Ron Hicks

Members-

Posts

376 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ron Hicks

-

I was looking in BP's and seen a few on starting a Coal Fire but havent found anything on Tending a Coal Fire. Im learning on my own and finding out the hard way. I found some good info. about tending the fire at The Fire I know I have a lot to learn & Im not going to without a good fire. How about some pointers on Tending a Coal Fire I can get it burnin but keeping it clean, hot,& making coke with out a ton of fines in the bottom is another story. Thank You Ron

-

Czech hammer handle...Resetting a handle-HELP

Ron Hicks replied to keykeeper's topic in Hand Hammers

I dont think I like the conical wedges -I have a Peddinghaus hammer with one I need to rehandle,I cant keep the head tight wedge keeps backing out. -

Czech hammer handle...Resetting a handle-HELP

Ron Hicks replied to keykeeper's topic in Hand Hammers

Sounds like the handle is not big enough for the head-I havent ever use glue on a hammer handles and have fixed a few old hammers. In BP Jr has a demo on handles and is the way I do it also. All the new hammers I have bought seems the handles all come lose. Something that might help once you get your handle in is soaking the head in linseed oil for a week. I looked at the hammers 1070 ht steel thats a good deal I thought. They have a Sweedish pattern also. I look at the same ones with good handles $50.00 I think I can do my own handle for $40.00 -

The only suggestion I have is more pictures Wow that is Very Nice I would like to see more of it Great Job Ron

-

Hi cooter Did you get the forge working ? Havent heard from you Ron

-

I think I may trash the handle its to good a blade to chance- Ive allways had trouble with a full hidden tang getting the handle to look right. I just hate to waste such a good looking chunk of Walnut.

-

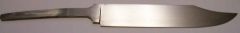

This is a knife I forged from a bearing race last spring thinking about finishing it. All hand work files, hand sand,edge harden & tempered.Its a through tang. I brazed sheet brass to make top furrel & NS pin stock flattened and brazed for the rings. The pomel is sheet brass also made a flaired out furrel dish out a cap and brazed on. The guard is NS ,wood is from a Walnut stump. I have the handle is glued to the rings furrel and pommel - its not attached to the blade or guard. I want to take a little bend out of the guard and file it down to the sides of handle also kind of blend it in. What do you think about the handle??? I dont know If I like it or not??? Maybe a Pakistan Bowie? I was going to peen the tang to hold on the hanlde- But Im not sure If it will work. I have a 1/8 in gap between the end of the wood and inside of the pommel where I wanted to peen the tang.I thought I would fill the void with JB Weld & when dry peen the tang down. Think the JB Weld will hold up ?or dent in the brass. Also If I were to peen it how much tang do i need to peen? I left it long. I can not take off the pommel its glue on. But I can make a new handle What ya think? Ron

-

Good for you They say the KMG is about as good as it gets Like to see some pics. when its set up how big a motor are you using? Ron

-

OK Guys I give - Making Chain isnt fun anymore I hate it!!!!!!!! 20ft. of 3/8 rd bar trashed out - bucket full of clinkers ,burnt, smoked,wasted coal.Time to walk away & leave it be Im to uptight. Sorry to bother you all and thanks for all the help everyone gave me, sorry I have wasted your time. Ron

-

I guess Im just hard headed - Ill keep at Has anyone tired making chain like in the link?

-

I would not care to have a Panther any where around little kids. I bet somethings worng for it to come up that close - Ive only heard them Squal never seen one Good old 30-30 might just be the thing

-

ttt ??? ???

-

I keep it in the upper 1/3 of the fire - The hand cranked blower is Royal you can see it in the old pic. Im getting welds and think I must not be making the scarf right- I cant seem to get the ends welded - it welds in center just the very tiny ends of the scarf is where I have my trouble. I tried today thinning the ends down & still having same problem. Ive got to be doing something Wrong ,I know the guys that made chain did spend an hour on each link with 4-5 welding heats. Im getting welds and think its my scarfs thats the problem Can you see in the pic. what Im talking about??????? Look at the top of the links . I must not understand this book Making a Chain :Farm Blacksmithing Its welding first heat all but the very ends Thomas have you made chain like this how did you shape the scarfs?? Ive been making pretty good Forge welds till I started foolin with this chain Ron

-

From the album: Ron Hicks

-

Open fire - I have a Champion Whirlwind fire pot 9 X 11 X 4 1/2 deep. Ive been filling the pot with coke level with top for the chain. So I know how much coke I need - should I keep as much coke on top the fire pot as in it, with wet coal banked on sides and back? Does the color of the flames tell you If it a comsuming fire when the blower is on? I have a Orangeish Redish flame. Other than the thick ends on my scarfs is this right for chain?:confused: This is on Chain Making and what Im tring to do. Making a Chain :Farm Blacksmithing I wish someone could do a scarf for chain and show a picture Thanks Ron

-

This first picture I tried to get a edge view of the scarfs. They are scarfed on opposite sides of the bar. Second picture is of the side of bar. I give the ends a good wack on the horn to bend them in. Then heat and bend into like a tear drop shape with the scarfs together for the weld. Ive tried bending the U first ,scarf ends, and turn in . Third picture is the links welded. I have the bad ends all to the top of picture. I get them welded in the center first weld I reheat 2-3 more times tring to get the ends to weld . Ive made 10 links so far and only had 1 weld with out no seem at ends of scarf. I twisted 1 apart in the vise they are welded but with the end not welded that is where the tear starts. I started with a good size coal fire and had a hard time working in it.I had better luck with just enough coal to fill the pot. I turn the links over every few seconds and use flux. Ive tried to weld at heat just before sparks - the best weld Ive gotten the link had sparks shooting off. Ive been having the same trouble on other welds also and takes 2-3 heats to make it right but I cant seem to get the chain to weld on down. Thanks Ron

-

6 in. X 3/8 rd. Welded Links ends of scarf not welded

Ron Hicks posted a gallery image in Members Gallery

From the album: Ron Hicks

-

From the album: Ron Hicks

-

From the album: Ron Hicks

-

Roger I really like your posts you allways show us great things Thank You Ron

-

I tring to learn to make chain. I dog ear scarf and bend to lap each other & forge weld. Im having a lot of trouble getting the ends of the scarfs welded down. Ive gotten a few welded good but took like 4 heats. Most of the links Ive made are welded in the center and not at the scarfed ends. Thanks for the help Ron