder here.. I did the initial cutting edge on the grinder though. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

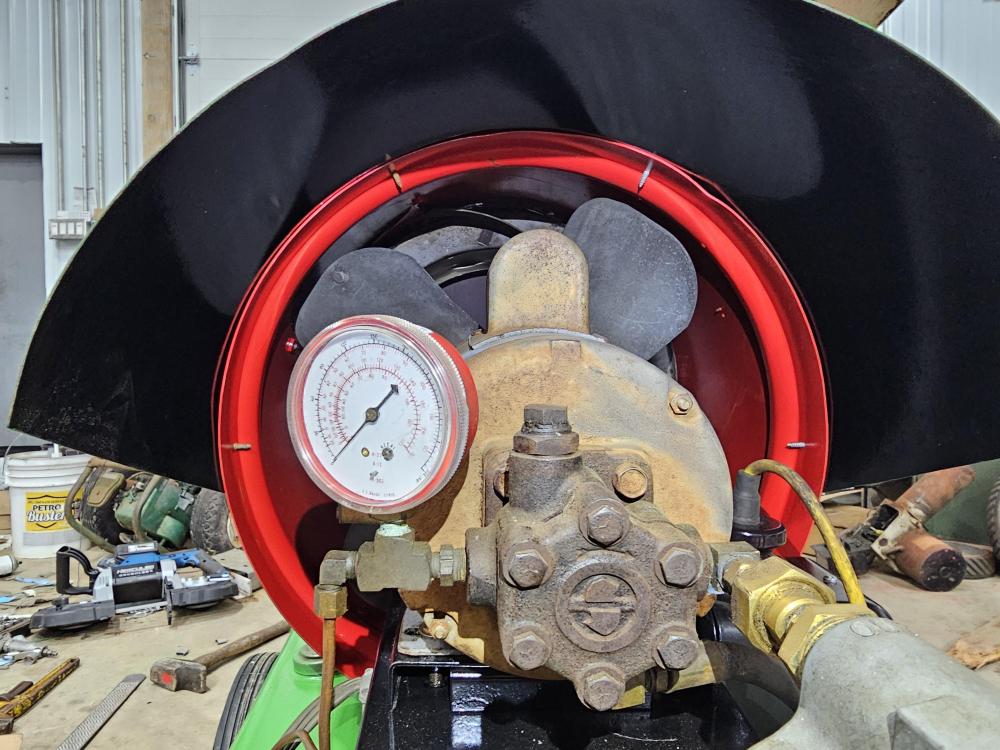

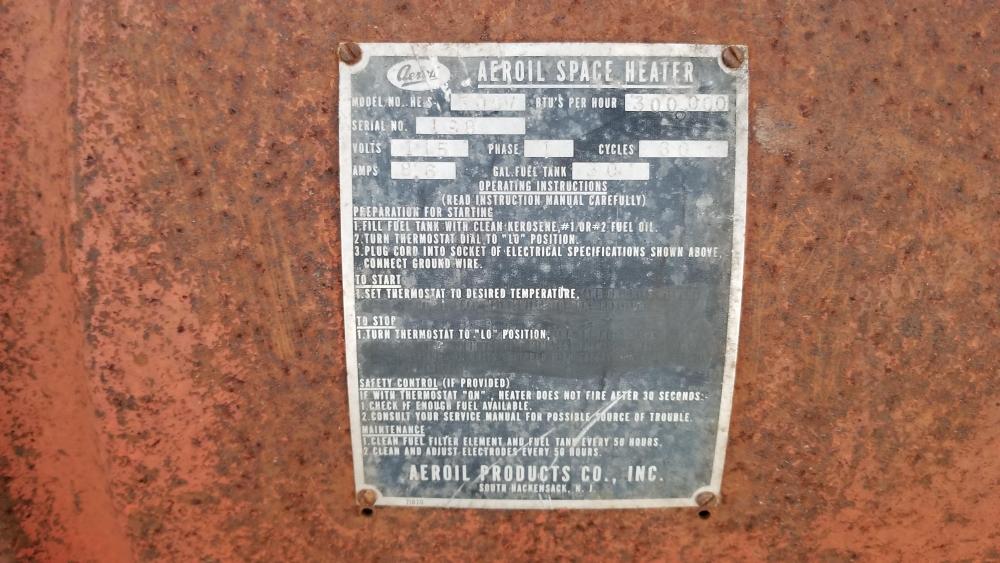

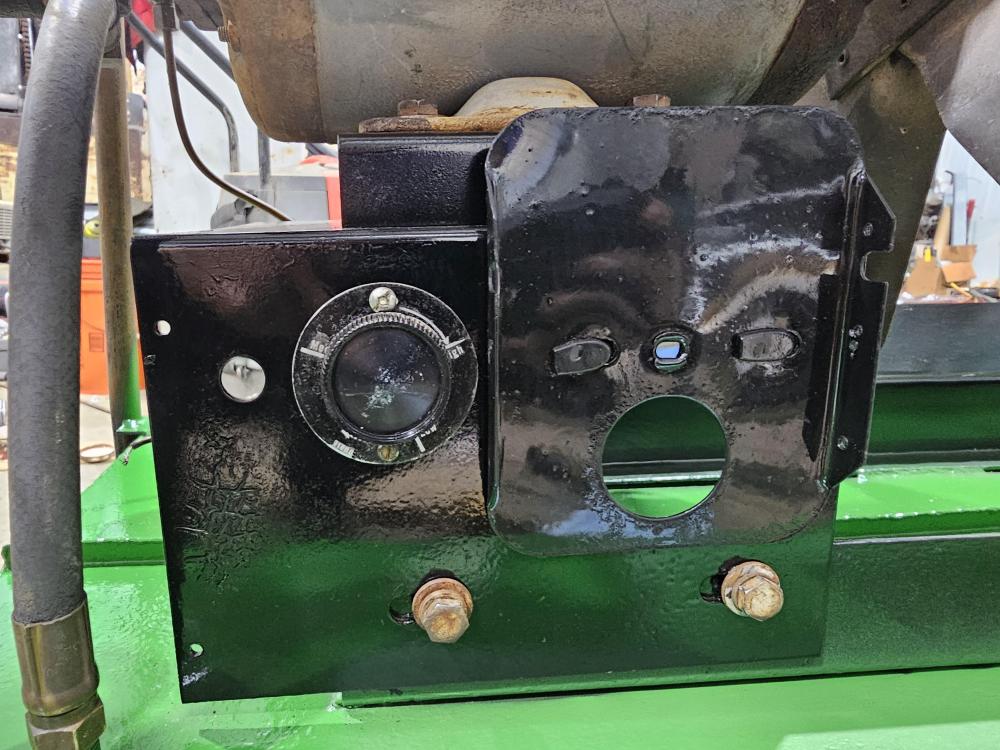

Well the heater is painted and assembled.. I have to hook up the thermo switch and then it's test fire time. I'm hopeful that the smaller nozzle will take care of the smokey stack. If not I'll look at ways of putting a modern burner in without destroying the unit.. Sheet metal is cheap and this design leaves some room for expression. I've included a flyer by Aeroil.. They loved green, red and black.. Seems like everything they made were those colors.. I hope the paint darkens up a little more but I think it's about as close as I could get swatch wise from areas not exposed to UV and rust. Do you guys know anything about Thermo-snap switches.. Looking for a model number.. 24227, 120, and 11/67 mfg? There is also a 11-13 -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Thanks Steve.. I'm not really sure what came first.. Frugality? I think.. When I was 3 I asked my mom for some money so I could go eat.. She looked at me and said " Go work for it".. We were in an environment where at 3yrs old I could in fact go to work and make the money to go and eat.. I soon learned if I don't spend it, I don't have to make it.. Lucky I suppose that money has not been the only goal.. (getting rich is not a goal). But, it's also a down fall.. Getting older and this past year has been brutal physically. So, now I'm super envious of people who work for a company with paid sick time, paid vacations and such. One of my more archaic sayings is " Do with or do without".. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

George.. Nothing involving the government is simple,, Well other than they will tax you on nearly everything they can. I could get a tank, and then contact all the correct government officials, file for my gas tax stamp, etc, etc. and after all the time not really be worth it.. Heating oil is red here.. Not sure about off road diesel.. John, given time, money or both.. You can burn what ever one wants to with enough research and equipment. My used oil burner that I use to heat the school can burn any oil.. Veg or fossil. If one wanted to invest in a used oil burner and attach it to one of the expensive IFH (they take a regular oil burner vs special parts) than it can be done. The furnace in the school doesn't smoke nor does it smell like burnt oil. Look back at my inderct fired oil furnace.. It worked really well.. Had a .65 gph nozzle in there and a24gallon fuel cell.. Frosty, the heat exchanger/burn chamber in this old furnace is in very good shape.. No cracks, holes or the like. It seems in some ways the older items were made differently. Heavier maybe.. The new retention head burners burn a little hotter and they only use enough metal thickness to have it last long enough as you pointed out. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Kerosene here is nearly 5.00 a gallon.. Vs road diesel at 4.09 gallon. What you are calling Petroleum might be our #2 heating oil.. #2 fuel/heating oil and gas station/ petrol station, pump diesel are nearly the same and can be used interchangeably. the only real difference is they add a color agent on heating fuel.. The difference here is that road fuel is taxed at a slightly higher rate. Kerosene is a cleaner burning fuel as it's more refined but I'm not willing to pay the extra amount.. If the burner is tuned correctly it will burn just as cleanly with road or heating diesel fuel. Aeroil designed a bunch of heaters and burners that were designed as multifuel, meaning kero or diesel or heating fuel. Be nice if I could actually find a manual for the heater.. It might have suggestions in it for just such a thing. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

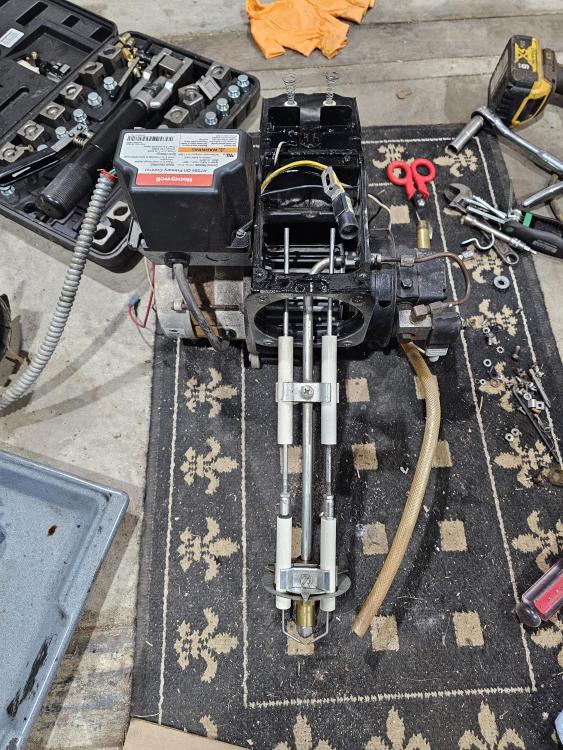

The original rating was 300K.. Yup, good for large area.. When I fired it up it was super smokey.. I don't know if this is typical of this vintage oil burner or not.. But, I'm not happy with all the smoke.. Smells like unburnt diesel.. I'm sure there is unburnt fuel.. So have installed a much smaller nozzle .60 gph with 45d solid. I'll see if this cleans it up some. There is no air adjustment just nozzle size.. I know that a .60gph nozzle does not put out 300K btus.. The trailer only being 8x8x10 heats up super toasty quickly.. Quickly enough I open the roof vents and the back.. The indirect heater I made worked super well both in the school and heating the trailer and burned clean.. So the clean burning is where I'm heading. If I can't get this to burn clean, I'll start looking at ways of installing a modern retention head oil burner and do away with the older tech.. I hate modifying older tech so will try to figure out a way that won't destroy what's there. I just stop and get 5gal at a time. I don't use enough diesel even with all the equipment to justify a bulk storage tank though when I see one cheap enough I'm like oooohh.. Manlift, mini dozer are gasoline.. The Kubota B6000 and IH 3800 are diesel but don't use any of them enough for bulk.. George what model do you have? Have you taken it apart for maintenance? -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Well it's been sometime since an update. The lights working has led me to work on another project since I'm still forging in the trailer and it's winter.. Heat is a great thing and to heat the trailer I used my self made indirect portable heater.. But, last year a guy had an old commercial one for sale free so I went and picked it up and have been working on getting it running. And since I now had a commercial made unit. Tore the unit I made apart and thru most of it in the scrap heap.. Once I figured out it was the transformer that was bad I fired it up but it is awfully smokey.. Being an older burner without a retention head and no way to adjust the air flow to the burner I ordered some smaller nozzles.. With this, I feel badly having a piece of history just outside weathering and decided it needed a new coat of paint to help it survive another 70 years.. So cleaned it all and painted it.. I believe these are the original colors though it's hard to tell.. The color swatches were from areas not exposed to light/enviroment. The green looked correct on the computer monitor but looks a little bright.. Maybe it will darken up a little more. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

This type of sandwiched knife/sword you are making is a tough one.. The welding has to be even side to side and the likelihood of a warp is off the charts.. This is a great time to learn about tension and how hammer blows are used to change this tension and straighten the blade after hardening and tempering. Yeah, not sure if forging therapy will make it better or not.. It does show me the limitations at this current time and then I can make adjustments to be still functional. Today I forged a little again. Few more samples.. Ones showing how the scarf makes a difference in how the item turns out, a hinge barrel, and finished the socketed chisel. I also did another set of leaves and was overall happier but it's a huge struggle as the hammer is everywhere since I can't apply any kind of support in the swing.. So once the swing launches, there is no correction during the swing. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

yup. Nearly lopped off my right hand at the wrist. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

I have a demo coming up in a few weeks at the "Conneticut Blacksmiths Guild" which will be a the Mystic Seaport Museum. The shop there is a wonderful place for a visit. I asked the person who reached out what they would like me to demo.. Interestingly she said "Forge welding". This falls in line with the last class I did at PV and a future class coming up in ME a week before the ABANA meet in PA which is it's 50yrs celebration. I will be there both competing in the group comp, but also demonstrating and teaching" Hinges".. So since I nearly lopped off my right hand I figured I'd better make up some samples of what I'll be teaching/demoing at the CBG meet.. (Since certain motions are extremely difficult/painful.) This is kinda cool because it seems nearly all the demo/teaching events will revolve around the same basic skill of forge welding.. So yesterday I spent a few hours making a bolt, a welded socket, a leaf duo and a poker point. My hammer swing is funky because of how maimed the wrist is, but still able to forge.. Just not peen that well. Will need more time with the hammer or choose a hammer with a larger/wider peen. While the overall shape of the leaves are decent, the spine running down the middle and the veins are not what they should be. I'll get in a few more practice sessions and try to dial it in more. -

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Coming along nicely. Last we spoke it was still conceptual so it's great seeing it come to life. Photos of the failed hinge you originally mentioned would be great too. I'm a visual creature. I think most Blacksmiths are so seeing things is soo much better than reading a description. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

gewoon IK, Hows about some photos.. I know your have been working on some projects.. Be great to see them and how your doing.. Shaina nice twists. Your pig tail scrolls are getting better too.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Pretty nice.. but aren't you missing a piece? The part that acts to keep the bar against the door.. Also known as a staple or bar keeper.. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Thanks George.. Very kind of you and much appreciated.. First day forging again after nearly lopping off the right hand.. Felt really good swinging the hammer mentally.. But had to really pay attention to how each swing felt and the level of power and angle. Latticino It will be a custom stainless steel double-layer affair.. Will have the inner flue and then the outer collar.. I'm going with 12" sq single wall for the flue/stack. I've measured the temperatures of the stack and I can't find anything over 210F on the forge in the trailer even with really heavy wrought iron hammer forging/welding. There is enough air volume going up the stack.. I have started collecting 12" double wall stainless steel commercial (metalbesto) but don't see the need other than what the rule book reads as for "Coal heating appliance".. in the code book.. A forge is "not" a heating appliance.. Meaning or pertaining to the "heating of the building".. So I'll make the thimble, get everything hooked up and then call in the fire chief to talk about it.. The thimble I'm making will accept the metalbesto pipe soooooooooo..... If you have information pertaining to open coal forges and code I'm all ears.. I looked for 5hrs trying to chase down anything I could and even reached out to an old guy who was around in the 80s doing code.. He said there are "no regs" on coal fired open forges.. And since they are not used for heating a space the current codes do not apply as a "heating appliance".. LOL.. We know what that means.. LOL.. NOTHING... The thimble will be fitted on the diagonal vs square to square (chimney/building) this will allow it to divert the water and snow on a sharp uphill leading edge.. I'll also make some Sharks fins (aka crickets) to also split the snow when it starts to slide.. The thimble will have a rather large thick wide flange on top that will rest on the roof and be sealed with calk being screwed thru the roof and into the subframe.. Over this will be a Dektite silicone conformal seal . The inside portion will just have a sleeve that fits inside the secondary down tube.. What is not being said, is the opening will have to be framed in with the same metal Z and C channel that the building is made from.. The only 2 places that are structurally easy, are the very peak and then about 4" in from the bottom of the eves. This will have to be completely framed in with the Z and C of the original building so all of it will be steel. Frosty 4/12 pitch The original design was 2/12.. But told them 4/12 minimum. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Great suggestions. George, everyone should evaluate what and where they are comfortable. And take the needed precautions. My experience with outside help/professionals is lack luster. As a male you don't get the same "positive reinforcement" from other male trades professionals. This is a sarcastic statement just in case it was missed. No one will do as good as job as I will and exactly as I want it. Most people especially professionals work a certain way and won't do anything outside their narrow window. I have the manlift so this is a huge game changer. Owning your own manlift and having some common sense as to capabilities gives a freedom few can or will ever experience. All the roof penetrations will be custom fabricated thimbles with the snow and corrugated roof panels in mind.

.thumb.webp.7dac0895fe454e84372d68d3149f0537.webp)