Ron Hicks

Members-

Posts

376 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ron Hicks

-

How do you make Rivets??

Ron Hicks replied to Ron Hicks's topic in Blacksmithing, General Discussion

Thanks Guys I wasnt for sure about length and was going 2 X thickness of rivet I forgot about the Hofi jig & thats what I will make I would like to buy some rivets and will look for them. If I were to make a rivet header is there a rule of thumb to go by to make the head size? Thanks Ron -

Ive been trying to make Tongs & want to know how to make Rivets. I made what I thought was a Header not use If this is right? 1/4 in. thick steel with a 3/8 hole. I stuck a 2 in. long X 3/8 round in it & left 1 in. sticking above & only heated this end with torch. It made a nice head but the under side I held on the anvil upset enough not to remove. Can some one help me Thanks Ron

-

new forge- was it worth it?j/k

Ron Hicks replied to Bear's topic in Blacksmithing, General Discussion

Bear you got a deal nice forge -

Im trin to go heavy duty with what I have on hand- its all out of 1/2 in. I cut from an I beam. The dies are cut from a roadgrader blade-man was that some rank stuff to cut with a torch PU! The grader blade has a good amount of carbon in it ( sparks when grinding) the dies are 2 in. wide X 1/2 in. thick & will weld on some mild steel on top. I need to cut a base plate and ready to weld it together I will cut the dies into and shape after its together. Ron

-

yes cooter I would get all of you can and yes bust it up thumb size or a litte bigger

-

That is pretty good stuff . he has like 2 hands on his arms & 2 hands on his legs the guy welding must have some tough fingers - I dont think I could do that

-

Thanks guys Ill get something thicker I just thought the 1/8 would work

-

From the album: Ron Hicks

-

Thanks Bear & JWB That helps Ive got it about the right size. I am also wondering if it should set center of the anvil? I cut the sides from an I beam almost 1/2 in. thick and have an old blade from a road grader thinking about making the dies out of it- also 1/2 thick. Im gona try cutting with a torch 2 in strip from the blade and then heating in forge to flatten. Is 1/8 in heavy enough for the bottom plate that sits on the anvil? I may end up with a big mess Maybe I should have bought new materail instead of junkin Ron

-

I want to make a Smithing Magician and could have sworn I seen one in the Gallery but cant find it. Thanks Ron

-

Cooter Hardening and Tempering is 2 different things Hardening is getting the steel hard & brittle( like a file or glass) Tempering is taking some of the hardness out so the steel is tougher and not as brittle. Using color to tell temp. is kind of tough( what looks red in full sun might look orange in the shade or even brighter in a dark shop.) You need a magnet - heat the steel and check it with the magnet, when the steel gets into the dark red start checking it with the magnet.As the heat climbs the color get brighter - when the magnet just stops sticking to the steel its called non magnetic (on the Tempil Guide Ac1 on heating &Ar1 on cooling). Depending on what steel temp. is different but with a magnet when it becomes non magnetic thats the temp. to Harden at. Non magnetic & hotter is where you want to forge also(depends on the steel) Theres way more to it than this but will get you started Look over the Key To Steel link I gave you on heat treating + lots of info. that will help you. Maybe others can explaine it better and will post Ron [ABANA] Tempil Guide Link removed at the request of anvilfire KEY to STEEL :: Articles

-

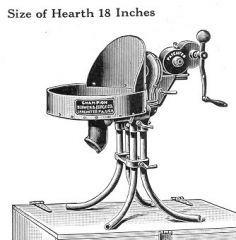

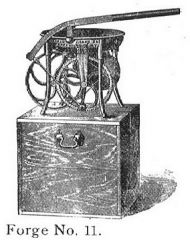

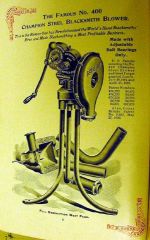

Cooter What you got going there would be better as a coal or charcoal forge not a gas forge. Look at this forge on ebay it is a coal or charcoal ( solid fule) you can see and get the idea. eBay: 20" Blacksmith Steel Coal Forge Pan & NEW Blower N/R (item 250083725196 end time Feb-18-07 19:30:21 PST) How to Build a Coal Forge Plans Now if you want to do a gas forge here is a few things to look at lot more to a gas forge and a burner. Gas Forge Burner plan and links HABA Houston Area Blacksmith's Association Sept 2003 Forge Construction THANKS GLENN:)

-

cooter If you went with charcoal or coal for just a quickey forge You could stack bricks around the flue and use a pipe to get the air in the fire for the air supply you could use a hair dryer duct taped to the end of the pipe. Just prop it on something so the pipe angles down in the fire. This would be like a side draft- if it comes in from the bottom its a bottom draft. this is a side draft With gas forge you need to build a burner , insulted shell . Glenn made a forge called the 55 Forge its a bottom draft (BP0133), and another that was side draft (BP0238). Any how easy to make. You can use other things for flue some even use corn. Don't use anything galvanized fume fever is bad news.

-

Cooter If it were me I would rig up a little forge out some junk and play with it - sure would make things easier Use some charcoal for fuel, play with it a little even if you don't forge with it use it fro the heat treating just trying to help:)

-

cooter just looking for info. thought you might like to look Fish Gigging eBay: Fish Gigs Spear or Fishing Gig Hand Forged by Don Baker (item 160084280381 end time Feb-20-07 17:17:34 PST) I may try to make one myself

-

Cooter go to the home page http://www.iforgeiron.com/ the tabs at the top click on Blue Prints (BP) Ceramic kiln i would think lots of $ you can make yourself a forge from found scrap cooter I looked and did not see a BP on a forge ( not sayin theres not one may have over looked or its not online yet) Look here there is a few forges gas & coal http://www.iforgeiron.com/gallery/showgallery.php/cat/503 Really not much to a coal forge need something for the coal to burn on with an air supply under the coal.

-

cooter why not make yourself a forge? you can use charcoal - coal- gas. Easy to make & would make things eaiser for you you can do everthing you want to do . I think there is a few BP,s on making a forges

-

If you use a round punch like a mandrel you can spread one end out bigger to make it tapper

-

Need Opinions On Type Of Steel

Ron Hicks replied to cooter's topic in Blacksmithing, General Discussion

cooter I took a few pictures from a old book. Poor old thing is about gone they are from Practical Blacksmithing Volume III 1890 It will give you an idea how you could forge one If you change your mind Its not a Gig but a Manure Fork .Same idea