-

Posts

11 -

Joined

-

Last visited

Recent Profile Visitors

877 profile views

-

-

@SnailForge If you don't mind me asking, how much does a gorgeous Damascus straight like this go for?

-

I picked it up from the guy for $220. He was happy with letting it go for that, and so was I. We'll see how she works soon! The blower works great as far as I can tell. Just a little push on the handle and she spins a few times around before stopping. I'll get some more/better pics up also so you guys can check her out.

-

Crazy Ivan taught me a good way to get these leafs to look good and to forge well. Start off by giving your stock a nice point flat on the face of the anvil. Second, you'll put the tip over the edge of the anvil and hit it half on, half off (if I remember correctly) to give the leaf/head some defined shape and separate its shape from the stem shape. In your last picture, see how the back of the leaf sort of folds on itself? Avoid this by taking your hammer at a softly outward (toward the head angle) and tapping/pushing the metal forward, giving it a sort of forward sloped angle. This stops the metal from bending backwards on the stem when you hit it straight down in the future. Not to go backwards, but when defining the head make sure you hit on 2 sides (picture a square [ ], you want to hit on top and right side) rotate every good hit or two. This keeps it consistent and your stem won't drift on you. Over the edge of the anvil separates the leaf from the stem and hitting on two sides makes the leaf kind of triangle. It'll look something like an arrow head, high in the direct middle. From there, you'll want to shape the stem - make it as long as you'd like it to be, and use the leaf head as a guide - aka push the 'leaf' head over the edge of the anvil and pull it back until the defined edge is against the edge of the anvil, holds it pretty nicely. once you've got your stem squared off and at the length you want, you can shoot for forging the leaf itself. Set it flat on the face and hit at the high point, driving it down in the center and pushing the iron outward away from the center of the leaf. This spreads it out and gives it some shape. Once you've got that down a bit, you can switch to the cross pein and use it from the inside and work the steel outward as thin as you want the leaf to be. I'm still learning this myself, so I may have missed some important detail/step - or even got this slightly out of order (this was all from off the top of my head from a recent lesson) but my first leaf looked a whole lot like a leaf. Hehe when you're taking square stock to round for the stem (if you are), takes the 4 sides and hit on the corners, flat. This will give you an 8 sides stem, then do this again to make a 16 sides steam, and then gentle hits to round it the rest of the way. Aside from that, a few notches around the sides and some chisel detail and you'll be looking at a leaf. Personally, I flipped mine over and gave it some wavey shape with my ball pein, which looked pretty decent. Honestly, you've been doing this longer than I have - so maybe I'm not the best person to give advice, this is just how I was shown! Haha. Hope it helps even a little bit. :]

-

Thinking about picking this guy up. The fella selling wants $300 OBO. He days the blower works like a dream. How's this all sound to you guys?

-

Sounds good to me.

-

I need to get myself a hammer that'll work for blacksmithing - currently I only have a standard nail hammer. I am have a friend picking me up a nice brake drum to build into a forge, and I'll be grabbing a few pipes to put together and make it work. I plan on grabbing a hairdryer (like Frosty said) and maybe work on picking up a decent hand blower after that, although I could use a bellow too I suppose. At this point, all I have is an Anvil and my interest. I'm an Engineer, so I probably have a number of tools that I have/can get for work that would work for this also. Looking into getting some kind of grinder also, I hear Harbor Freight has/had a deal recently to get one for under $20? Crazy, hope I didn't miss it. Once I get the forge pieces, I'll be looking to build a stand for my Anvil, so I can start sighting in the necessary height for a solid hit - wrist rule seems fair to start. Don't worry! I've read through this same advice on here a number of times! The only things holding me back are a worthy hammer, and a forge! Haha I also need to decide what material I'm going to use in the forge. Charcoal seems like a fair start, but I was considering going for coke or some kind of blacksmithing coal - I mean this is Pennsylvania, right? Lol What do you use, Daswulf?

-

Thanks guys, I'm definitely going to do that. I could certainly use the guidance and example. I'll be doing some more research today on what I need for the forge so I can really get started. Outside of that, I just need to work on getting the tools together and I'll be set. I'll probably have questions, but I expect the kind folks on here will all be happy to answer them also.

-

I remember reading on here that you're around Pittsburgh also. I'm almost downtown, I'm so close. Haha I live in Beechview/Dormont. Just off of West Liberty on the south side of the Liberty tunnels.

-

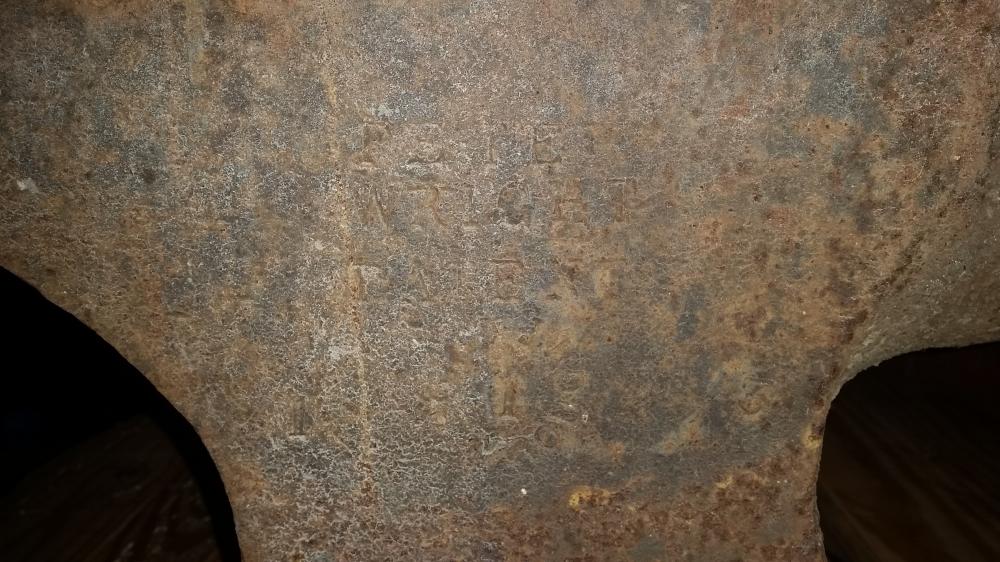

Hey everyone, I'm Josh and I'm from Pittsburgh, PA. Chemical Engineer by education, Controls/Mechanical/Electrical Engineer by career. Just starting out in putting together my own little set up and I happened upon a nice find today - a neighbor overheard my talking about looking for an Anvil and told me that I could have her old one for free. She bought herself a much smaller one, so she didn't need this one and it was just sitting. Turns out it's a Peter Wright. She says it's about 100lbs but I'll have to get it on the scale to know for sure. Says "1 1 3" on the side along the Peter Wright Patent symbol. Any questions about it? I'm happy to take more pictures. There does seem to be some minor damage to it, but honestly I'm just starting out and I'm sure it's nowhere near as bad as I think it is - since I'm only just starting anyways. Here are some pictures! I'll be looking into the safest way to clean her up tonight, as she's been outside for what seems like a while. Edit#1: I'm told by Dale Russell that "1 1 3" = 143 lb ... the first 1 = 112 lbs , second 1 = 28 lbs , 3 = 3 lbs. I appreciate the information, Dale! Looking forward to doing exactly what Dale suggested next, which was to "hit it with wire brush to get rid of some of the surface rust & get pounding hot iron on it."

-

Welcome to Pittsburgh! Sorry for such an unfortunate initial reason to stay, but glad things look like they're slowly working out for ya.