Anthony San Miguel

Members-

Posts

192 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Anthony San Miguel

-

Begginer Projects

Anthony San Miguel replied to Forging Carver's topic in Blacksmithing, General Discussion

You're misspelling beginner. -

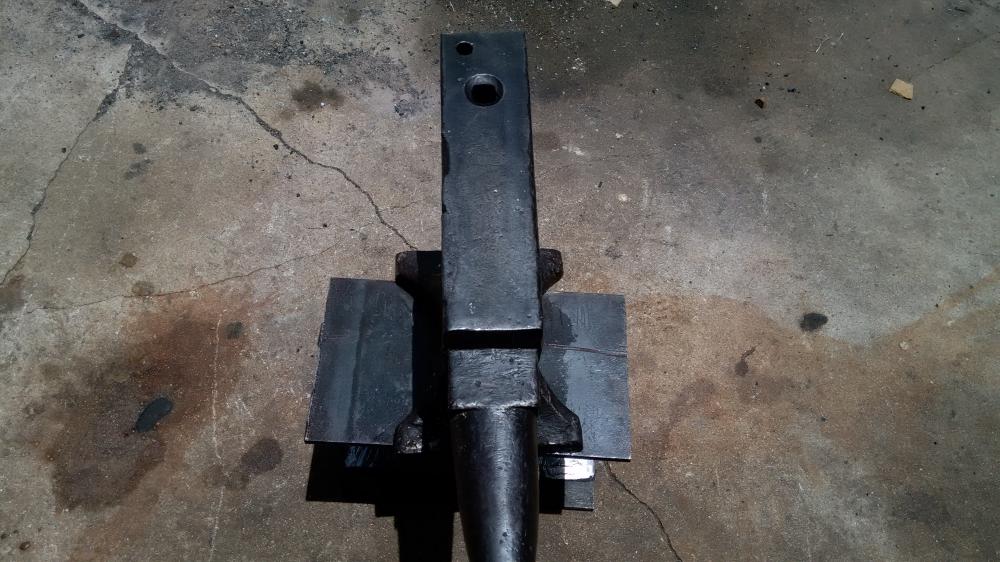

Thank you, Frosty. I'm building a stand for it tonight. Can't wait to feel what forging on a Trenton is like. I know it's a little louder than my other anvils but I'll bet that a few small, strategically placed magnets will help reduce the ring. As far as that edge being possibly repaired, I don't think it has been. The tool steel plate doesn't look like its been welded back on in the area in question. That edge doesn't rebound or sound any differently than any other edge that is over the mass. Either way I'm really glad I didn't let the anvil pass by. I saw these pics on my FB page and the smoothly radiused area around the hardy hole that looks intentionally made to me resembles this table/swage? that is being used to drift hammers. I wonder if this was my anvil's job in its previous life.

-

Thanks! If you are seeing the different color along one edge in the last picture I think it is more likely a streak from the cleaner/lubricant I sprayed on after wire brushing it. Or is there something else you're seeing that leads you to believe that? There is no reduction in rebound anywhere on the face over the mass.

-

I found this 100 lb Trenton made Acme anvil for $275 at a very unexpected location. The flea market. They were asking $350, which is more than the $3/lb price I'm comfortable with but I was able to haggle them down because after paying the $2 admission I only had $275 in my wallet. I'm very happy with it! The ball bearing test is excellent, around 90+%. Notice the angle above the cutting table. Does anybody have an idea why that would be there? Also, the radius around the Hardie hole looks like it was intentionally made by a previous owner. Awhile back I read that you can search for your first anvil for quite some time but after you get it they start turning up left and right and that has proven to be the case for me. This is #4 since I bought my first one earlier this year.

-

Anvil rebound

Anthony San Miguel replied to BifrostFarms's topic in Anvils, Swage Blocks, and Mandrels

The mass is under the face, not the heel or horn so those areas will have less rebound. -

Oh, okay, thanks. I know brine quenches are frequently used in low and medium carbon steels that wouldn't harden up well in oil. I thought it might be something as simple as that, the fact that you clean up the outer layer after quench. Just wasn't sure. Rust makes me cringe when I see it on something I made or a nice tool.

-

Is this because of the transformation that is taking place in the metal at that temperature? I'm just trying to understand and it may sound dumb, but I know if I accidently take my knife swimming in the ocean with me it will have rust on it that evening.

-

After quench, temper and finish, should any additional care be given to steel that's been quenched in brine or anything containing salt?

-

I have some turkey fryer oil that I saved from thanksgiving to use as a quench. What has kept me from using it is that I wonder about all the salt that no doubt is in it from the turkey and hushpuppies and everything else we cooked in it. Could that make the steel more likely to rust, especially the knives? Or am I concerned for nothing. I know that the oil gets cleaned off after the quench, but??

-

forged tools

Anthony San Miguel replied to Ethan the blacksmith's topic in Tools, general discussion

Thanks for sharing this. I'm going to try it this weekend. We have 3 wonderful scrap yards in San Antonio that allow you to scrounge and the two biggest are just down the street from each other. I ALWAYS find good stuff and I know I'll find some heavy duty truck axle. I don't have a power hammer but I'll still make good use of it. -

Champion Model H leather cutter.

Anthony San Miguel replied to Anthony San Miguel's topic in Everything Else

That devious, huh? Lol A while back my wife says to me that she wants to try a new hobby. I suggest leather working to her, thinking that one day when I start making nice knives she can make the sheaths. So I buy her a starter kit, leather dye, deluxe mallet, a few bellies and a few other things from Tandy to get her started. So she starts to watch the tutorials on Tandy's website and thinks it's neat but after trying it a while she loses interest. Maybe after I "donate" this machine to her hobby she'll have no choice but to accept it. -

Champion Model H leather cutter.

Anthony San Miguel replied to Anthony San Miguel's topic in Everything Else

This is great advise! Thanks! -

Champion Model H leather cutter.

Anthony San Miguel replied to Anthony San Miguel's topic in Everything Else

Yeah, I've been looking at those Christmas decorations for a while. -

Champion Model H leather cutter.

Anthony San Miguel replied to Anthony San Miguel's topic in Everything Else

Thank you guys, for the replies. I have seen it described as a combination splitter/cutter. I see your point Bigfootnampa. I did buy it hoping to sell it and double my profit to reinvest in something I could use. But I just wonder if it's worth it to me to learn how to use it. I'd hate to later on be in a position where I'm making a sheath or something and wish I had kept it because it does sound useful. But I'm running out of space in my garage! -

Which of these two anvils should I get?

Anthony San Miguel replied to Daniel67's topic in Anvils, Swage Blocks, and Mandrels

That Peter Wright looks like it has more than just the edges welded up. It looks like almost half of the face is welded when you consider the 3 edges that look like there is welding done. -

I saw this old leather cutting machine at an antique shop around 2 weeks ago and a quick Google search showed one for sale on Craigslist and eBay for $400. I realize that is the asking price and doesn't mean it sold for that price but the poster also said similar ones sell for $550-$800. Well I bought it for WAY cheaper than $400 figuring that I could probably double my investment pretty easily, even if I just sold it for $200. But now I'm wondering if I should keep it. Maybe I could make nice sheaths or holsters or who knows what with it. Does anybody know anything about this machine? It's a Champion Model H. Everything turns fine on it. I don't have a lot of extra space in my garage for something I couldn't really use and I want to buy or make a small forging press eventually. Any thoughts or info appreciated.

-

Parks 50 is highly recomended. A place in Dallas sells it. I'm sure there are other places and it sometimes sells under a different name but most knifemakers call it Parks 50. It's not cheap though and I believe the smallest volume it sells in is 5 gallons. If you aren't going to keep making knives I would use warm (130°) canola oil.

-

Anvil Stand preference

Anthony San Miguel replied to Takeru691's topic in Stands for Anvils, Swage Blocks, etc

I like this answer. lol -

If you can get a hold of a few good quality files with sharp teeth it doesn't take as long as you think to grind out a knife. If you learn to draw file with good sharp files and develop a rythym that steel stock turns into a knife before you know it.

- 15 replies

-

It followed me home

Anthony San Miguel replied to Glenn's topic in Blacksmithing, General Discussion

A guy was selling this Craftsman 1x42 at the flea market today for $35. I couldn't pass it up. Almost all steel construction. -

Some old neat shop tools

Anthony San Miguel replied to GottMitUns's topic in Tools, general discussion

These two are at the Boerne Agricultural Heritage Museum where the last Balcones Forge meeting took place. -

246 lb Austrian Anvil

Anthony San Miguel replied to Anthony San Miguel's topic in Anvils, Swage Blocks, and Mandrels

Ahh, yes, I've seen that. Thanks for reminding me.