-

Posts

19,404 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JHCC

-

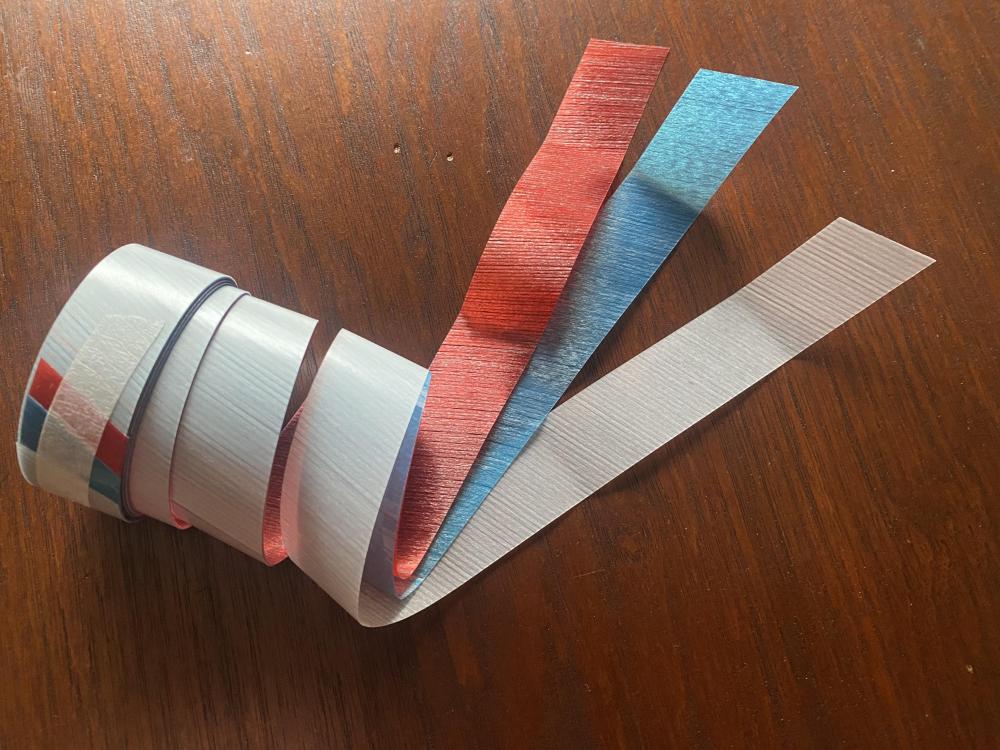

Long overdue update: the worn-out belt option didn’t work particularly well, nor did experiments with replacing the polyurethane glue with cyanoacrylate. The version of removing the grit to use the belt material itself instead of splicing tape was a total bust, as I didn’t have any success removing the grit from the belt So, I just got a shipment of one yard each of three different weights of splicing tape from an eBay vendor in China. Including sales tax and with free shipping, total cost was a hair under $16. Note the filaments running diagonally across the tape, to provide maximum strength in the direction of maximum stress. It’s very thin, but apparently very tough While I don’t have the specialized adhesive or heated press that one is supposed to use, I figure that I’ve got enough tape to be able to experiment with different adhesives and see what works best. More to come.

-

Mail call! Three different weights of grinding belt tape, shipped from an eBay vendor in China. For further discussion, see my Splicing grinder belts thread.

-

We had Samoyeds when I was young. Lovely dogs, but lots of fluff at shedding time! Chows get a bad rap, but socialization makes a huge difference.

-

I just did a little quick Google research and found the site (commercial, so I won’t link it here) for a German vise manufacturer that claims that the parallel-jaw vise was invented in 1750. I suspect that they didn’t really catch on until casting and machining technology had advanced enough to make such vises reliable and affordable. (That same site says that the first cast iron vise was made in England in the 1830s.)

-

I’ve seen that combination in a lot of older shops.

-

That hammer’s gonna get lost in the straw.

-

So, I drove down to Colonial Homestead in Millersburg, OH (in the heart of Amish country), where I traded a bunch of my old woodworking planes: For a bunch of new (to me) smithing tools: Two half-round swages (one handled, one not), three forming hammers (of different sizes and shapes), an all-metal adjustable bevel, a rather nice straight-peen hammer (with a rectangular face), and a steel block with a bunch of differently sized holes, which should be good as a bolster for punching holes. They have a great variety of tools of all sorts: blacksmithing, timber framing, cabinetmaking, woodcarving, leatherworking, measurement, layout, and more. Good selection of anvils in good shape for decent prices. Two things caught my eye that I didn’t get. One was a pair of tin cans full of old bits of metal for $300, which turned out to be a set of decorative punches and bolsters from an old-school tinsmith. Gorgeous tools, but out of my price range at the moment. The other was a nifty little combination pouring ladle and mold for casting lead hammers: Dan (the owner) is very clear that he wants to sell to people who actually practice the crafts, rather than those who want to pay premium for “antiques”. He gave me a fair deal on the planes and cut me a bit of a break on the items I picked out for trade. I’ll definitely be going back.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I can’t claim originality on this idea, which I borrowed from Kim Thomas. After posting the above photo, I added another bit of sheet that makes the catcher even more effective: The metal in this case followed me home from a friend’s remodeling project, but any thin sheet metal will do. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

-

A neighbor was selling an old steel scuba tank for $5. Not yet sure if I’ll make another bowl mold or maybe a blade quenching tank or what, but it was a good price.

-

This is the point in the conversation where Thomas would point out that large bellows were often suspended from the ceiling, both to save space and to keep the heavier-than-air coal gasses from settling in their tuyeres and blowing out their sides.

-

I used to deliberately back the blower up a quarter-turn in order to produce mild explosions, back when I was young and foolish.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Very nice, Rojo. I like that cuff, Mothman. Looks good both with the nonferrous decorations and without. I do have one very small suggestion. Next time you do something like this, go over the entire surface of the copper and brass pieces lightly with a hammer, just enough to break up the roller-mill-flatness. That will be more pleasing to the eye, and will harmonize better with the forged surface of the steel. -

Eugenio Monesma just posted another video showing a smith in Spain using this same kind of two-lung bellows. I’ve posted about that HERE.

-

This documentary short shows a traditional blacksmith shop in Alcántara, Spain. Please note the two-lung bellows, as well as the rather clever rig the smith uses when he doesn’t have an apprentice handy.

-

Tee Public.

-

Carpe momentum!

-

I had a great moment today, as I was having dinner with a friend who knows that I blacksmith. He asked, “Do you know Goya’s painting ‘At the Forge’?” I replied:

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Torch welding also has some very interesting aesthetic possibilities. See the early 20th century work of Edgar Brandt (an early adopter of torch welding for its own sake) and the more recent "puddle people" of Peter Renzetti. -

Chop six inches off the legs, and make it the anvil for visiting children!

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I have a big pair of shears like that, which I used for 16 ga. and thinner steel before I picked up my more modern bench shear. Also good for trimming those extra-hard toenails. -

JHCC's consolidated Hossfeld Universal Bender #2 thread

JHCC replied to JHCC's topic in Cold Worked Iron and Steel

Made a pair of V-blocks to improve the working of the radius tool for round pipe. Also added some diagonal bracing to my handle extension. (Formerly part of a now-replaced anvil mounting system.)